Energy-consumption shear wall made of composite material

A composite material, energy-consuming technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve problems affecting building functions and building design, and achieve good shock absorption effect, simple structure, good energy dissipation and shock absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

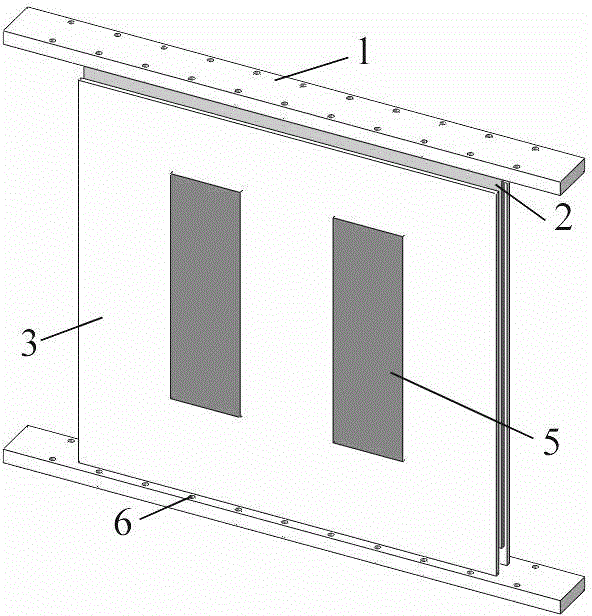

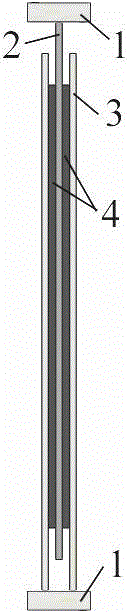

[0022] Such as figure 1 As shown, the present invention is a composite material energy-dissipating shear wall, comprising 2 upper and lower steel plates 1, 1 middle steel plate 2, 2 restraining steel plates 3, 2 viscoelastic material layers 4, and 2 sections of rectangular lead Core 5 and bolt holes 6. A rectangular hole is reserved on the middle steel plate 2 and the restraint steel plate 3, and the viscoelastic material 4 is filled between the middle steel plate 2 and the restraint steel plate 3. After the steel plates 2-3 and the viscoelastic material 4 are vulcanized together, lead is poured into the pre- The lead core 3 is solidified in the hole, and the upper and lower steel plates 1 have bolt holes 6, which can be connected with the upper and lower frame beams by bolts as an energy-dissipating shear wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com