Electrolytic solution for tungsten helix electropolishing and method for tungsten helix electropolishing

An electrolytic polishing and helical technology, applied in the field of electrolyte, can solve the problems of poor heat dissipation of traveling wave tubes, affecting the performance of traveling wave tubes, complex composition of electrolyte, etc., and achieve improved smoothness, strong heat dissipation performance, and polishing precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

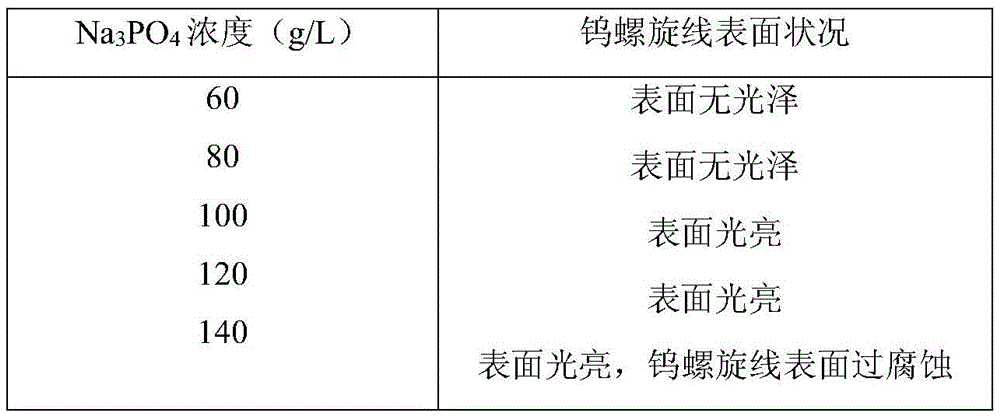

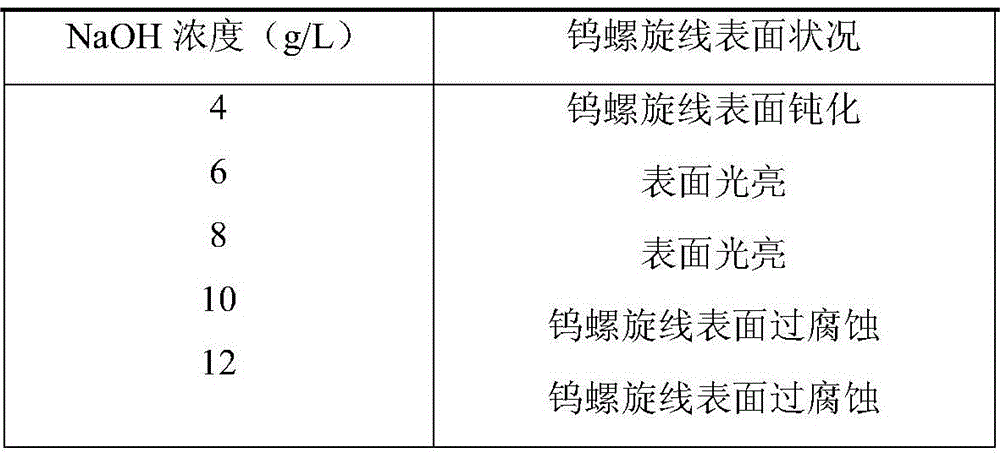

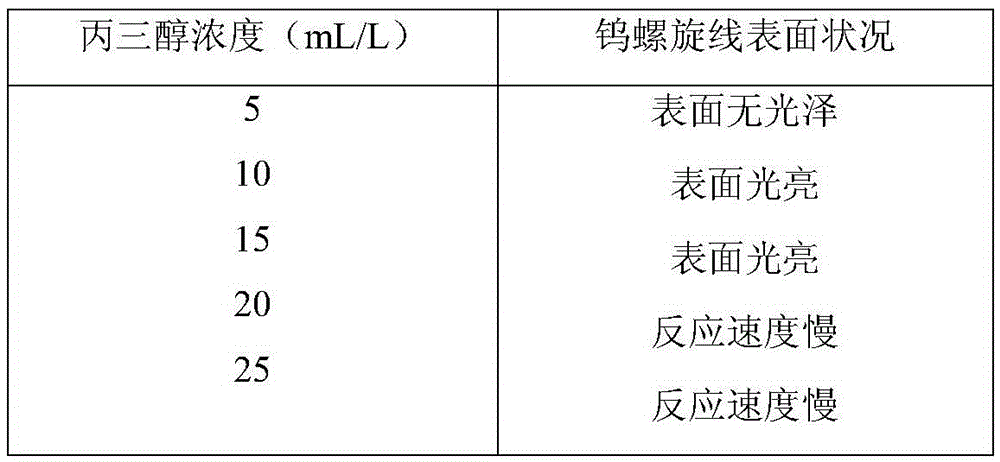

[0060] 1. An electrolyte for tungsten helix electrolytic polishing, which is made of the following raw materials:

[0061] Na 3 PO 4 120g / L, NaOH8g / L, glycerol 15mL / L, solvent is water.

[0062] 2. A method for electrolytic polishing of a tungsten helix, comprising the following steps:

[0063] (1) Put the tungsten helix into the acetone solution for ultrasonic treatment for 10 minutes;

[0064] (2) Then immerse the tungsten helix in a 1:1 hydrochloric acid solution, and weakly etch it for 0.5-1s;

[0065] (3) Then put the tungsten helix into the concentration of 120g / LNa 3 PO 4 , 8g / LNaOH, glycerol 15mL / L mixed aqueous solution, at 70 ℃, under the condition of polishing voltage 10V, carry out electropolishing treatment for 50s;

[0066] (4) After polishing, immerse the tungsten helix in hydrochloric acid for neutralization;

[0067] (5) Then immerse in chromic acid to remove surface oxides;

[0068] (6) Dehydration and drying.

[0069] Observed under a magnifying gla...

Embodiment 2

[0071] 1, a kind of electrolyte of described tungsten helix electrolytic polishing, it is made of following raw material:

[0072] Na 3 PO 4 100g / L, NaOH6g / L, glycerol 10mL / L, solvent is water.

[0073] 2. A method for electrolytic polishing of a tungsten helix provided by the present invention comprises the following steps:

[0074] (1) Put the tungsten helix into the acetone solution for ultrasonic treatment for 15 minutes; this step can remove the residual oil, dust and other dirt on the surface.

[0075] (2) Then immerse the tungsten helix in a 1:1 hydrochloric acid solution, and weakly etch it for 0.5-1s;

[0076] (3) Then put the tungsten helix into the concentration of 100g / LNa 3 PO 4 , in a mixed aqueous solution of 6g / LNaOH and 10mL / L glycerin, at 50°C and a polishing voltage of 7V, perform electrolytic polishing for 30s;

[0077] (4) After polishing, immerse the tungsten helix in hydrochloric acid for neutralization;

[0078] (5) Then immerse in chromic acid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com