High-voltage static electricity fluctuating dust removal system having wind power assisted dust removal function

A high-voltage electrostatic and dust removal system technology, applied in electrostatic cleaning, photovoltaic power generation, electrical components, etc., can solve the problems of short service life, unusable, complex structure, etc., to improve dust removal efficiency, avoid distance restrictions, and adjust flexibly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

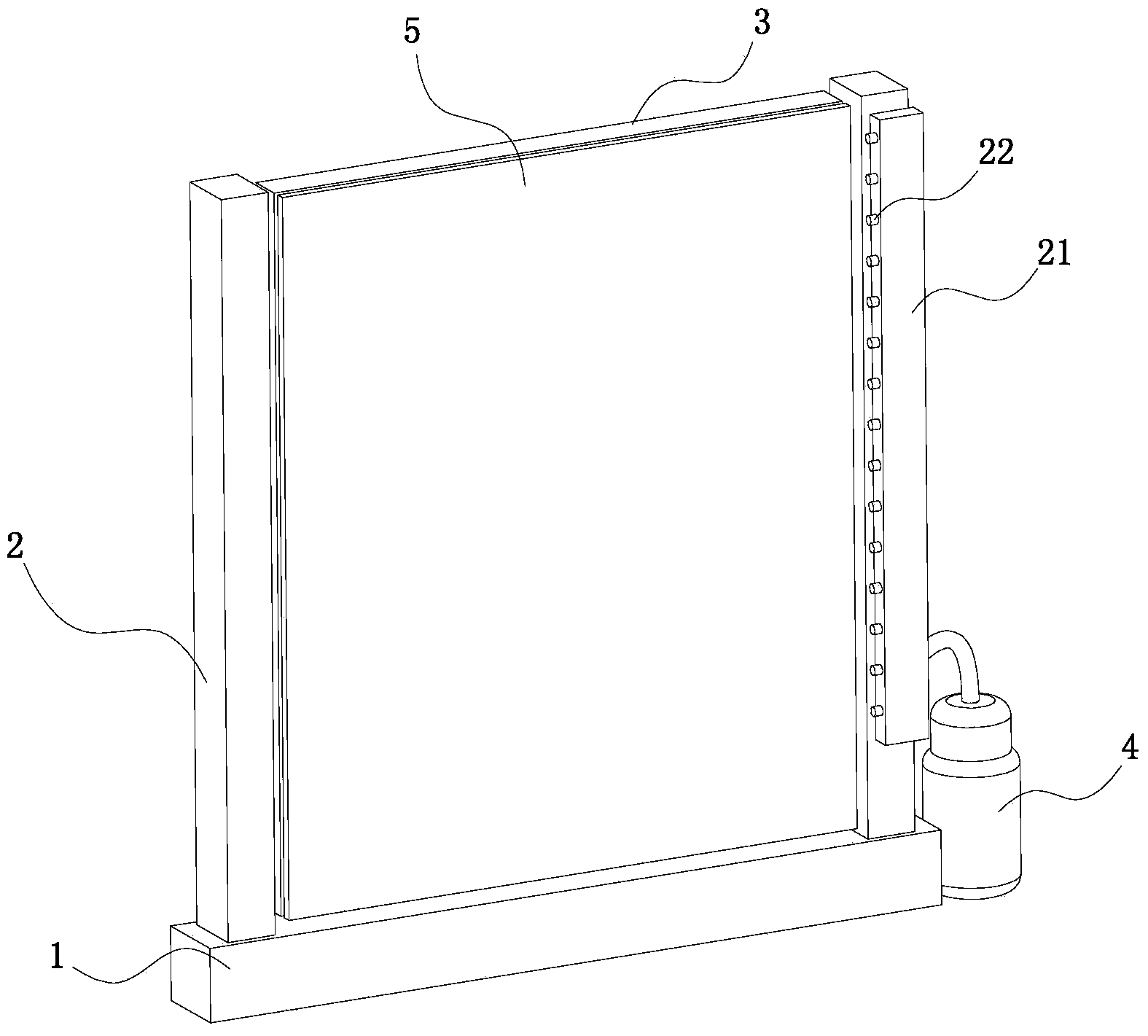

[0012] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

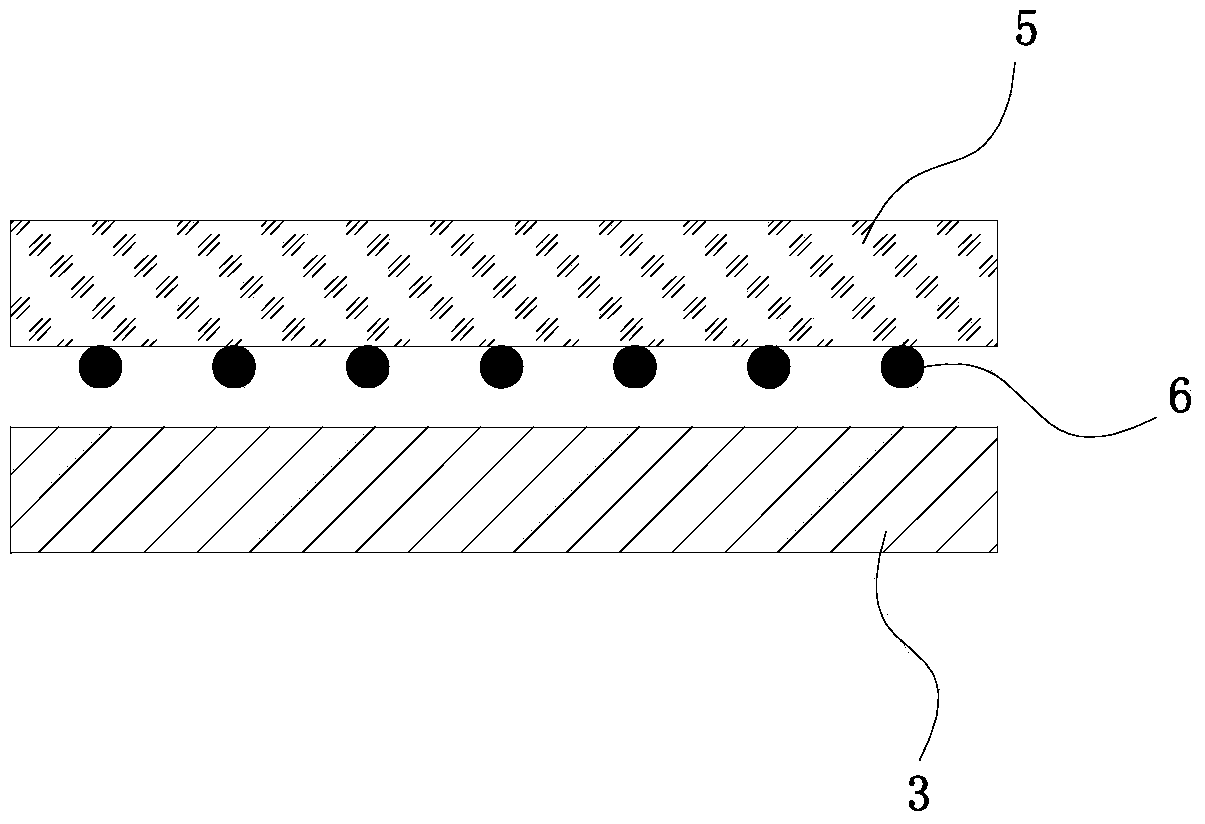

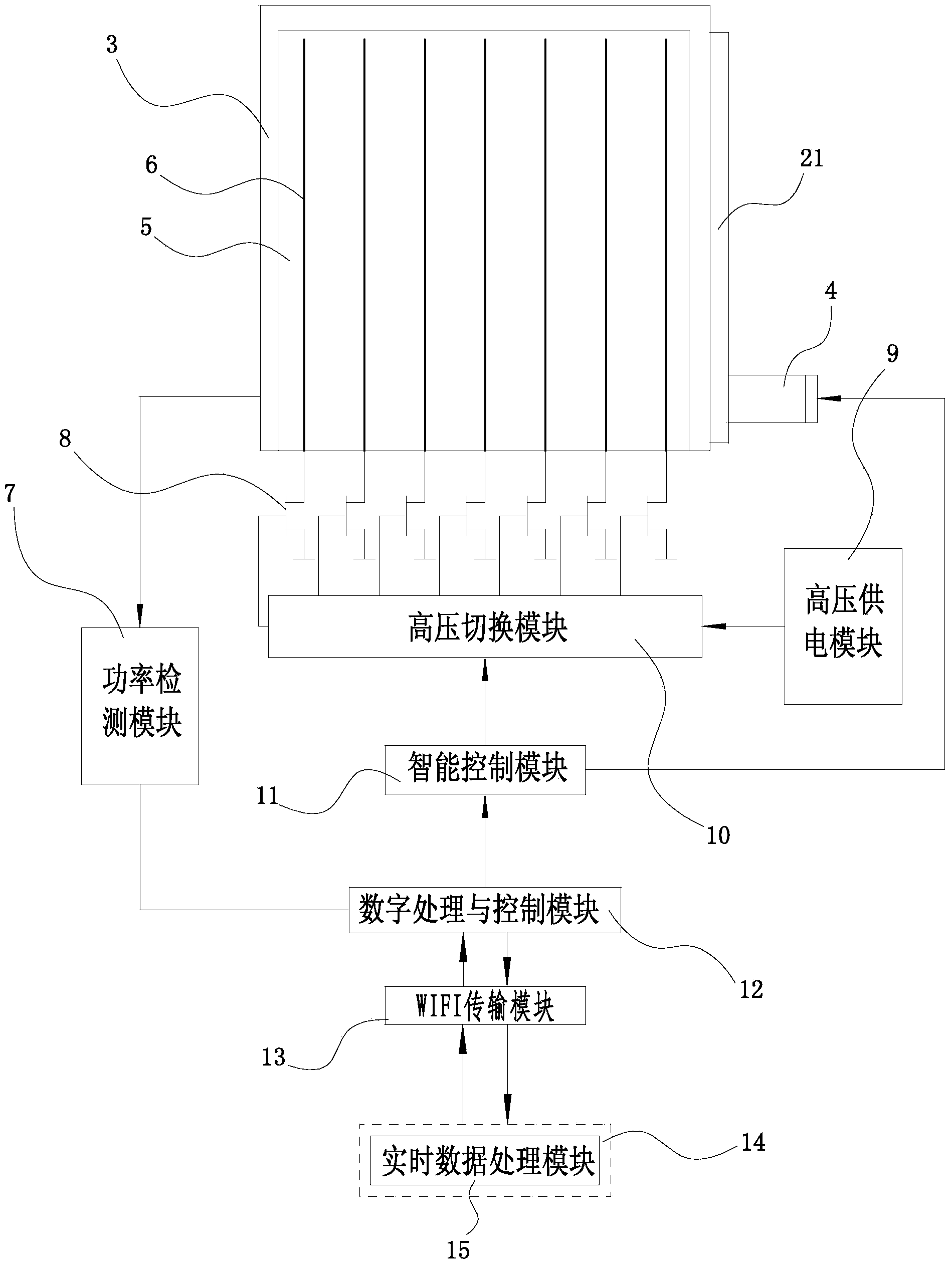

[0013] See Figure 1 to Figure 3 , the present invention comprises a base 1, the base 1 is equipped with a solar cell panel 3 by means of a support rod 2, a glass protective layer 5 is installed on the solar cell panel 3, a wind deflector 21 is installed on one side of the support rod 2, and the side of the wind deflector 21 A plurality of air ducts 22 are evenly distributed on the top, and the air guide plate 21 is connected to the fan 4; the lower surface of the glass protective layer 5 is equipped with a plurality of parallel electrodes 6, and the ends of the electrodes 6 are connected to the high voltage switch 8 and the high voltage switch 8 respectively. Electrically connected to the high-voltage switching module 10, the high-voltage switching module 10 is powered by the high-voltage power supply module 9, the high-voltage switching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com