Preparation device of hydrogenated butadiene-acrylonitrile rubber

A technology of hydrogenated nitrile rubber and preparation equipment, which is applied in the direction of chemical/physical/physical chemical fixed reactors, etc., can solve the problems that the total production capacity cannot meet the domestic market demand, and achieve simple structure, thorough reaction and short reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

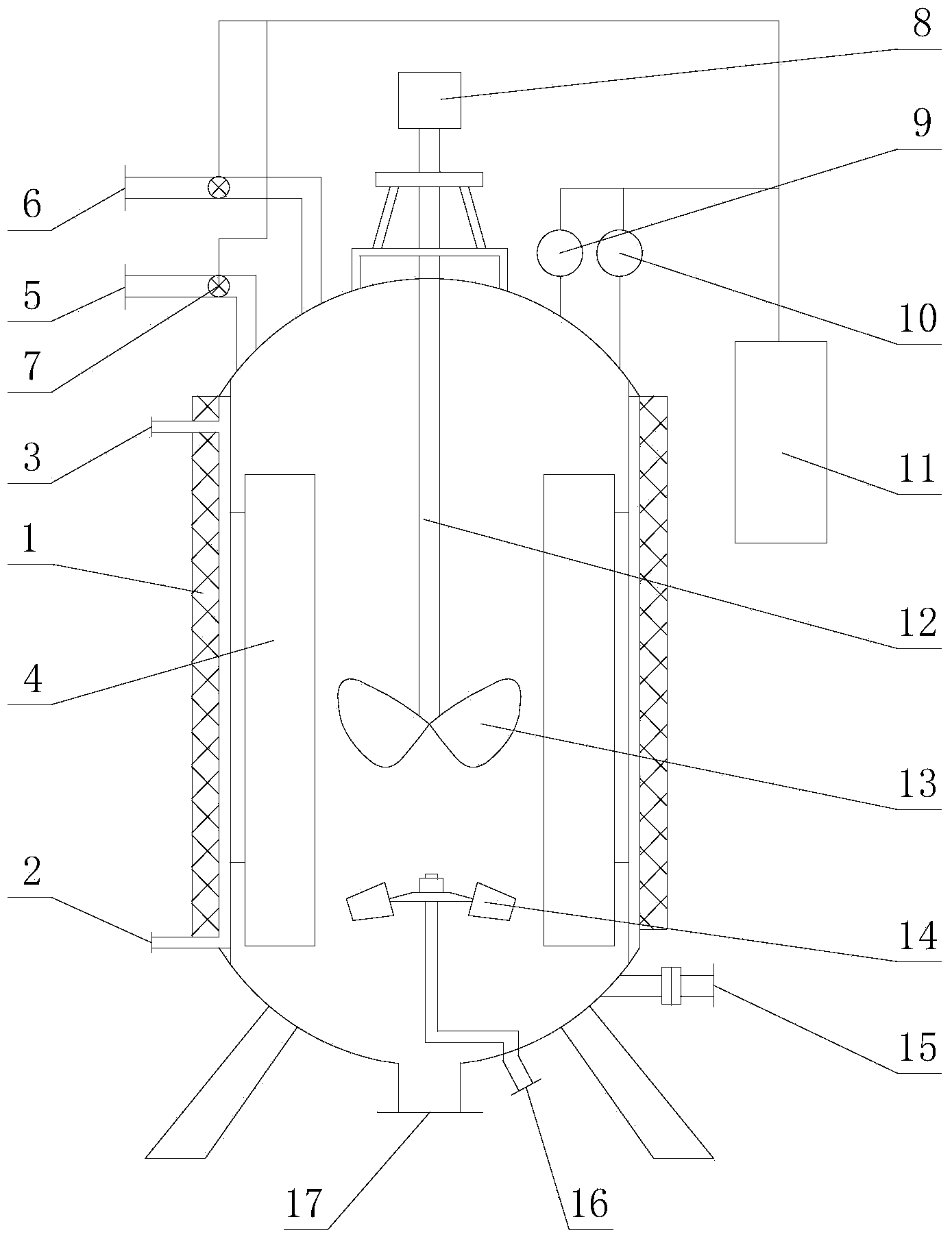

[0013] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0014] like figure 1 The preparation device of a kind of hydrogenated nitrile butadiene rubber shown has a hollow interlayer heatable cylinder and a control cabinet 11 placed on the outside of the cylinder. and the catalyst inlet 6, a stirring shaft 12 is suspended in the cylinder, one end of the stirring shaft 12 protrudes from the cylinder and is connected with the motor 8, and the other end of the stirring shaft 12 is connected with a stirring blade 13; the bottom of the cylinder is provided with a hydrogen inlet 16 and a sewage outlet 17, The hydrogen inlet 16 is connected with an aerator 14 through a pipeline; the lower half of the cylinder is provided with a discharge por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com