Mustard tuber harvester

A harvester and mustard technology, which is applied to harvesters, excavator harvesters, and de-roofing machines, etc., can solve the problems of incomplete initial separation and slow separation of vegetable leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

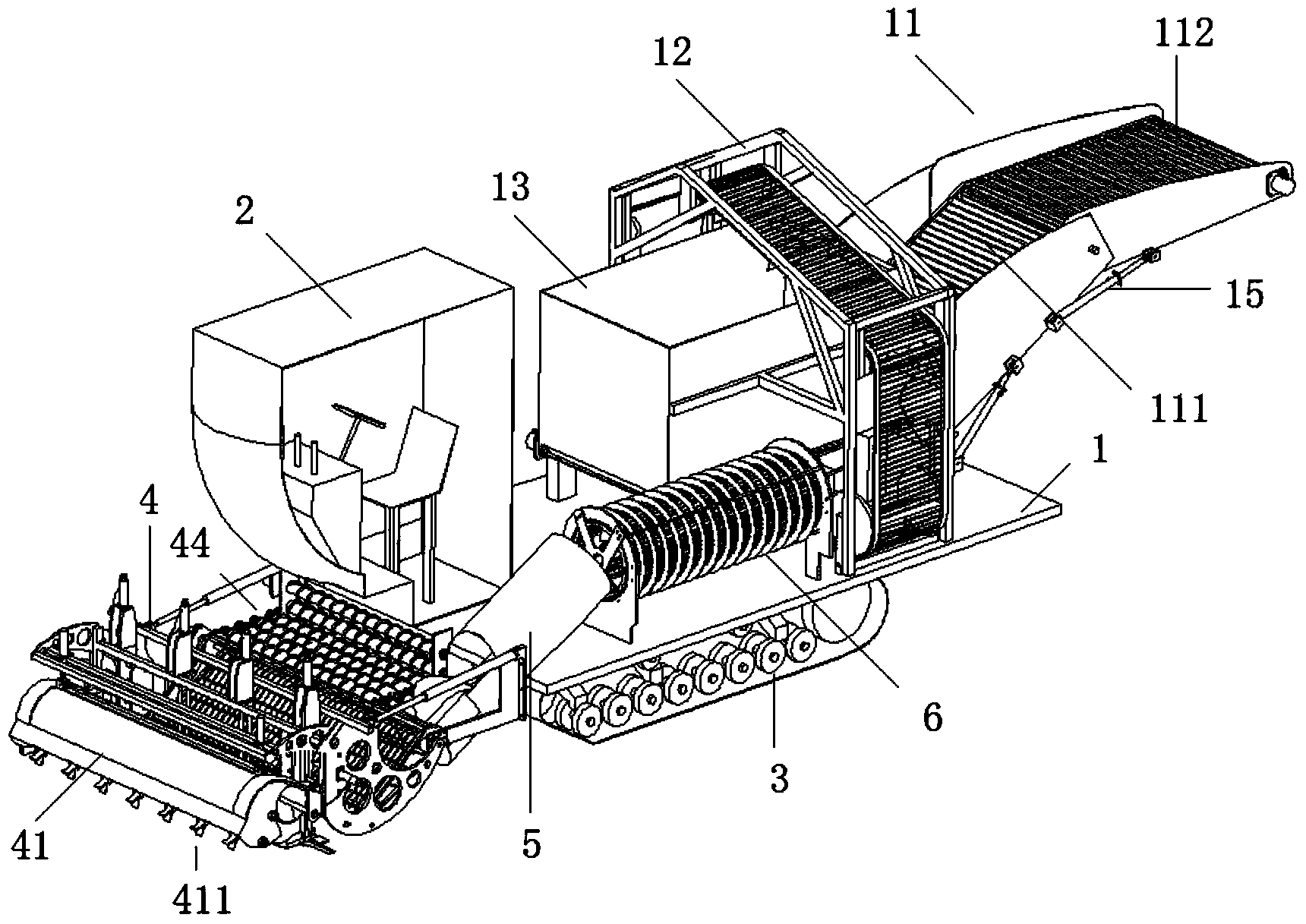

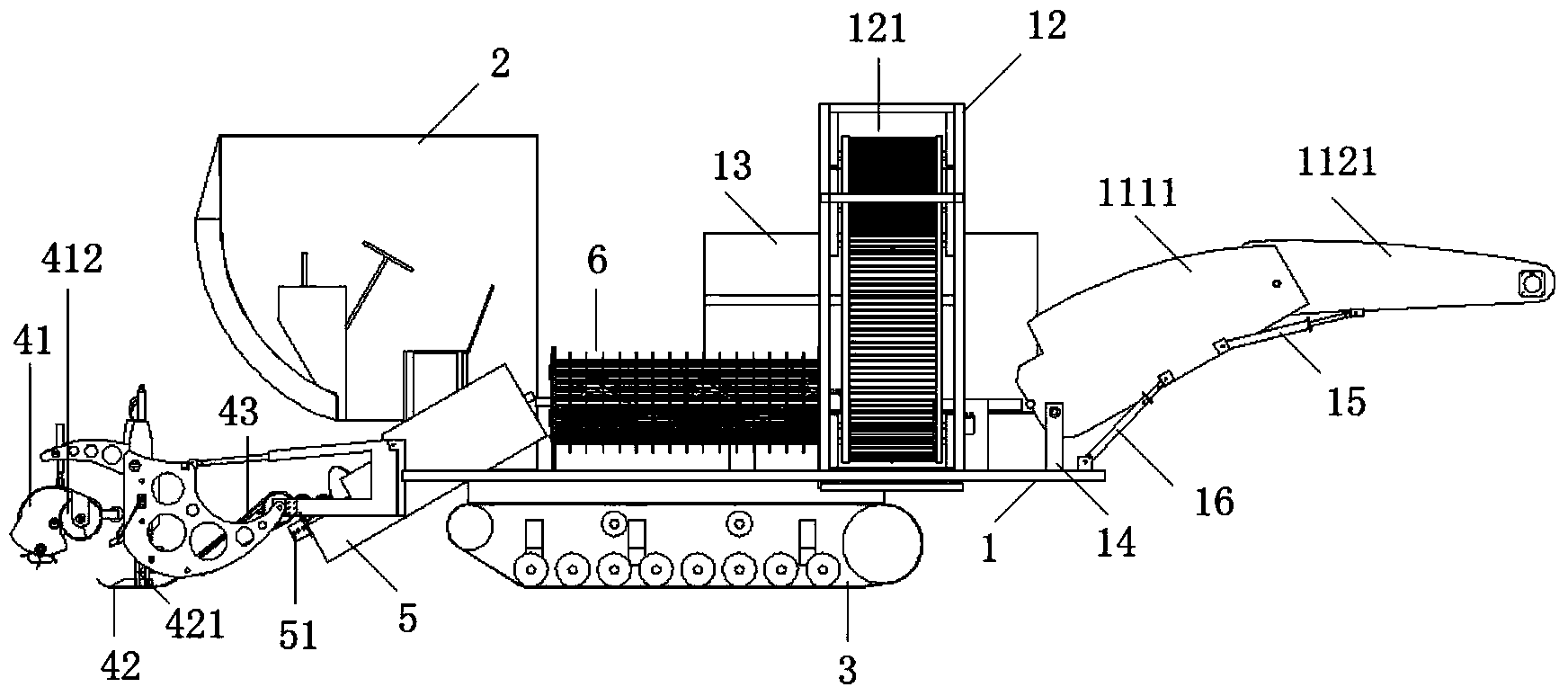

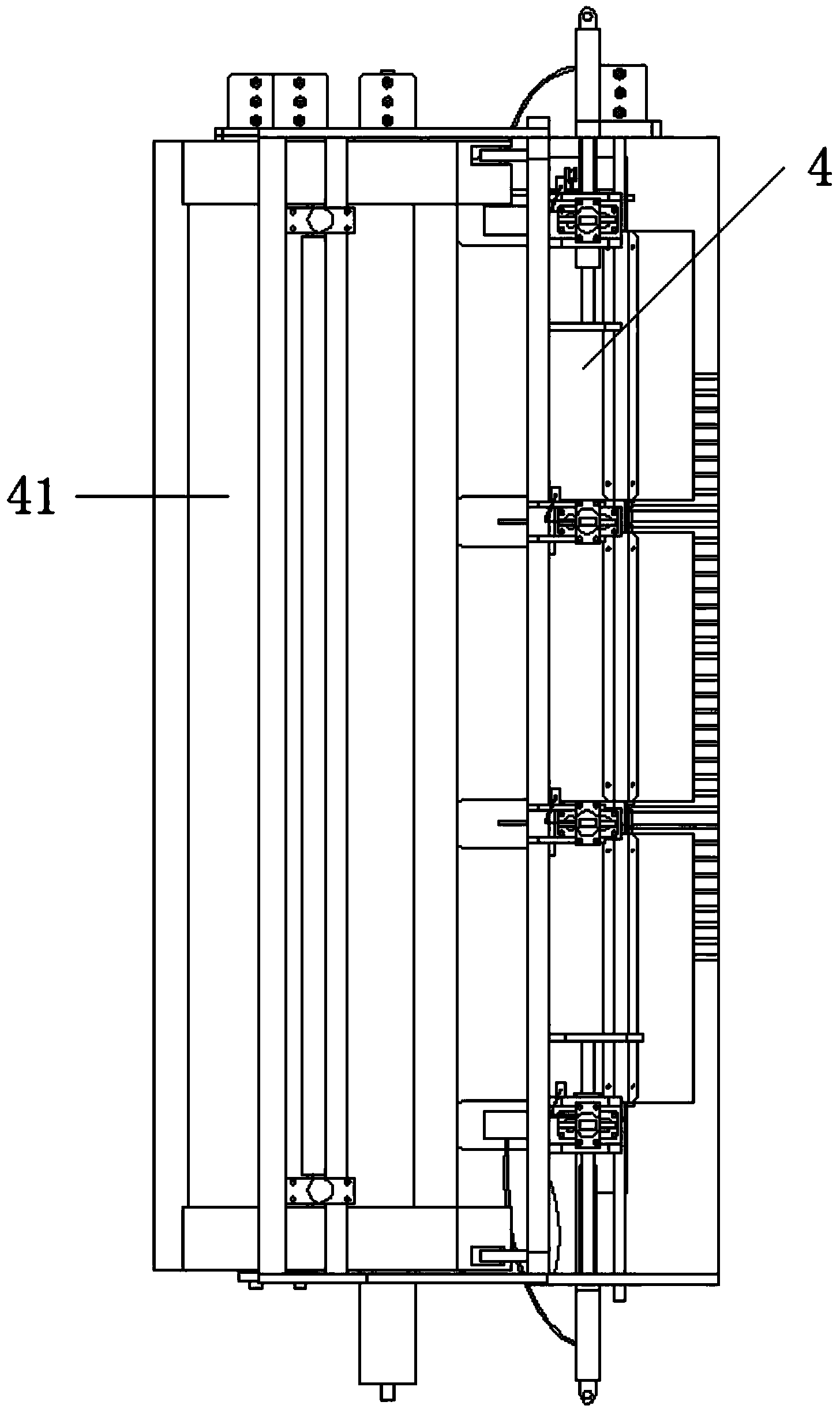

[0021] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4A mustard harvester shown includes a main body 1, a manual operation table 2, a crawler wheel 3, a power assembly with a diesel engine or other power machines, and the front end of the main body 1 is provided with a primary frame 4 , the front end of the initial collection base frame 4 is provided with a front cover 41, and the inside of the front cover 41 is provided with a leaf beating knife 411. Cutter shaft 4111, the rotating cutter shaft 4111 is provided with a number of blade beating blades 4112, the end of the blade beating blades 4112 away from the rotating blade shaft 4111 is bent to form a hook part, and the leaf beating blades 411 The rear is provided with a leaf-pushing auger 412, and the conveying terminal of the leaf-pushing auger 412 is at the side of the initial collection base frame 4, and the initial collection base frame 4 is provided with several spatulas 42, and the initial collection co...

Embodiment 2

[0023] Embodiment 2: The basic structure and implementation mode of this embodiment are the same as those of Embodiment 1, the difference being that the described shovel 42 is on the shovel frame 421, and the described shovel frame 421 slides with the initial collection base frame 4 connection, the first collection base frame 4 is provided with a lateral movement fixture for fixing the shovel frame 421, the described shovel blade 42 can move up and down along the shovel frame 421, and the described shovel frame 421 is provided with a The vertical movement fixture of frame 421. With the above-mentioned horizontal and vertical mechanical adjustment mechanism, the width between the shovels 42 and the height of the shovels 42 from the ground can be adjusted, so that the present invention can adapt to the harvesting of various sizes, heights and different varieties of pickled mustard .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com