Covered top-down excavation subway station overlapped wall construction method and movable side wall formwork jumbo

A technology of reverse operation of subway stations and cover-excavation, which is applied to artificial islands, water conservancy projects, infrastructure projects, etc. It can solve problems such as time-consuming, affect the progress of the project, and fail to play a role, so as to achieve simple and convenient operation and improve construction quality , Construction quality and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

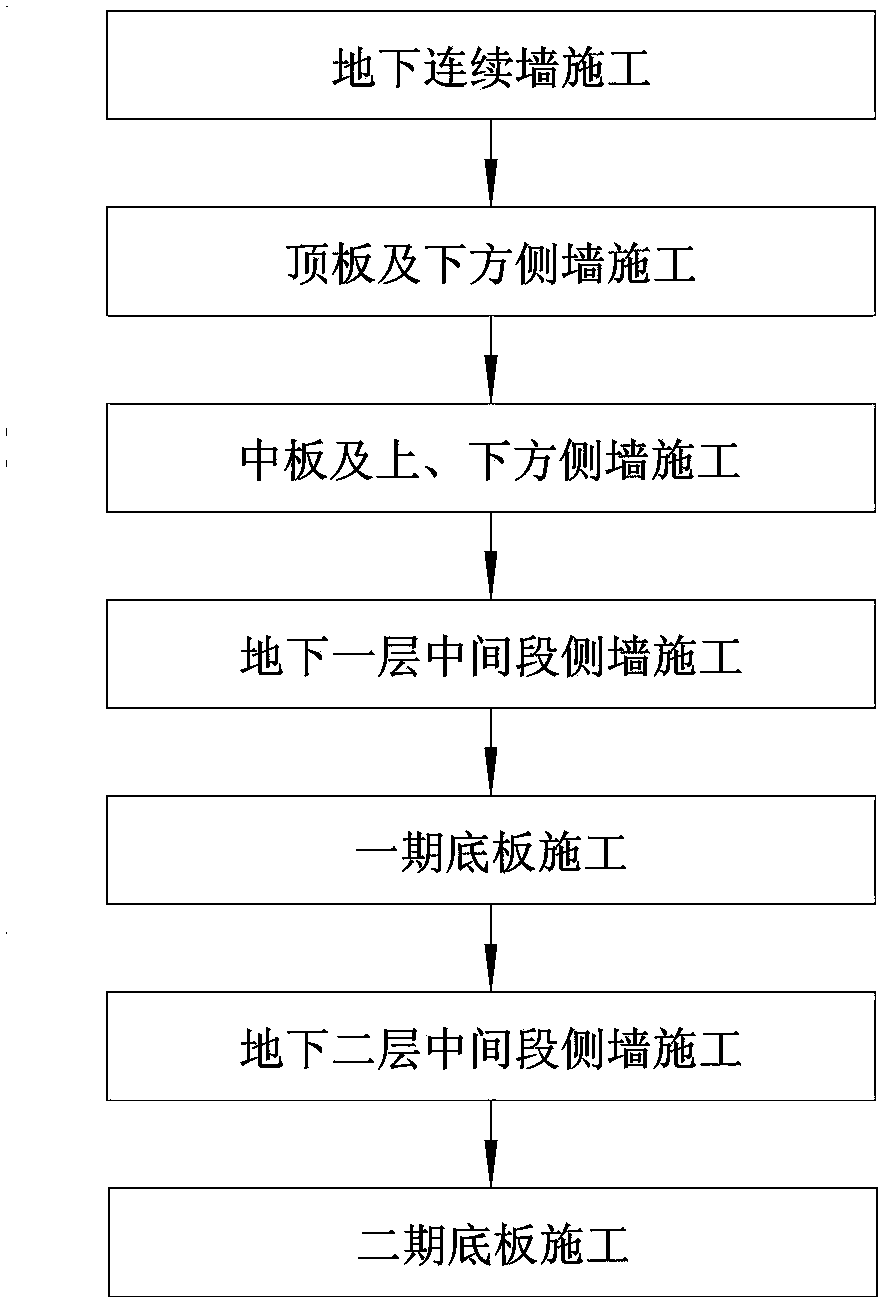

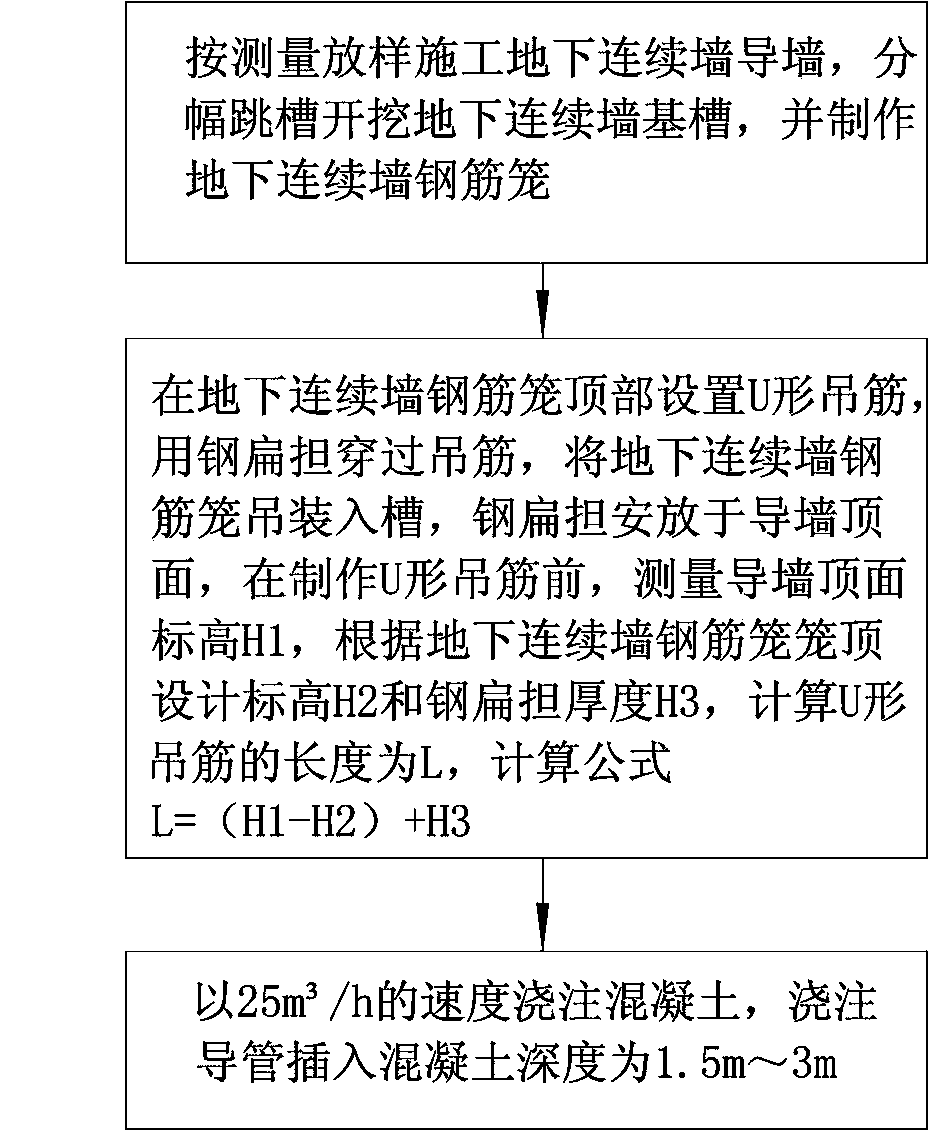

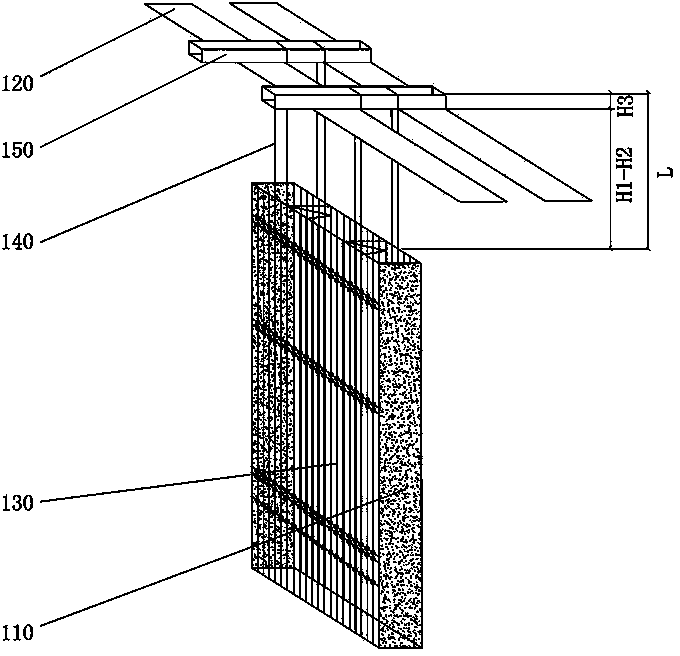

[0040] Figure 1 to Figure 4 An embodiment of the construction method for the superposed wall of a subway station with cover-cut and top-down construction of the present invention is shown. The construction method of the superposed wall of a subway station with a cover-cut and top-down construction of the present embodiment includes a pair of underground continuous walls 100. The top plate 200, the middle plate 300, the first phase bottom plate 400 and the second phase bottom plate 500 between a pair of underground continuous walls 100, and the side walls 600 arranged along the inner side of a pair of underground continuous walls 100, each wall and slab are as follows Steps of construction:

[0041] S1: Construction of 100 underground continuous walls;

[0042] S2: Roof 200 and side wall 610 below the roof construction: Diaphragm wall 100 chiseling and cleaning: excavation of the top slab foundation pit and 20cm side wall trench below the roof, and then chiseling the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com