Disk-type permanent magnetic speed regulator

A permanent magnet governor, disk type technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of electromagnetic interference, many fault points, short life cycle, etc., to reduce mechanical friction and wear, and accurately control the size of the air gap , The effect of improving the stress situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

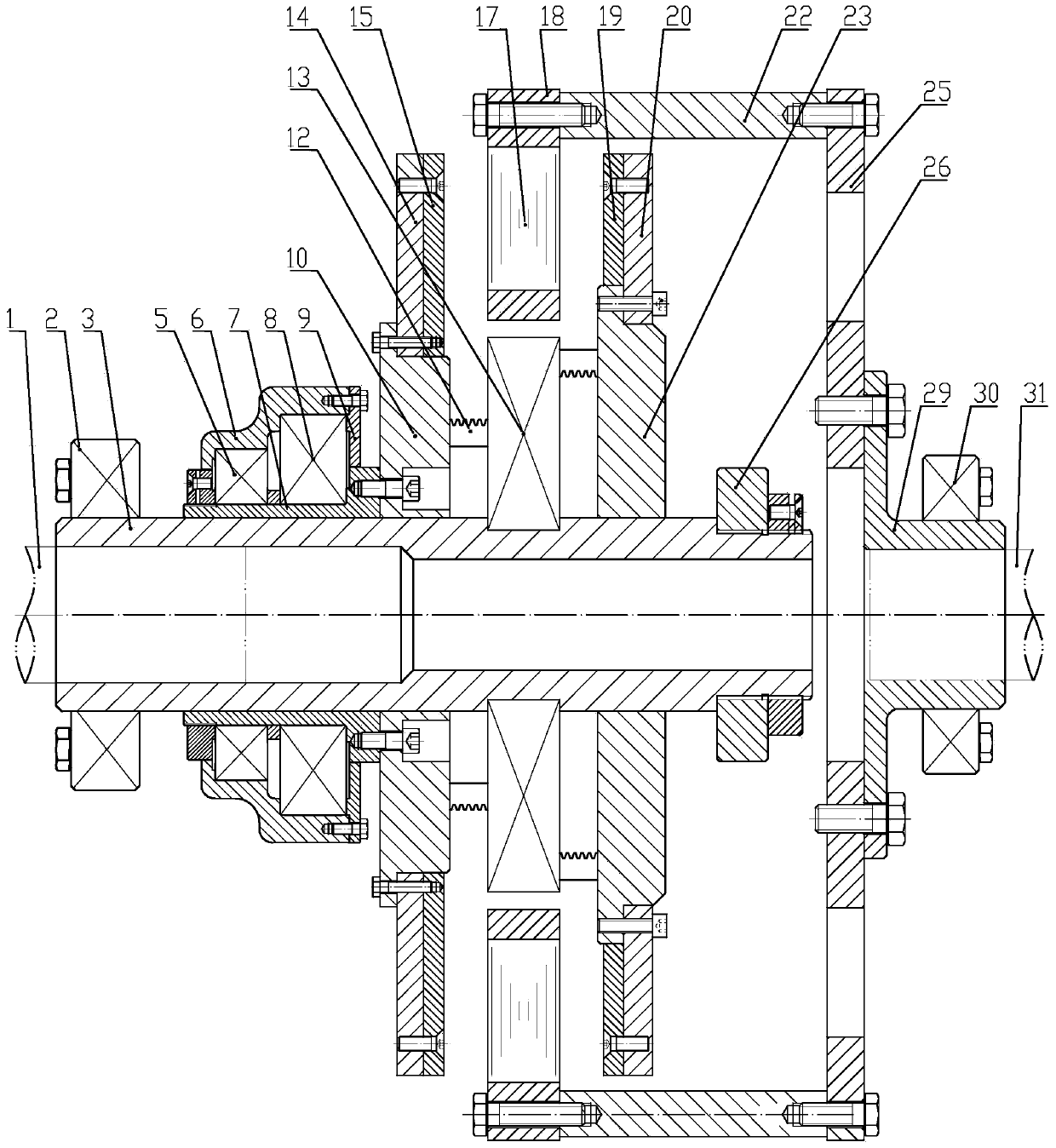

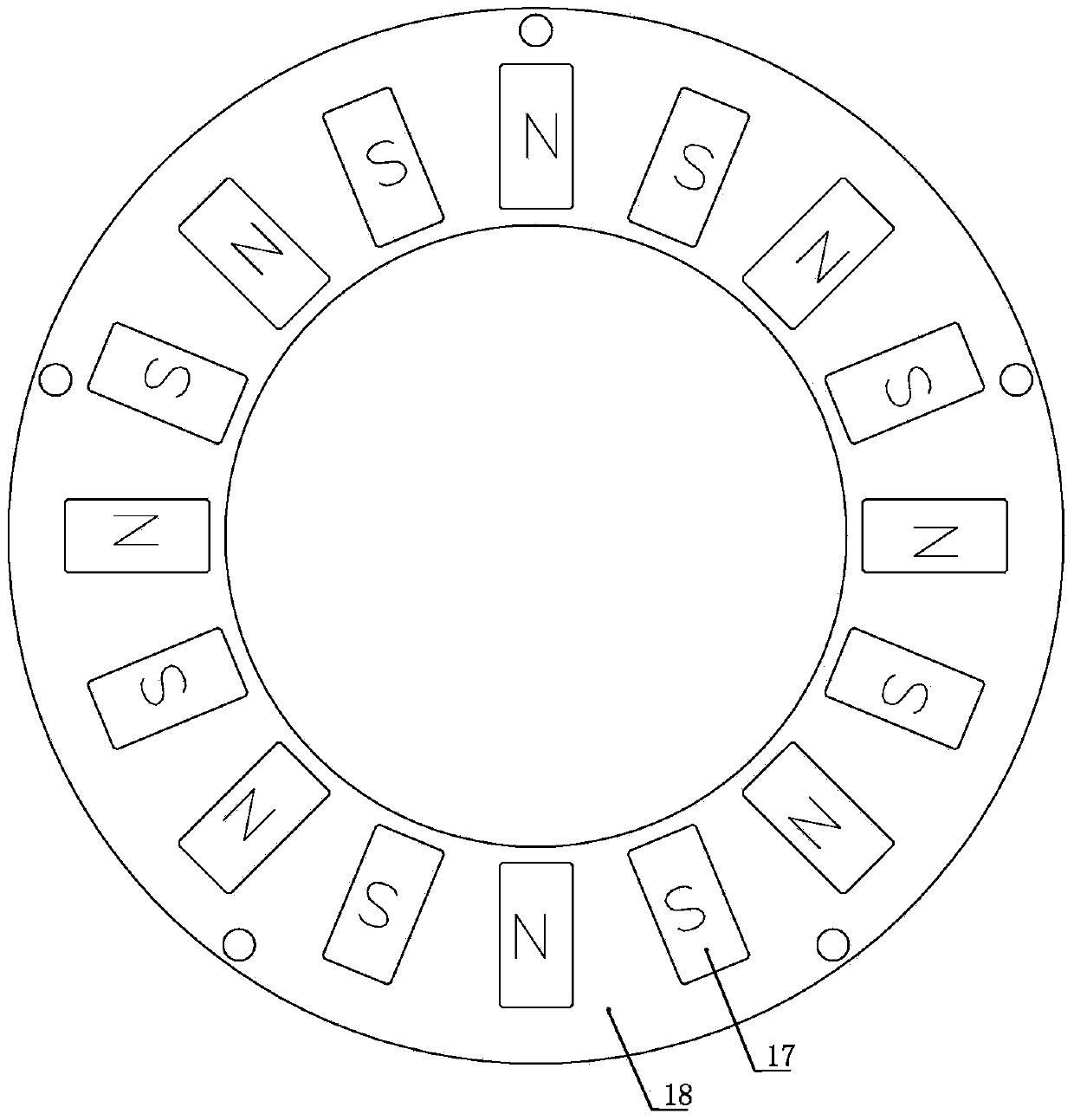

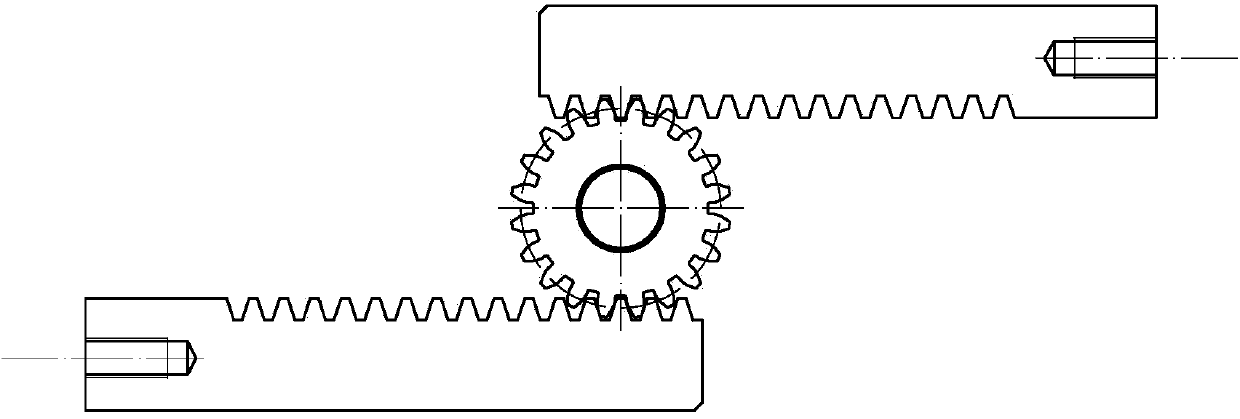

[0028] see Figure 1-Figure 5 , the disc-type permanent magnet governor of the present invention includes split and coaxial first shaft 1 and second shaft, the first shaft 1 is sleeved in the first shaft sleeve 3, and the first shaft sleeve 3 is externally sleeved for adjustment Speed mechanism, slider Ⅰ, support frame, slider Ⅱ and limit plate, the speed regulating mechanism is connected with slider Ⅰ through bolts, the support frame is installed between slider Ⅰ and slider Ⅱ, and the support frame is connected through a rack and pinion mechanism Connect slider Ⅰ and slider Ⅱ; slider Ⅰ connects conductor plate Ⅰ and steel plate Ⅰ through bolts, and slider Ⅱ connects conductor plate Ⅱ and steel plate Ⅱ through bolts; the limit plate is installed on the first shaft sleeve 3 far from the first one end of axis 1;

[0029] The second shaft is socketed in the second shaft sleeve, and the load connection plate is installed on the second shaft sleeve. A connecting rod is installed...

Embodiment 2

[0040] see Figure 5 and Figure 6 , the speed regulating mechanism on the first shaft sleeve 3 of the disc permanent magnet speed governor of the present invention can be a chute structure, including bearing I5, bearing II8, inner casing 35, outer casing 38, sliding sleeve 7, bearing pressure Cover I36, bearing gland II39; the inner shell 35 is symmetrically opened with two helical sliding grooves in the same direction on the outer cylindrical surface, and the inverted groove shaft 33 and the inverted groove sliding sleeve 32 are nested and installed in the sliding grooves of the inner casing 35 , the outer shell 38 and the inner shell 35 are nested and assembled, and are connected by two pairs of inverted groove shafts 33 and inverted groove sliding sleeves 32; the bearing I5 is placed in the inner shell 35, and the outer ring of the bearing I5 is fixed by the bearing gland I36 , the inner ring of bearing I5 is fixed by lock nut I34; bearing II8 is placed in the outer shell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com