Squirrel-cage type two-stage cyclone solid-liquid separation device

A squirrel-cage, liquid separation technology, applied in the direction of separating sediments by centrifugal force, can solve the problems of increased frictional resistance of media, decreased processing efficiency of oil and gas separation equipment, and decreased effective utilization of storage equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

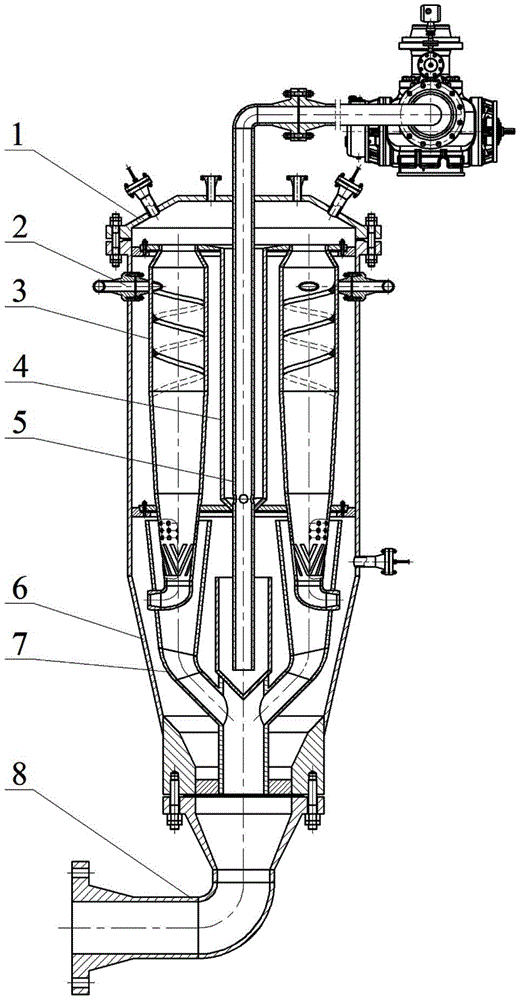

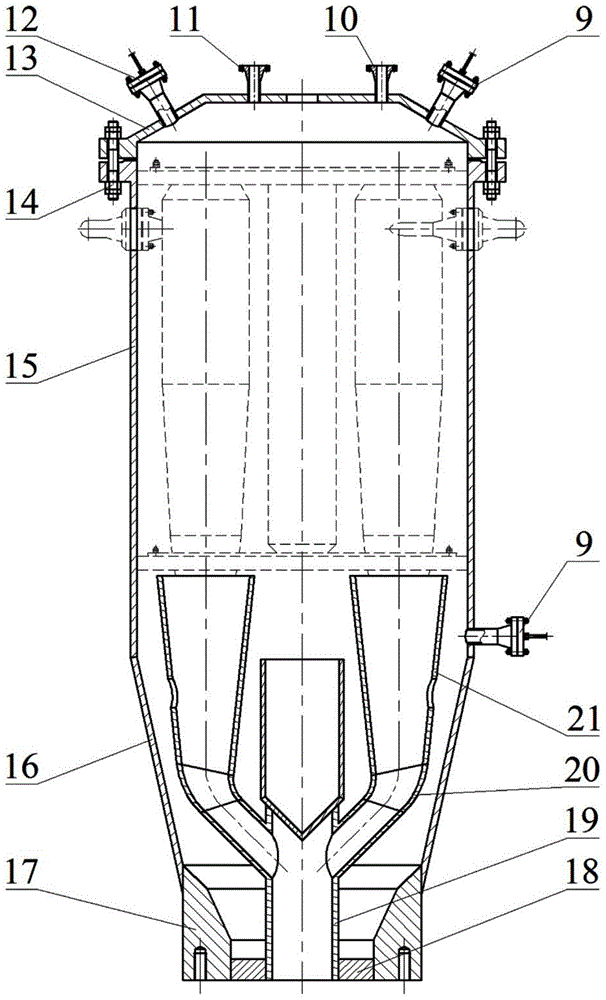

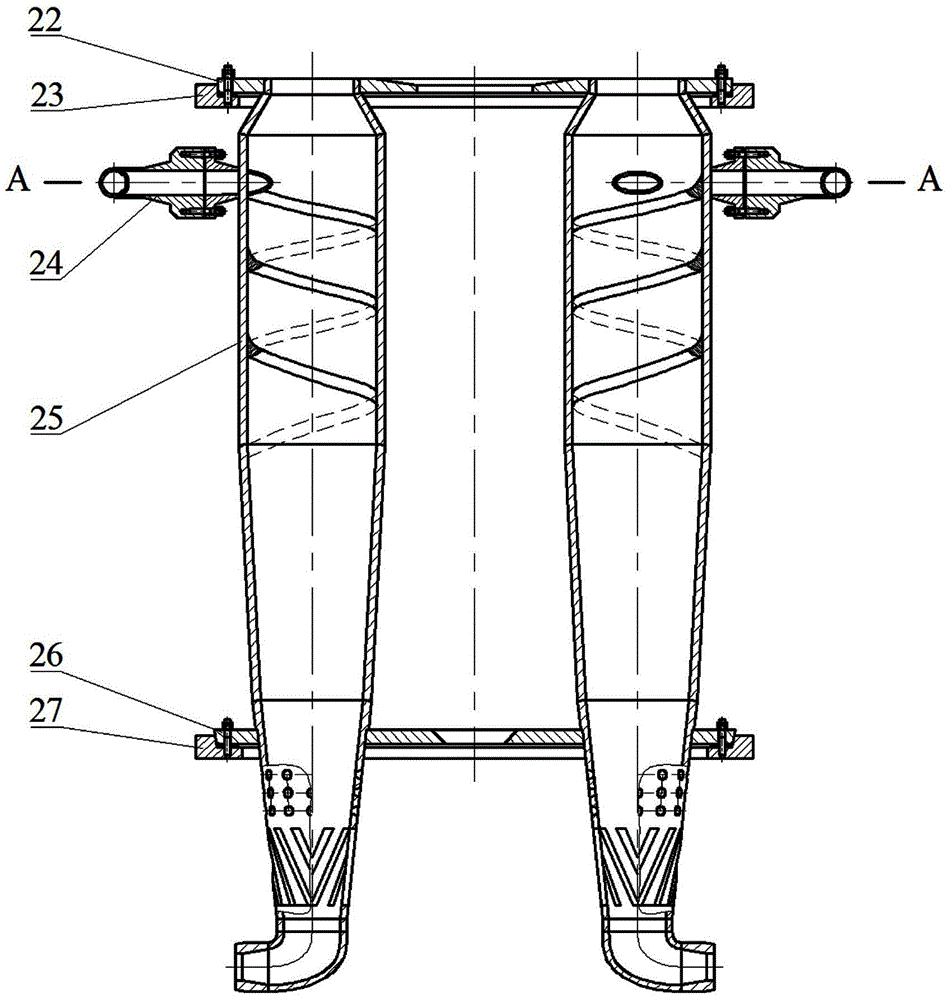

[0033] exist figure 1 Among them, the squirrel-cage two-stage cyclone solid-liquid separation device consists of a sand removal tank 1, a liquid inlet manifold 2, a squirrel-cage cyclone pipe assembly 3, a liquid collection pipe assembly 4, a liquid discharge assembly 5, and a secondary The cyclone tube assembly 6, the sand collection pipe assembly 7 and the sand discharge pipe 8 are composed. When assembling, first weld the lower liquid collecting pipe of the liquid collecting pipe assembly 4 and the sand collecting pipe assembly 7, then put it into the seal of the secondary cyclone assembly 6, and connect the sand discharge pipe 8 to the secondary cyclone assembly 6 through screws. Put the squirrel-cage swirl tube assembly 6 on the upper stage swirl tube assembly 6, then place the lower partition of the squirrel-cage swirl tube assembly 3 into the backing plate, and put the inlet manifold 2 and each swirl tube into the sand removal tank 1 in sequence after welding Inside, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com