Steel for nitriding and nitrided steel components

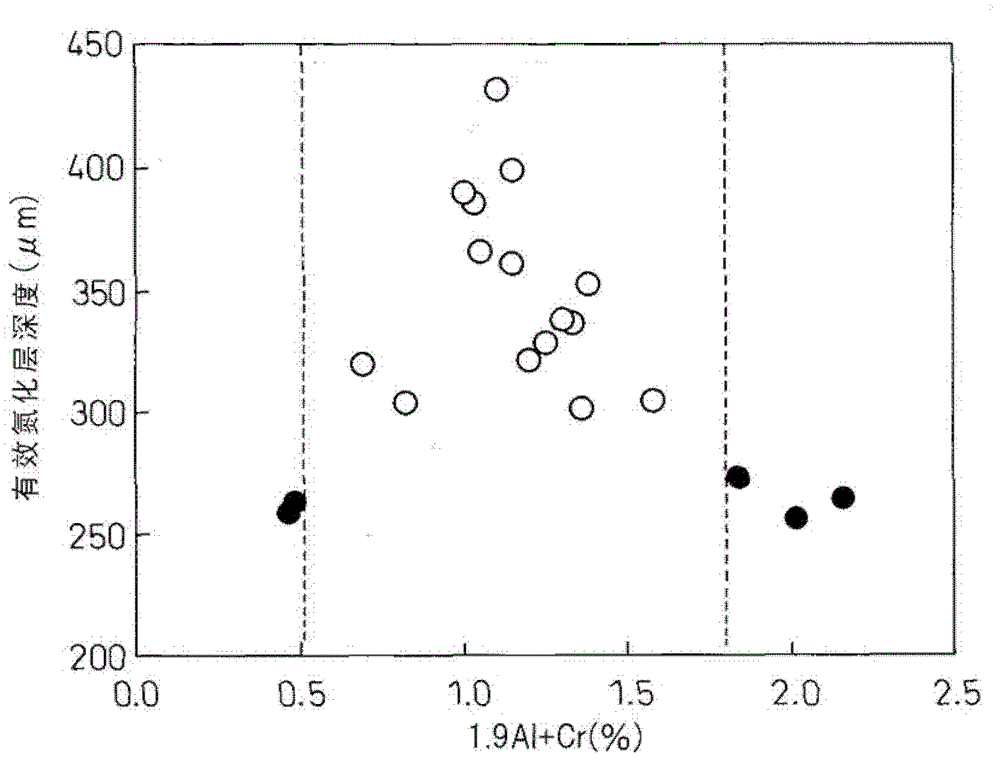

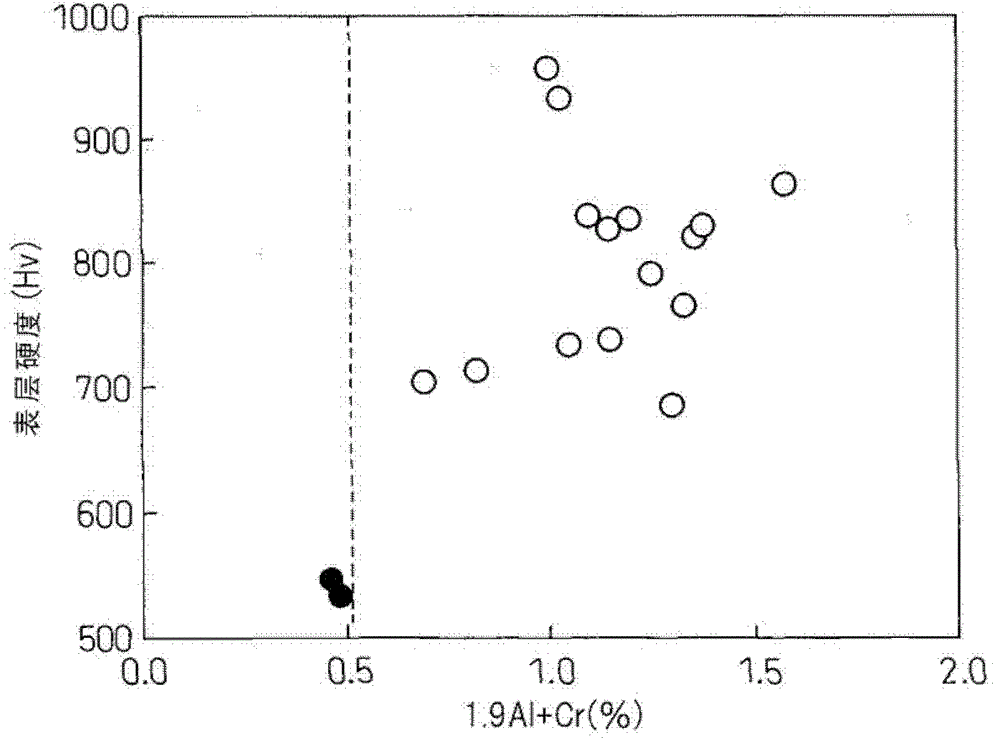

A technology of nitriding treatment and components, applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of slow nitrogen diffusion, achieve the effect of small heat treatment strain and improve fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0130] Next, the present invention will be further described using examples, but the conditions in the examples are examples of conditions adopted for confirming the practicability and effects of the present invention, and the present invention is not limited to this example of conditions. Various conditions can be adopted in the present invention as long as the purpose of the present invention is achieved without departing from the gist of the present invention.

[0131] First, steels having chemical compositions shown in Table 1 were melted. Underlined numerical values in Table 1 indicate that they are outside the scope of the present invention.

[0132] Table 1

[0133]

[0134] • Underline means that it is outside the scope of the present invention.

[0135] · A blank column means that it is intentionally not included.

[0136] Some of these steels were hot-rolled to obtain round bars with a diameter of 10 mm. In addition, for a part of steel, after heating and ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com