Simulation experiment method for researching relation between seepage field and temperature field of dam

A technology for simulating experiments and seepage fields, applied in thermometers, thermometers with physical/chemical changes, permeability/surface area analysis, etc. problem, to achieve the effect of improving the temperature measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

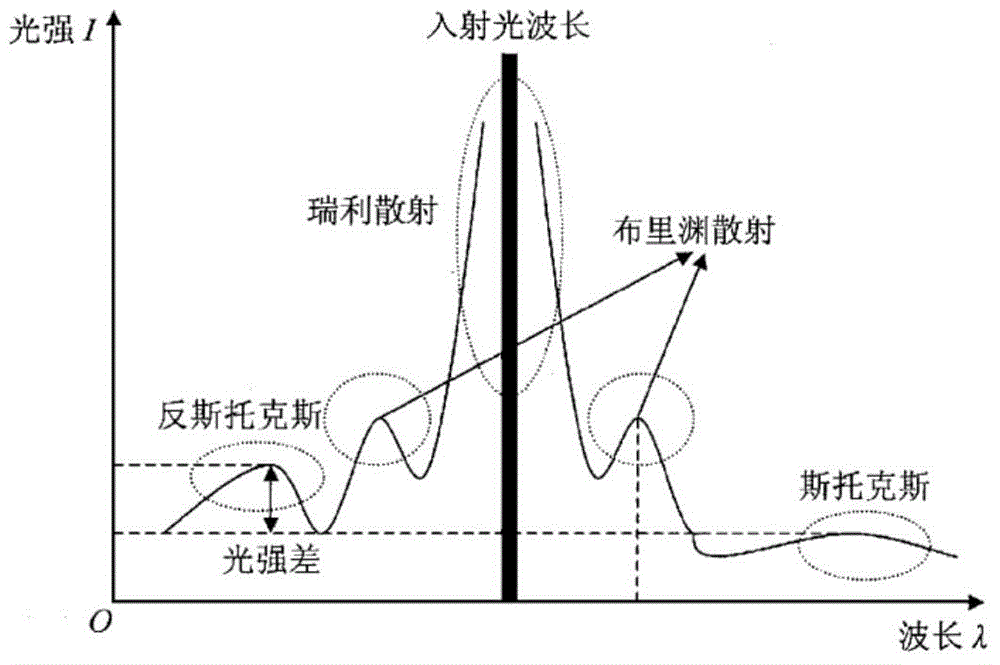

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, the simulation experiment for studying the relationship between the dam seepage field and the temperature field includes the following steps:

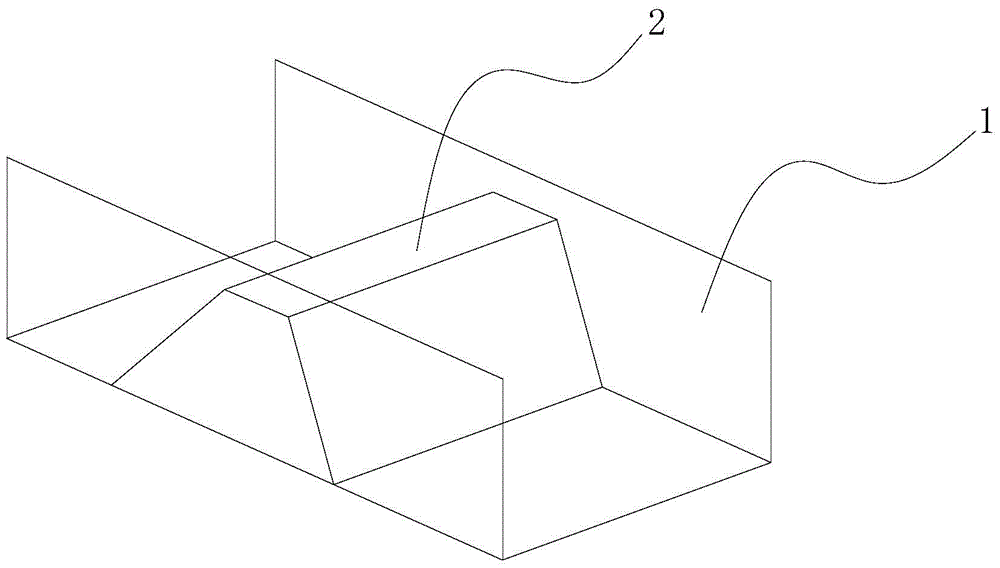

[0041]A. Build a model dam body, such as figure 2 As shown, a dam is built in a flume 1 with a head difference between the upstream and downstream and used to simulate the actual river course. The model dam body 2 is blocked between the upper and lower reaches of the water tank 1 . Both sides of the water tank 1 are plexiglass, the bottom of the water tank 1 is a steel plate, and the top is open;

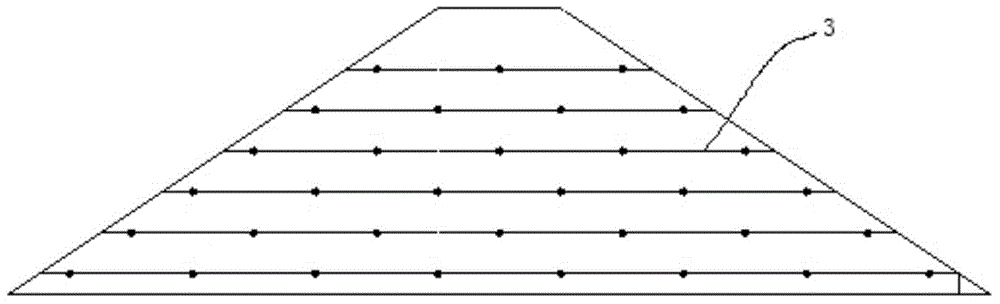

[0042] Such as image 3 As shown, when building the dam, fill the first layer of sand with a thickness of 5 cm at the preset position on the bottom plate of the tank 1, and lay the temperature-sensing optical fiber 3 in the DTS system on the first layer of sand in an S-shape. Cover the second layer of sand on the first layer of sand, and then pull the temperature-sensing optical fiber 3 to the second layer of s...

Embodiment 2

[0068] The experimental method in this embodiment is that the parameters are appropriately changed relative to the first embodiment, including the following experimental steps:

[0069] A. Build a dam on the bottom plate of the flume 1 used to simulate the actual river course. Both sides of the water tank 1 are plexiglass, the bottom of the water tank 1 is a steel plate, and the top is open. Fill the first layer of sand with a thickness of 5 cm at the preset position on the bottom plate of the water tank 1, and lay the temperature-sensing optical fiber 3 in the DTS system on the first layer of sand in an S-shape. Such as image 3 As shown, cover the second layer of sand on the first layer of sand, then pull the temperature-sensing optical fiber 3 onto the second layer of sand and lay it in the same S-shape, and build up layer by layer until the model dam body 2 is built. The temperature-sensitive optical fiber 3 is buried in 6 layers in the model dam body 2 . The material o...

Embodiment 3

[0076] Since the experimental water tank 1 is relatively narrow, in order to reduce the influence of the external temperature on the temperature measurement of the optical fiber section, it is beneficial to further draw a smooth temperature field curve, as shown in Figure 11 As shown, on the basis of the above-mentioned embodiment, the stretch length of the temperature-sensing optical fiber 3 in the temperature-measuring ring 4 in this embodiment is 3m, and the temperature-measuring ring 4 is twisted and bundled into a smooth "8" shape, "8" The curvature of any part of the font is less than 0.05mm -1 . When the optical fiber is laid, the length direction of the "8"-shaped temperature measuring ring 4 is set to be consistent with the length direction of the model dam body 2 . In addition, the average temperature of the last 1.5m of the 3m is used as the approximate temperature of the measuring point.

[0077] The transformation that can also be carried out is: the stretched ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com