Heat-insulating and sound-insulating insulation board structure in indoor large-temperature-difference area

A technology of thermal insulation board and large temperature difference, which is applied in the direction of thermal insulation, sound insulation, building components, etc., can solve pollution and other problems, achieve the effect of solving viscose pollution, reducing construction difficulty, and solving the effect of slow progress on site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

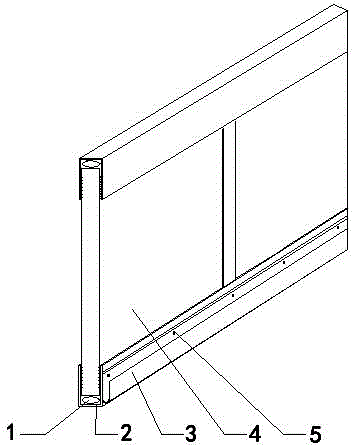

[0012] Example: such as figure 1 As shown, a heat-insulating and sound-insulating heat-insulating board structure for an indoor area with a large temperature difference, which includes a flexible heat-insulating rubber strip 1, a clip-type keel 2, a drainage groove 3, a heat-insulating and sound-insulating heat-insulating board 4, and screws 5.

[0013] The clip keel 2 is a U-shaped groove structure, and the inner surface of the U-shaped groove of the clip keel 2 is provided with latching teeth. One snap-in keel 2 is installed on the upper end of the heat insulation and sound insulation board 4, and the other snap-in keel 2 is installed on the lower end of the heat insulation and sound insulation board 4; The top surface of the building is fixed, and the clip-type keel 2 positioned at the lower end of the heat-insulation and sound-insulation insulation board 4 is fixed with the completion surface of the building.

[0014] A flexible thermal insulation rubber strip 1 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com