Elastic supporting device vibration strain monitoring method

A technology of vibration strain and elastic support, which is applied in the direction of vibration measurement in solids, measuring vibration, instruments, etc., can solve the problem that the squeeze oil film damper of the elastic support can not work reliably in the oil film linear region, The vibration information of the casing can not be accurately reflected and other problems, so as to achieve the effect of friendly man-machine interface, improve safe operation performance, and avoid inaccurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

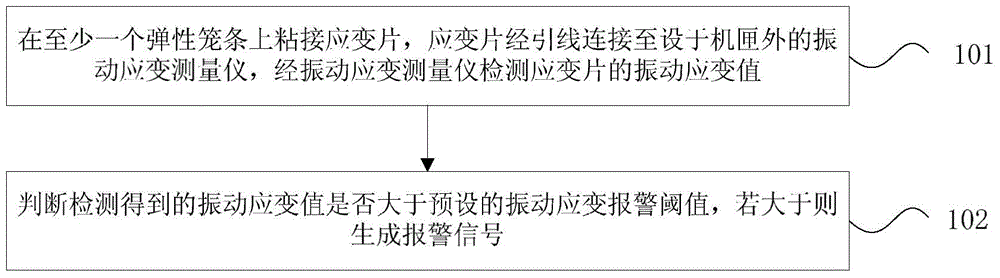

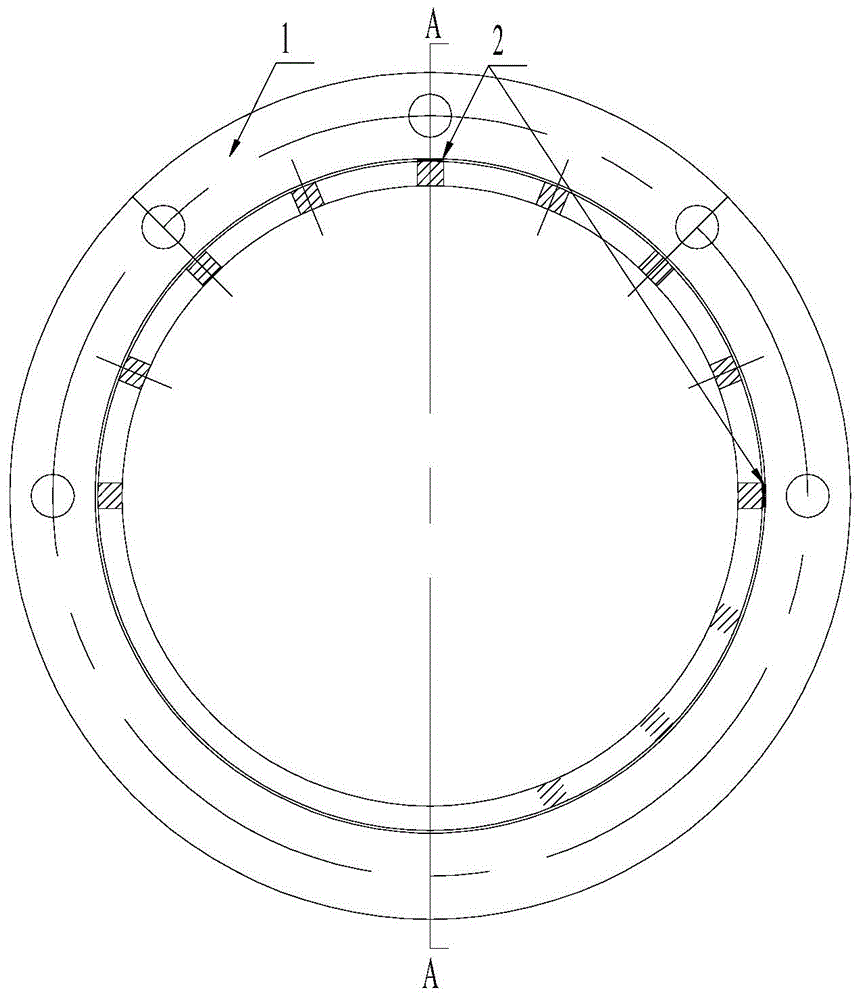

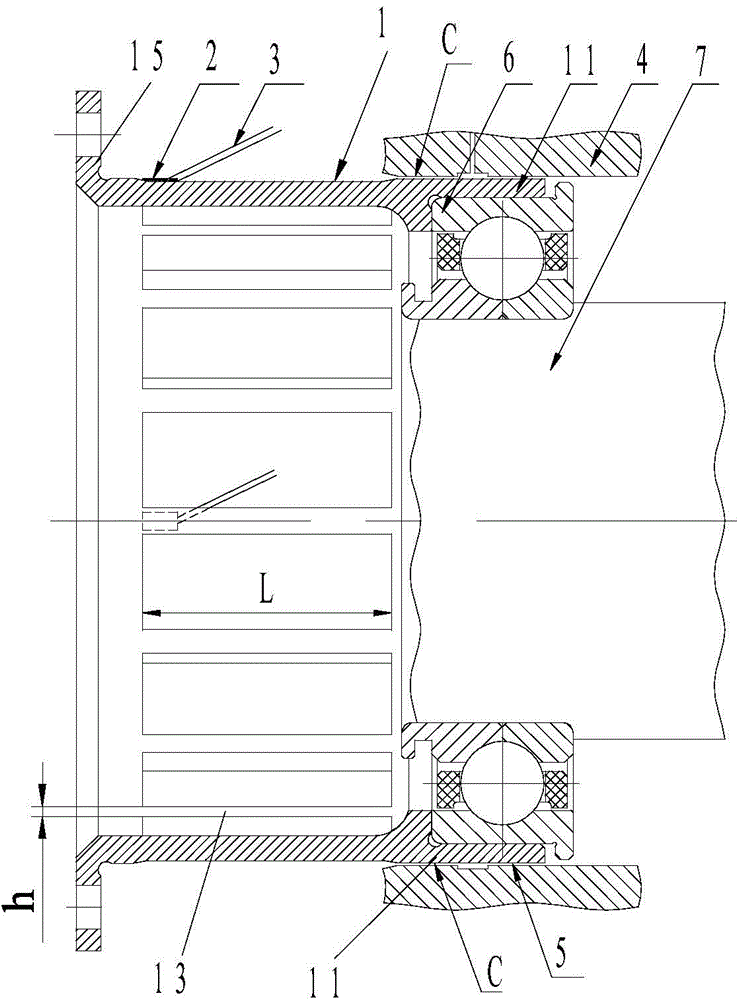

[0033] A preferred embodiment of the present invention provides a method for monitoring vibration and strain of an elastic support, referring to figure 2 and image 3 , in the embodiment of the present invention, the support body of the elastic support 1 includes a bearing seat 11 and a plurality of elastic cage bars 13 distributed along the circumference of the bearing seat 11, and the ends of the plurality of elastic cage bars 13 are along the radial direction of the support body Extending outward to form a mounting edge 15, a gap is formed between the circumferential outer wall of the bearing housing and the casing 4, and the gap is filled with lubricating oil to form the squeeze oil film damper 5; in this embodiment, the oil film of the squeeze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com