3D printing material

A 3D printing and raw material technology, applied in the field of solid materials and support materials, 3D printing materials, to achieve the effect of good surface finish, simple manufacturing method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

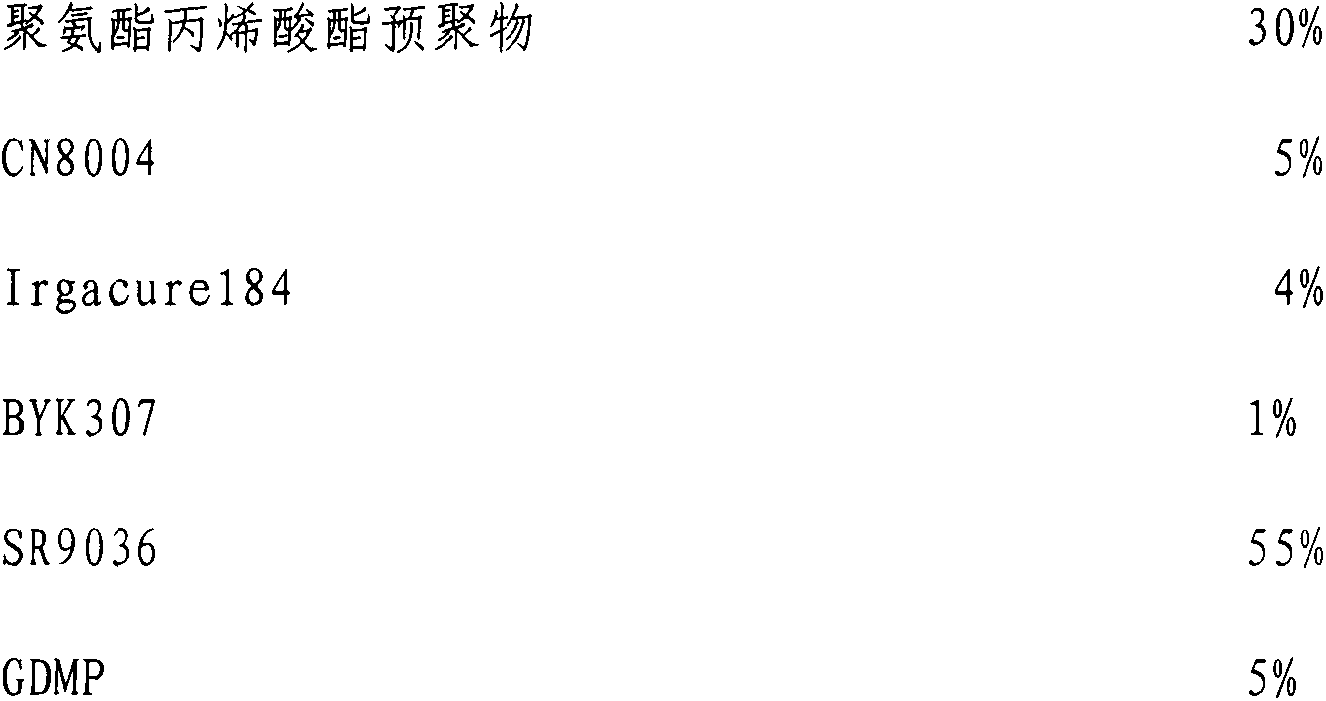

[0010] One, according to the following composition ratio (mass percentage):

[0011]

[0012] 2. Preparation method

[0013] The steps to prepare this material are: firstly stir and mix the liquid components in the technical formula components in a vacuum mixer, then add the solid components in the components and stir them evenly in the reaction kettle, and then grind them on the grinder to reach 1 micron Below, the final packaging.

Embodiment 2

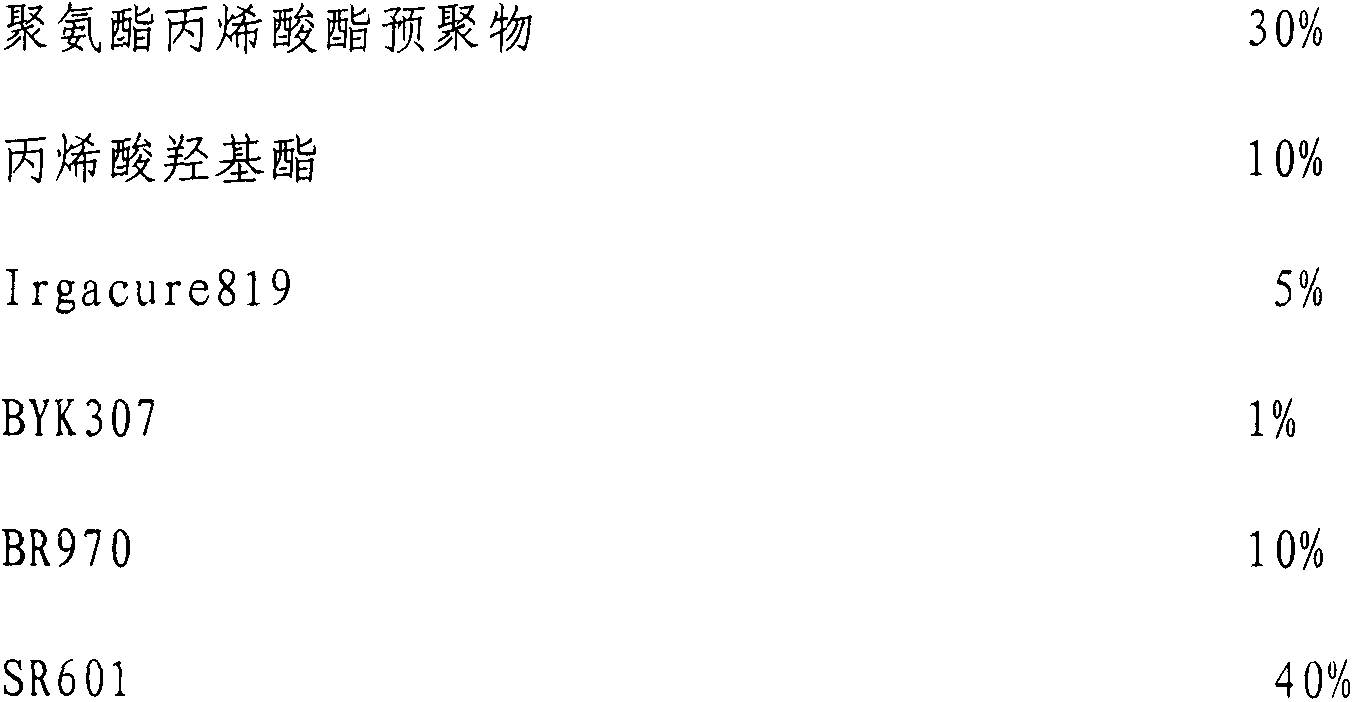

[0015] One, according to the following composition ratio (mass percentage):

[0016]

[0017]

[0018] Two, preparation method is with embodiment 1.

Embodiment 3

[0020] One, according to the following composition ratio (mass percentage):

[0021]

[0022] Two, preparation method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com