Friction generator based on existing floors

A technology of friction generator and floor, applied in the direction of friction generator, etc., can solve the problems of complex production process, low practicability, large volume, etc., and achieve the effects of large area, strong charging ability and high usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described below in conjunction with embodiment. The scope of the present invention is not limited by these examples.

[0018] The following takes the floor on which people walk as an example, combined with the attached Figure 1-Figure 4 The specific steps of the frictional power generation floor provided by the invention and its preparation method are described.

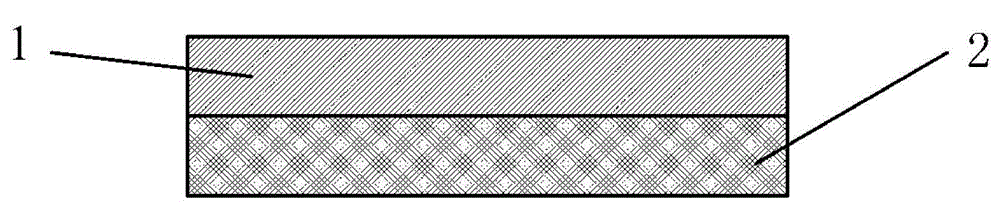

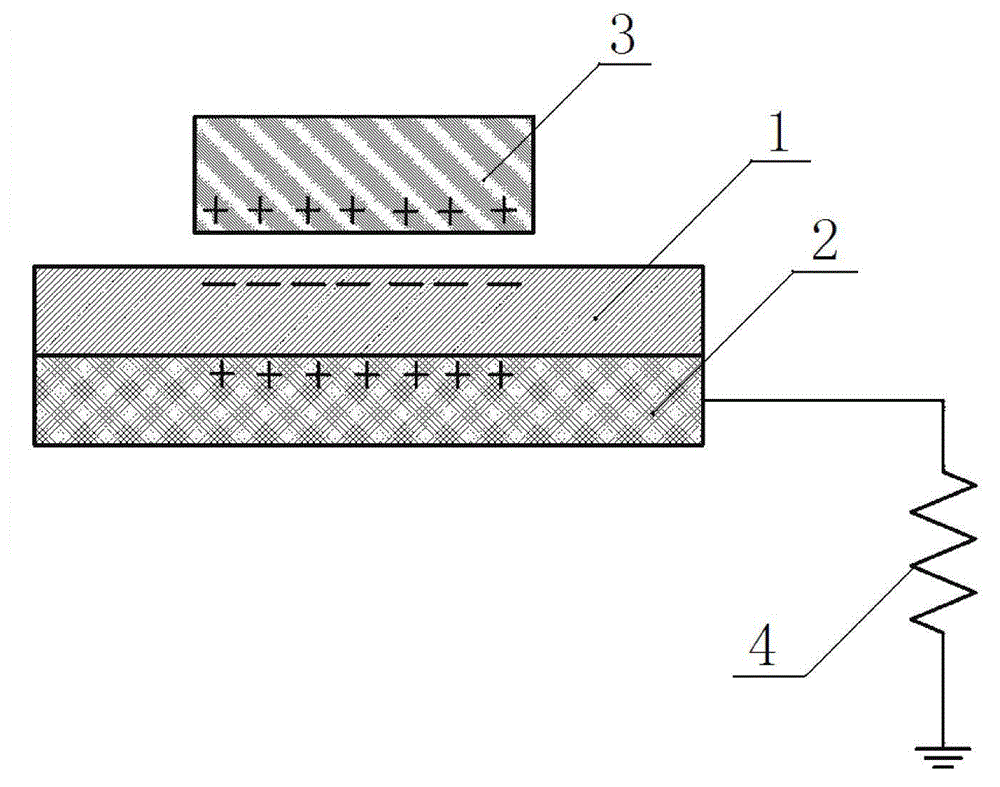

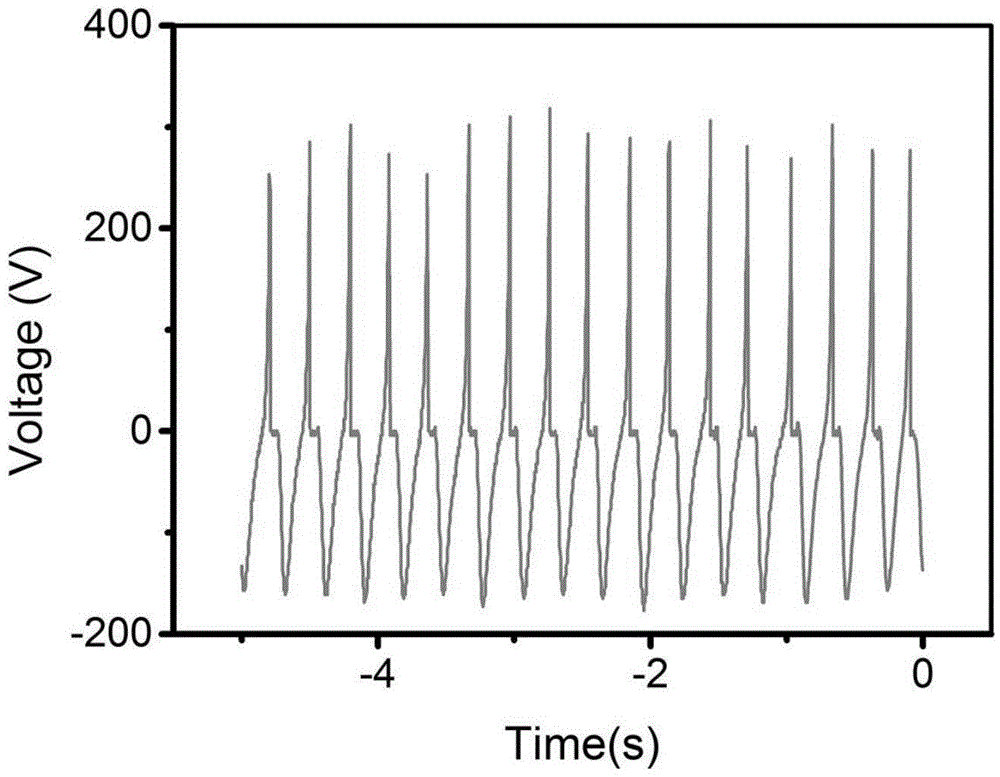

[0019] figure 1 It is a schematic diagram of the structure of the friction-type power generation floor of the present invention, and its structure includes: a common floor 1 and a conductive electrode 2 installed under the floor 1 and in contact with the floor 1 . refer to figure 2 , figure 2 It is a schematic diagram of the principle of the present invention, using figure 1 In the structure shown in , the wire drawn from the conductive electrode 2 is connected to the ground through the load 4 . When a person walks on the floor, due to the difference in the electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com