A logic control circuit for automatic pressurization of full hydraulic long auger drilling rig

A long auger drilling rig, logic control technology, applied in the automatic control system of drilling, fluid pressure actuating device, drilling equipment, etc., can solve the problems of fragile wire rope, loose strands of pressurized hoisting wire rope, and chaotic winding of wire rope, etc. Achieve the effect of preventing scattered stocks and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but they are not used to limit the scope of the present invention.

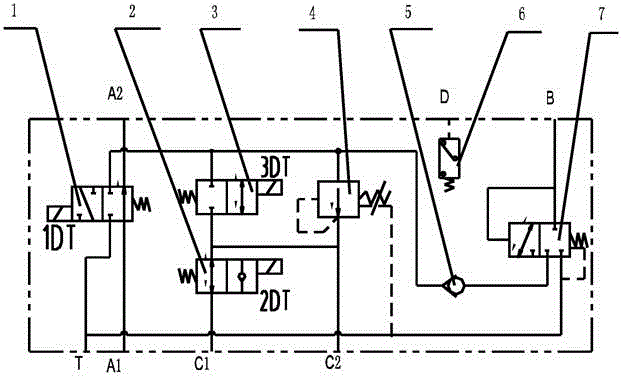

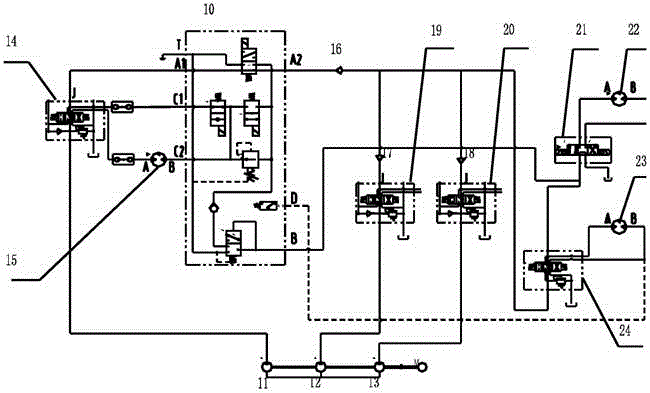

[0018] like figure 1 As shown, the automatic pressurization logic control circuit of the full hydraulic long auger drill consists of a two-position four-way electromagnetic directional valve 1, a first two-position two-way electromagnetic directional valve 2, a second two-position two-way electromagnetic directional valve 3, and Pressure valve 4, one-way valve 5, pressure relay 6, hydraulic control reversing valve 7. All components are integrated in the hydraulic valve block and connected through the oil passage inside the valve block. Specifically, the hydraulic valve block has a hydraulic oil inlet A1 and a hydraulic oil outlet A2, a power head motor working pressure test port B, a first pressurized hoist inlet C1, a second pressurized hoist inlet C2, a pressure test port D and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com