Case hardening steel material with little heat-treatment strain

A steel and area technology, applied in heat treatment furnaces, heat treatment equipment, metal material coating processes, etc., can solve problems such as inability to achieve, and achieve the effects of less vibration, high dimensional accuracy, and excellent fatigue properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

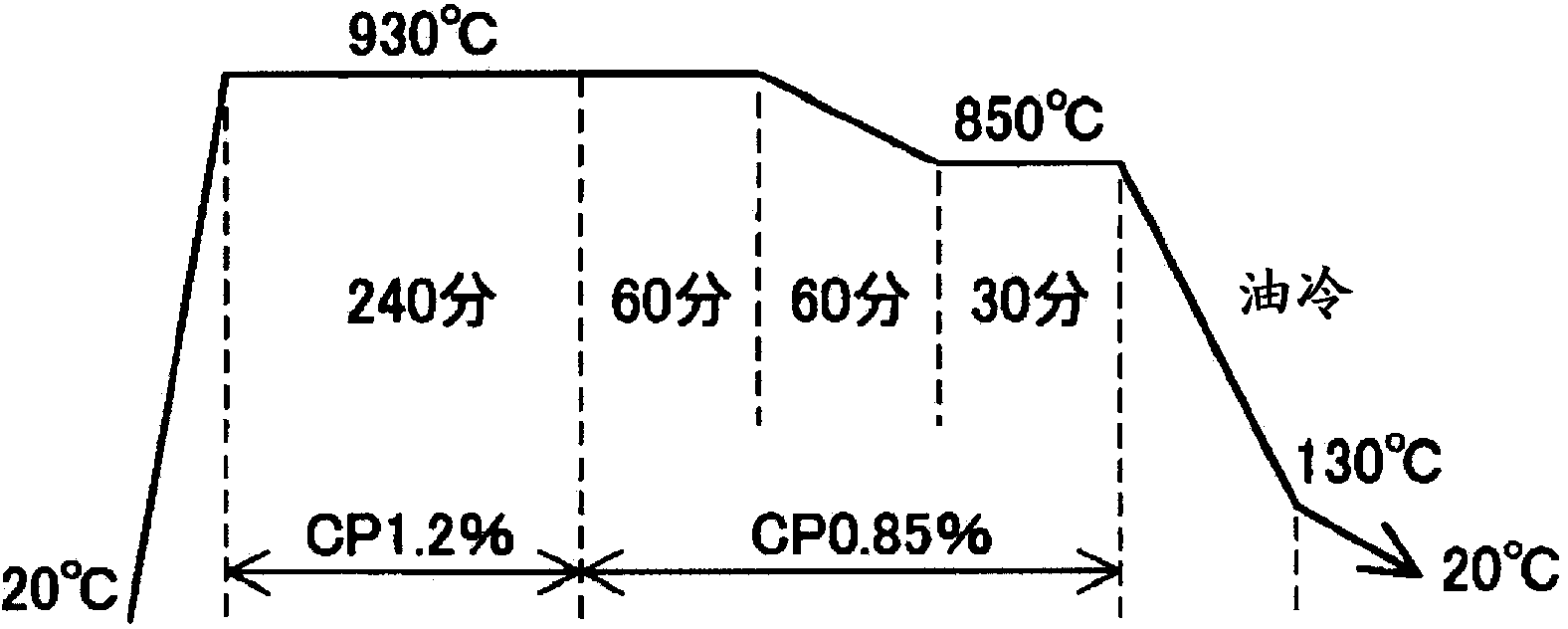

Method used

Image

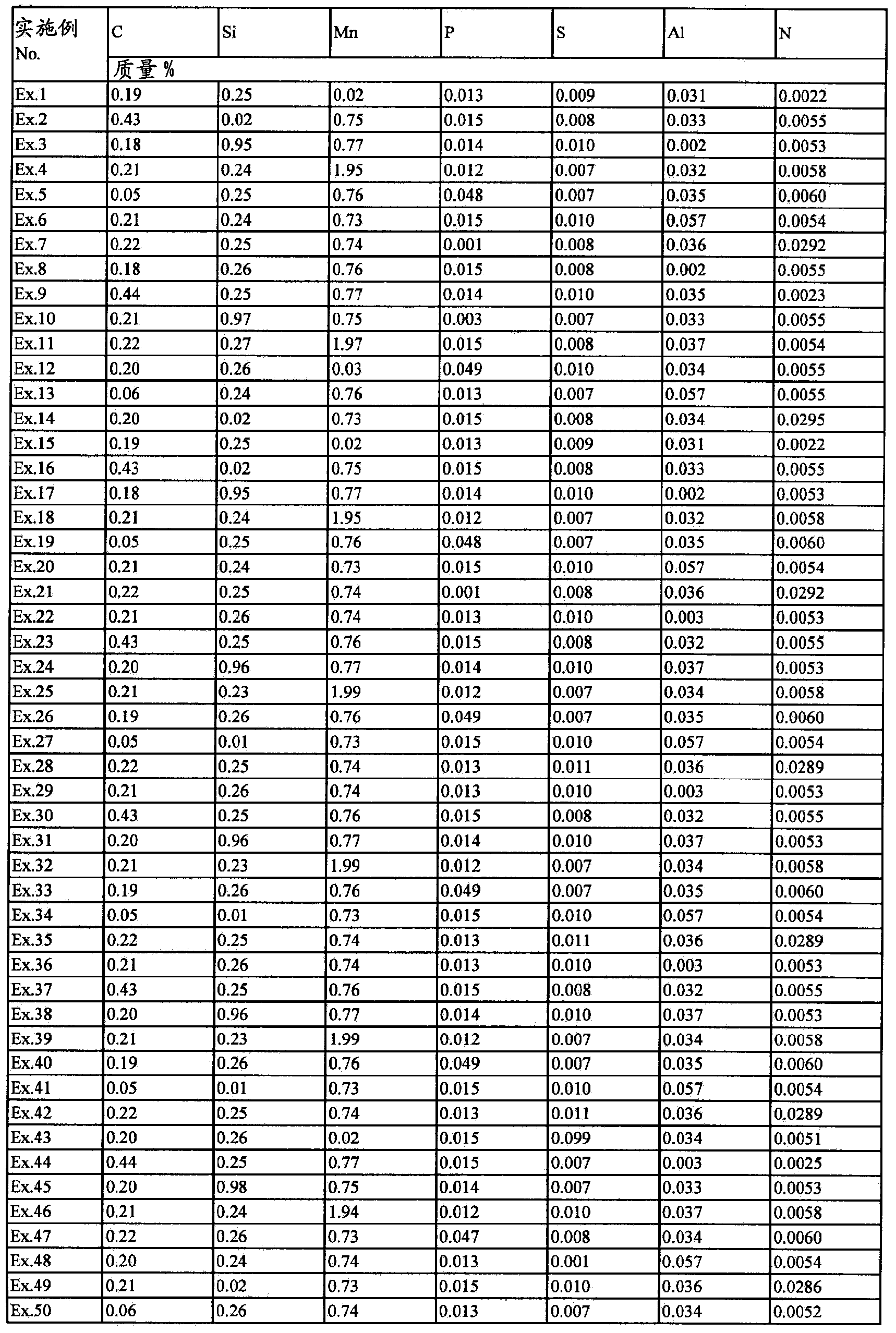

Examples

Embodiment Construction

[0056] In this specification, the present invention will be described mainly for application to gears, but the case-hardened steel material of the present invention is not limited to application to gears, and can be applied to mechanical parts whose surface layers are hardened by the above-mentioned quenching treatment. , especially mechanical parts that are strictly required to reduce the amount of strain after carburizing and nitriding quenching.

[0057] As described above, in order to solve the problems of the present invention and achieve the object of the present invention, the present inventors first carefully investigated the factors affecting heat treatment strain. As a result, it was found that in the macrostructure (solidified structure) of the cross section of the steel material, the following (a), (b), (c), etc. greatly affect the heat treatment strain:

[0058] (a) Decrease in C concentration;

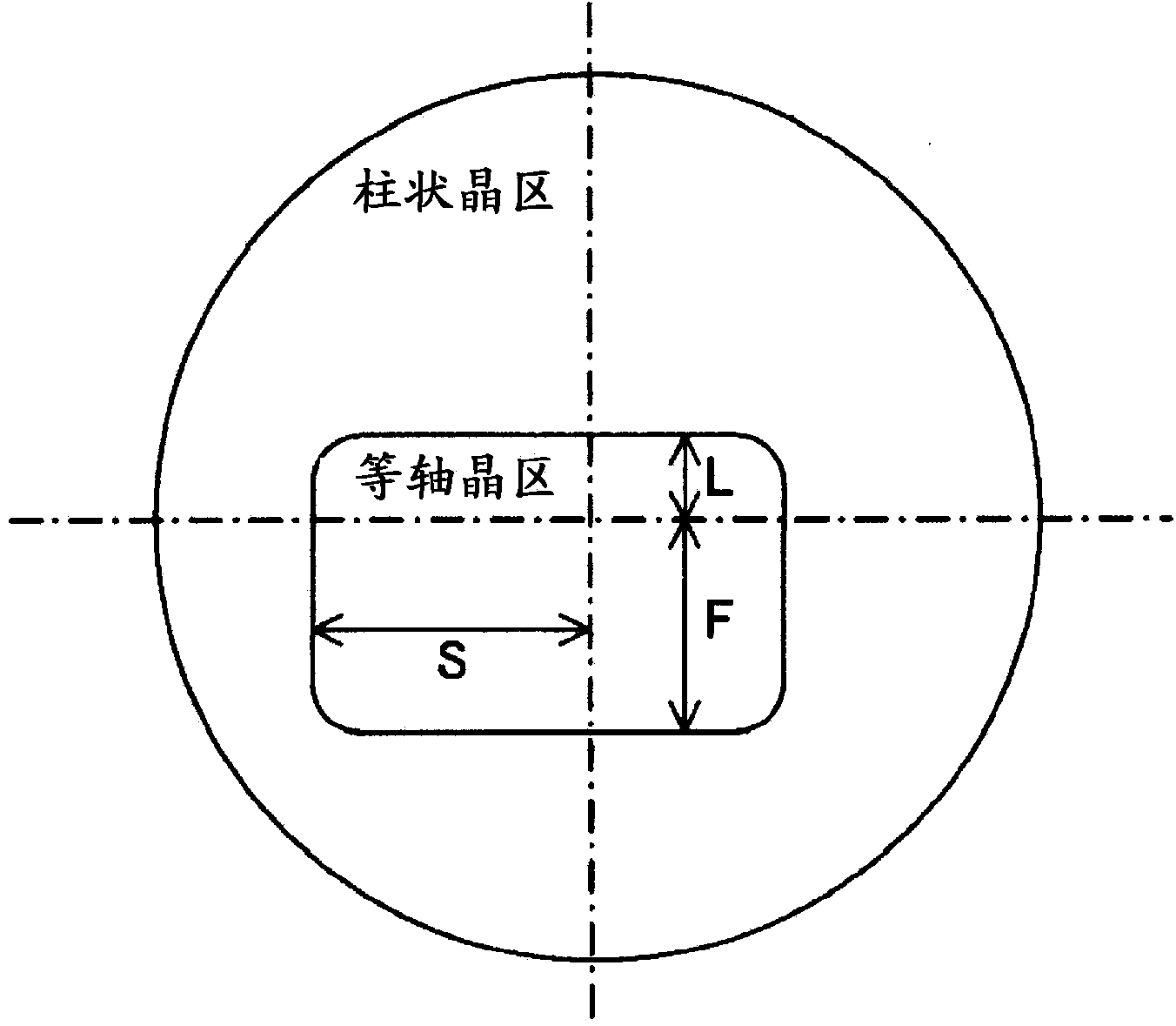

[0059] (b) the area and area ratio of the equiaxed domains where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com