On-line Measurement Method of Axisymmetric Optical Aspherical Surface

A measurement method and aspheric surface technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of low measurement accuracy, repositioning of workpieces, and high cost, so as to improve processing accuracy and save measurement Time, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

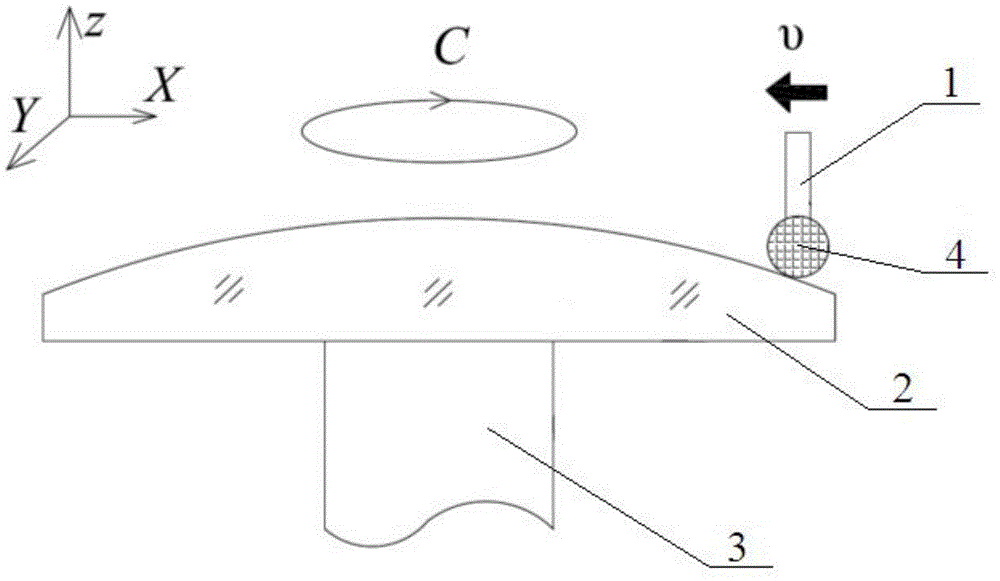

[0026] Such as figure 1 As shown, the element to be measured 2 is an axisymmetric optical aspheric element, the element to be measured 2 is fixedly mounted on the workpiece shaft 3, the element to be measured 2 can rotate along the motion axis C along with the workpiece shaft 3, and the online height gauge 1 is integrated In the CNC machining center, during measurement, the online altimeter 1 is located on the edge of the aspheric surface of the component to be measured 2 , and the measuring head 4 of the altimeter is in contact with the aspheric surface of the component to be measured 2 .

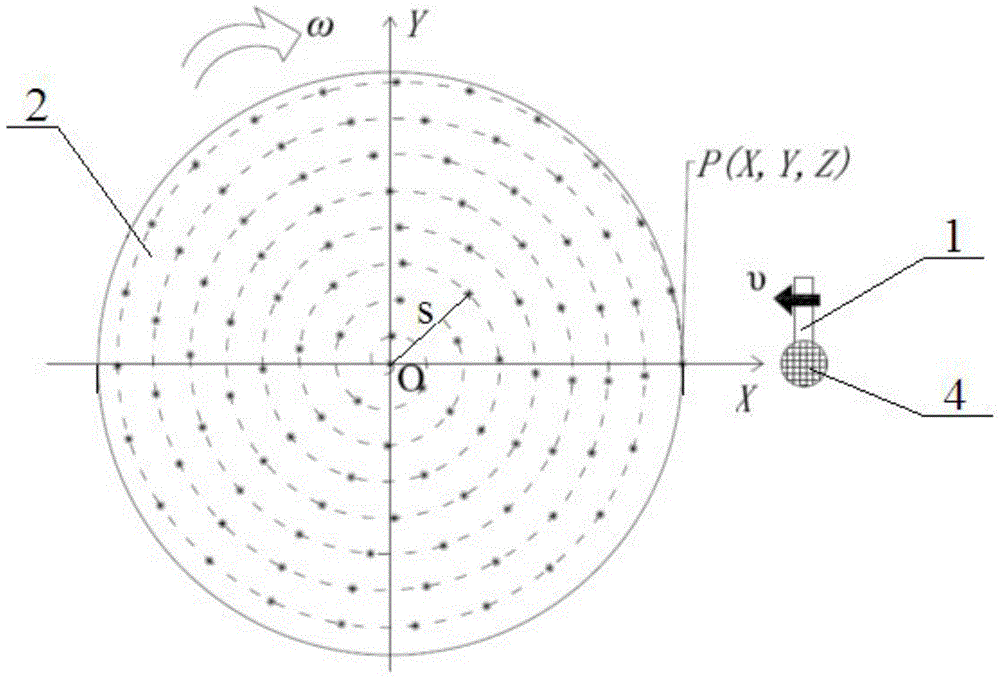

[0027] Such as figure 2 Shown, the axisymmetric optical aspheric surface shape online measuring method of the present invention, this method is realized by the following steps:

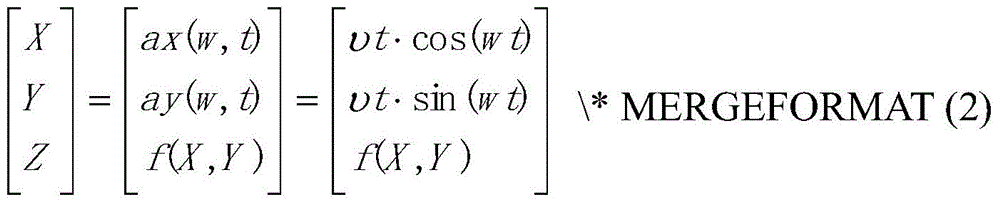

[0028] Step 1. Input the axisymmetric optical aspheric surface shape equation into the CNC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com