Machining feeding device for engine piston pin

A technology of mechanical processing and feeding device, which is applied in the direction of metal processing, etc., can solve the problems of dirty and messy processing workshops, waste of materials, and easy scattering of materials, etc., and achieve the effect of overall beauty, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

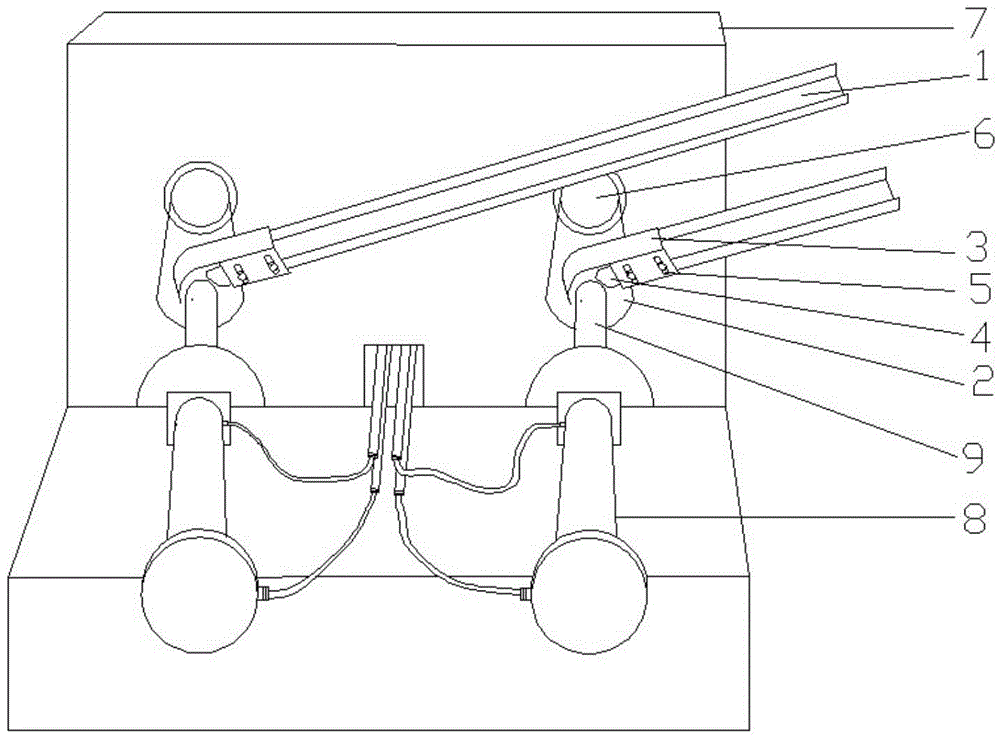

[0014] Such as figure 1 , a mechanical processing feed device for engine piston pins, comprising a feed trough 1, a feed pallet 2, a cover plate 3, and a side baffle 4, and the feed chute 1 is obliquely fixed on the side of a vertically placed processing machine 7 , and extend to the feed port 6, the feed pallet 2 is U-shaped curved, fixed below the feed port 6 and the feed tank 1, the cover plate 3 side is provided with two strip-shaped square The hole 5 is fixed on the feed tank 1 by screws, and is located above the feed tank 1 and the feed pallet 2 as a whole. The side baffle 4 is welded on the outward side of the cover plate 3 .

[0015] Working method: as figure 1 As shown, the material slides freely through the inclined feeding trough 1. There are two elongated square holes 5 on one side of the cover plate 3, which are fixed on the feeding trough 1 by screws, so that the speed of the fed material can be adjusted. The cover plate 3 3 is provided with a side baffle 4 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com