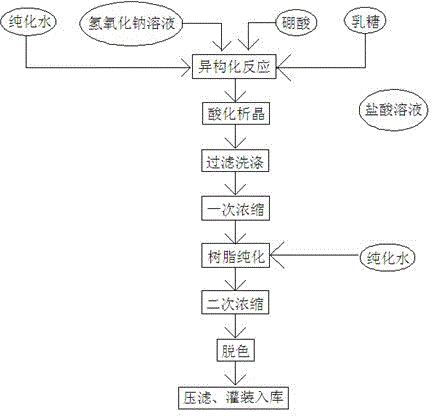

Production process of concentrated solution of lactulose

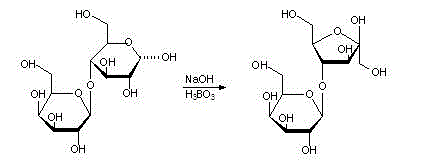

A production process and lactulose technology are applied in the production process field of lactulose concentrated solution, can solve the problems of unsuitable lactulose preparation, low lactulose yield, difficult disposal of three wastes and the like, and achieve convenient operation, high output and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0026] see figure 1 , the embodiment of the present invention includes:

[0027] Preparation of lactulose solution:

[0028] (1) Cleaning, sterilization and inspection of reaction equipment and workplaces;

[0029] Before the start of production, check that there are no products, documents or materials unrelated to the production of this batch of products left over from the previous batch in the equipment and workplace, and the equipment is in a cleaned and ready-to-use state. The operator checks and confirms that the salt-forming reaction tank is intact; confirms that the pipelines and valves of the material delivery are intact; checks and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com