A fixed fluidized bed reactor and its application

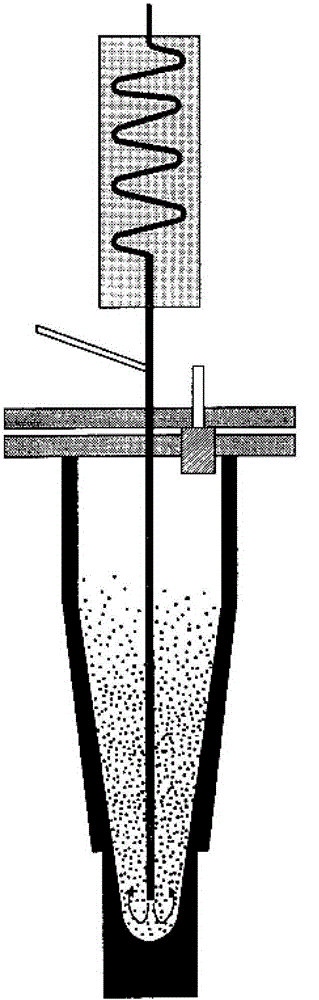

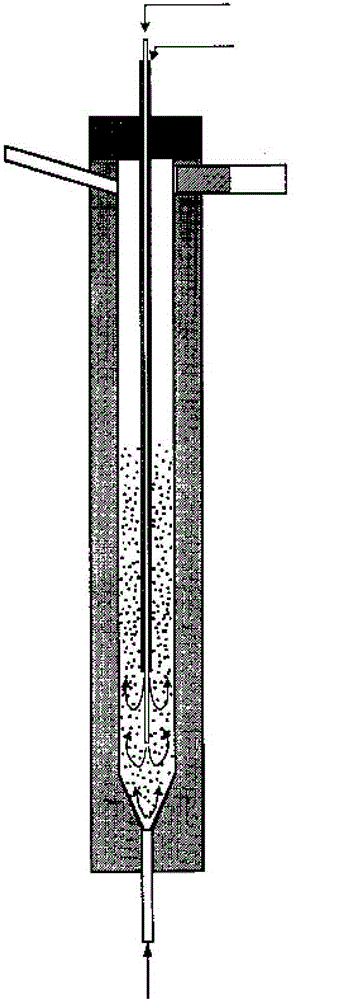

A technology of fixed fluidized bed and reactor, applied in chemical instruments and methods, cracking, catalytic cracking, etc., can solve problems such as uneven distribution of catalyst, insufficient contact of oil agent, affecting product distribution, etc., to improve product distribution, Sufficient oil contact and stable bed velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

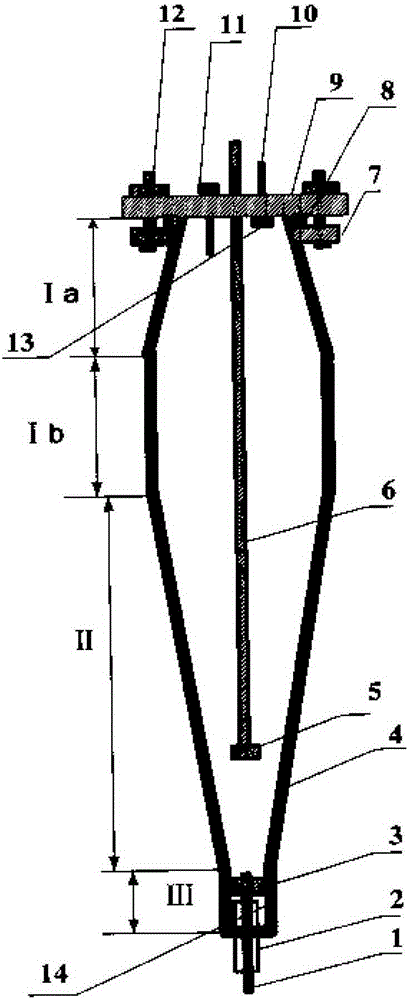

[0065] This example is used to illustrate the fixed fluidized bed reactor provided by the present invention and its application.

[0066] according to Figure 4 The reactor configuration shown is a fixed fluidized bed reactor, and the reaction section II includes the first reaction section II-1 and the second reaction section II-2 from top to bottom, and the cross-sectional area of the lower end of the settling section I is the same as The cross-sectional area of the upper end of the first reaction section II-1 is equal, the cross-sectional area of the lower end of the first reaction section II-1 is equal to the cross-sectional area of the upper end of the second reaction section II-2, and the lower end of the second reaction section II-2 The cross-sectional area is equal to the cross-sectional area of the upper end of the oil agent initial contact section III, and the cross-sectional area of the first reaction section II-1 gradually increases from top to bottom, a...

Embodiment 2

[0086] This example is used to illustrate the fixed fluidized bed reactor provided by the present invention and its application.

[0087] According to the method of embodiment 1, adopt the fixed fluidized bed reactor described in this embodiment, the straight-run naphtha whose raw material properties are as shown in table 1 is catalyzed under the effect of catalyst properties as shown in table 2 Cracking reaction, and analysis of reaction products, operating conditions and product analysis results are shown in Table 4.

[0088] The difference is that the size parameters of each section of the fixed fluidized bed reactor used in this example are different, and the first reaction section II-1 and the second reaction section II-2 of the fixed fluidized bed reactor used in this example are both It is in the shape of a truncated cone, wherein the angle α of the first reaction section II-1 of the truncated shape is 41°; the angle β of the second reaction section II-2 of the truncate...

Embodiment 3

[0099] This example is used to illustrate the fixed fluidized bed reactor provided by the present invention and its application.

[0100] According to the method of embodiment 1, adopt the fixed fluidized bed reactor described in embodiment 1 to carry out catalytic cracking under the effect of the catalyzer of catalyst property as shown in table 2 to the straight-run naphtha whose raw material properties are as shown in table 1 Reaction, the difference is that only the cone angle and the aspect ratio of the oil agent initial contact section III are changed, the cone angle of the oil agent contact section III is 30°, and the aspect ratio of the oil agent initial contact section III is 1.87: 1, and the reaction product is analyzed, operating conditions and product analysis results are shown in Table 5.

[0101] table 5

[0102]

[0103] From the results in Table 5 above, it can be seen that under the condition that other conditions remain unchanged, only the cone angle of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com