Method for measuring reel diameter and thickness of yarns on reel of air-covered yarn machine

A technology of air bag and reel, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., and can solve the problem of low precision of spindle speed control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

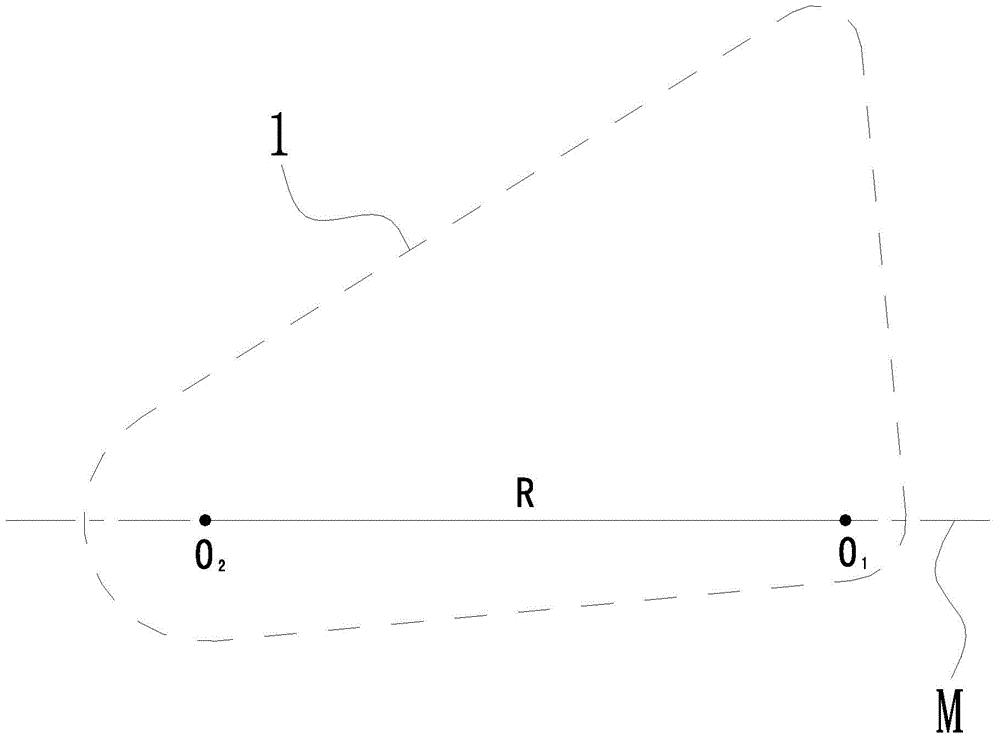

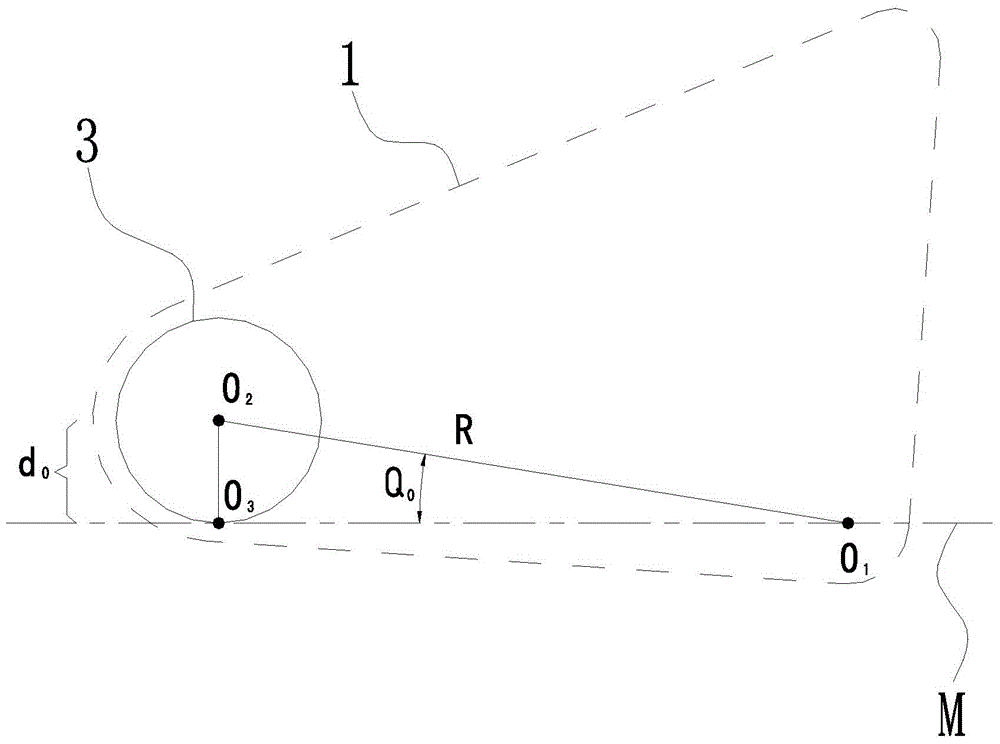

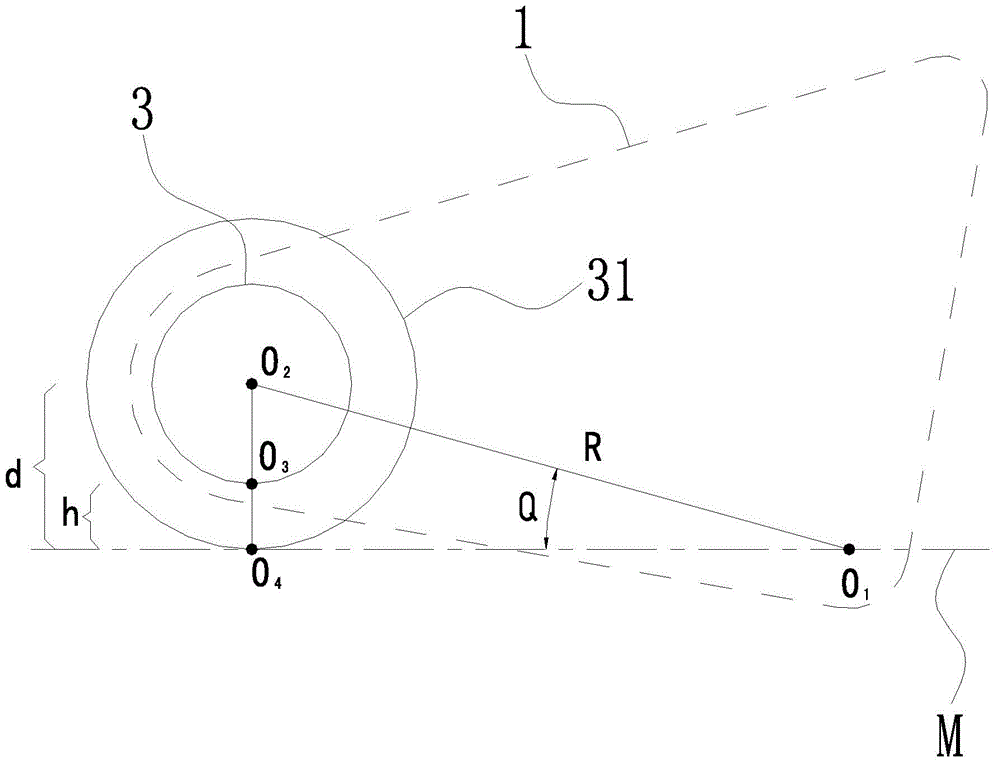

[0054] Such as Figure 4 to Figure 14 As shown, the winding system includes: a base;

[0055] Turntable 1, one end of which is rotatably mounted on the base; contact rod 2, rotatably mounted on the base;

[0056] The reel 3 for winding up the yarn is rotatably installed on the other end of the turntable 1, and the reel 3 is supported on the contact roller 2. When the yarn is rewound, the contact roller 2 passes through The yarn on the drum 3 lifts the drum 3 and drives the turntable 1 to rotate;

[0057] The winding motor 4 is installed on the turret 1, a transmission mechanism is arranged between the winding motor 4 and the reel 3, and the winding motor 4 drives the reel 3 to rotate through the transmission mechanism; the winding motor 4 can be a brushless DC servo Motor, high control precision;

[0058] A rotation angle measuring device 5 for measuring the rotation angle of the turntable 1 is arranged between the base and the turntable 1;

[0059] The controller (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com