Electric hammer dust blower

A technology of dust blower and electric hammer, which is applied in the direction of striking tools, light impact tools, manufacturing tools, etc., and can solve the problems of high manufacturing cost, poor filtering effect of filters, dust pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

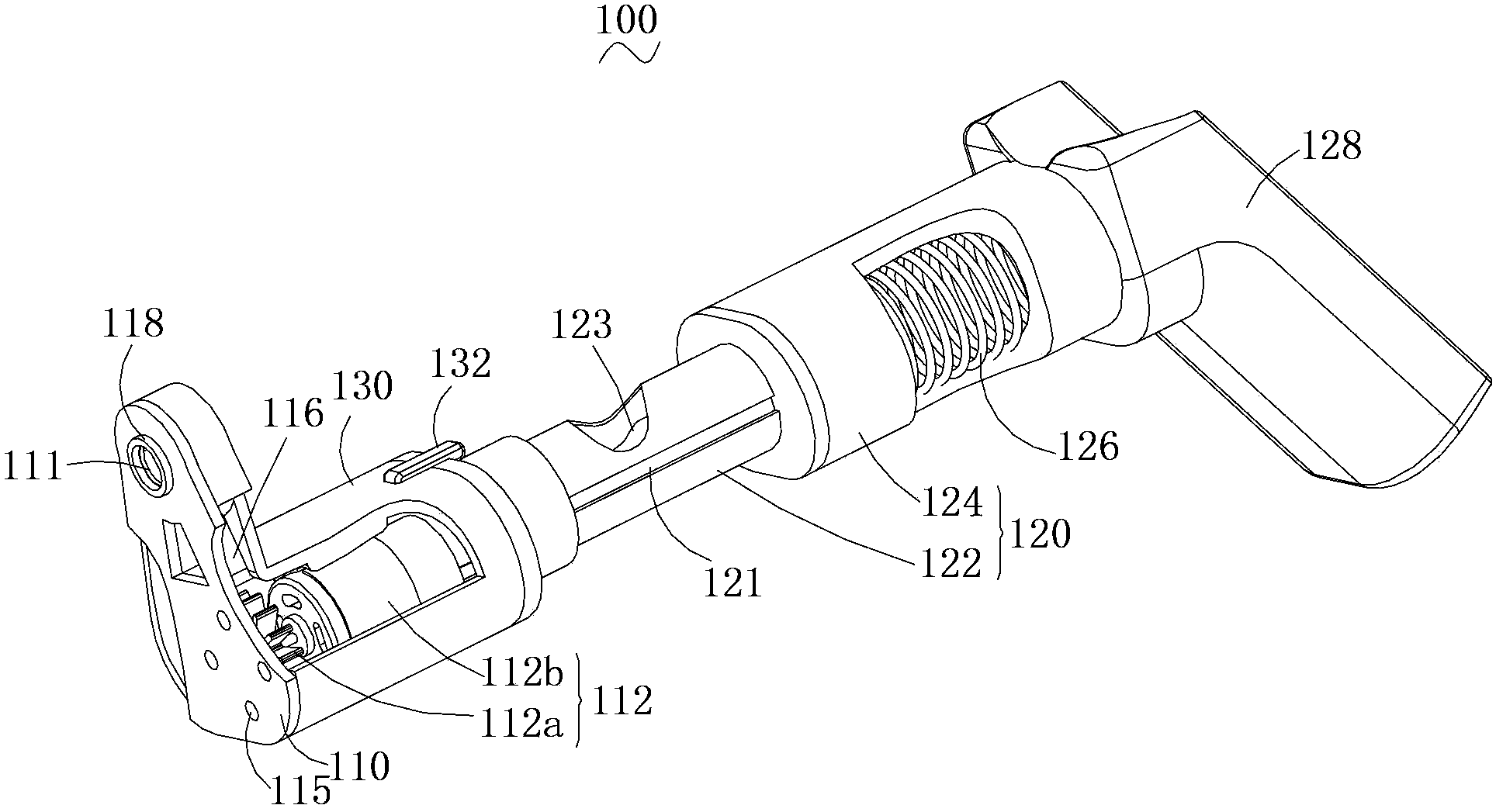

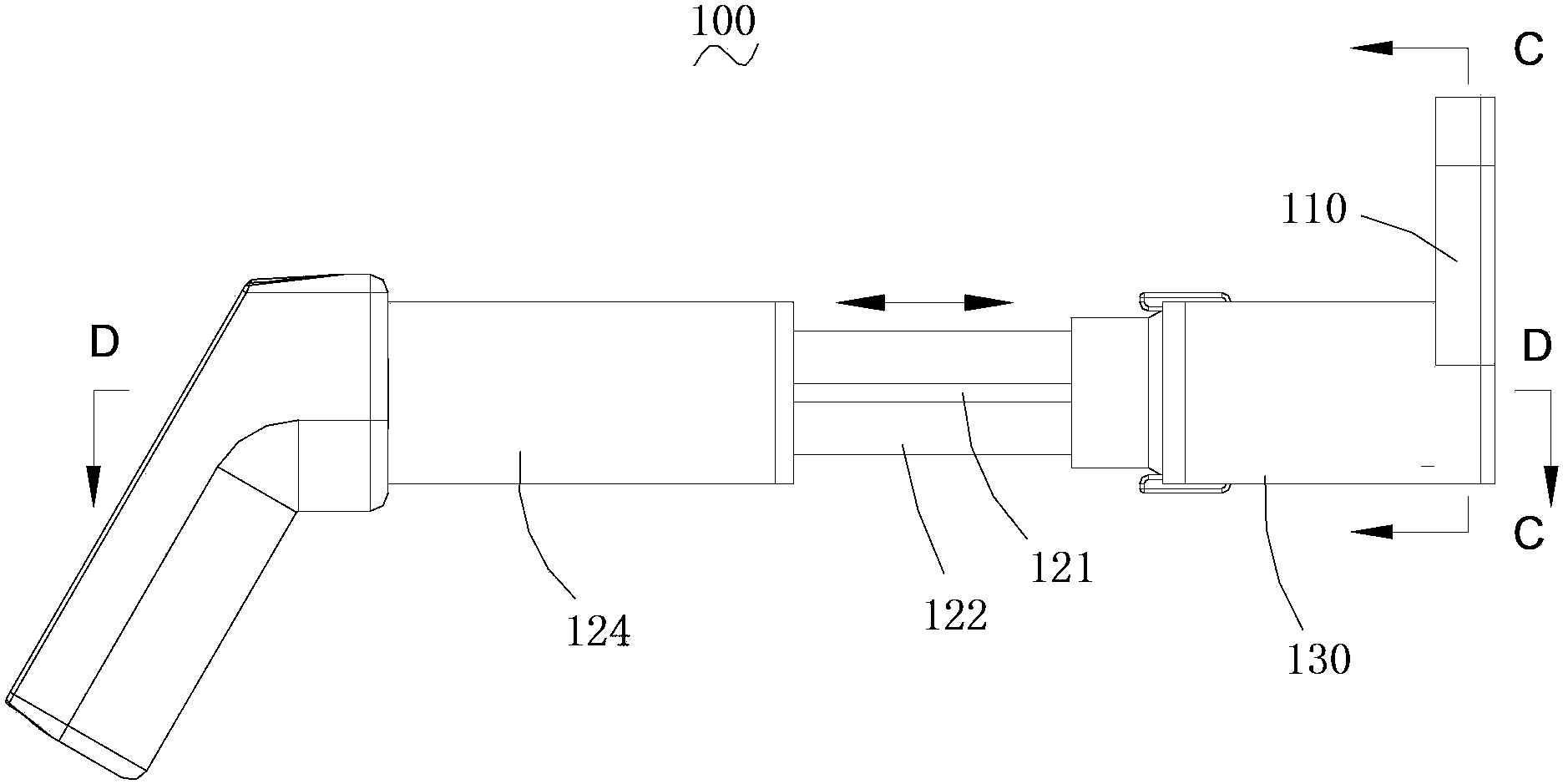

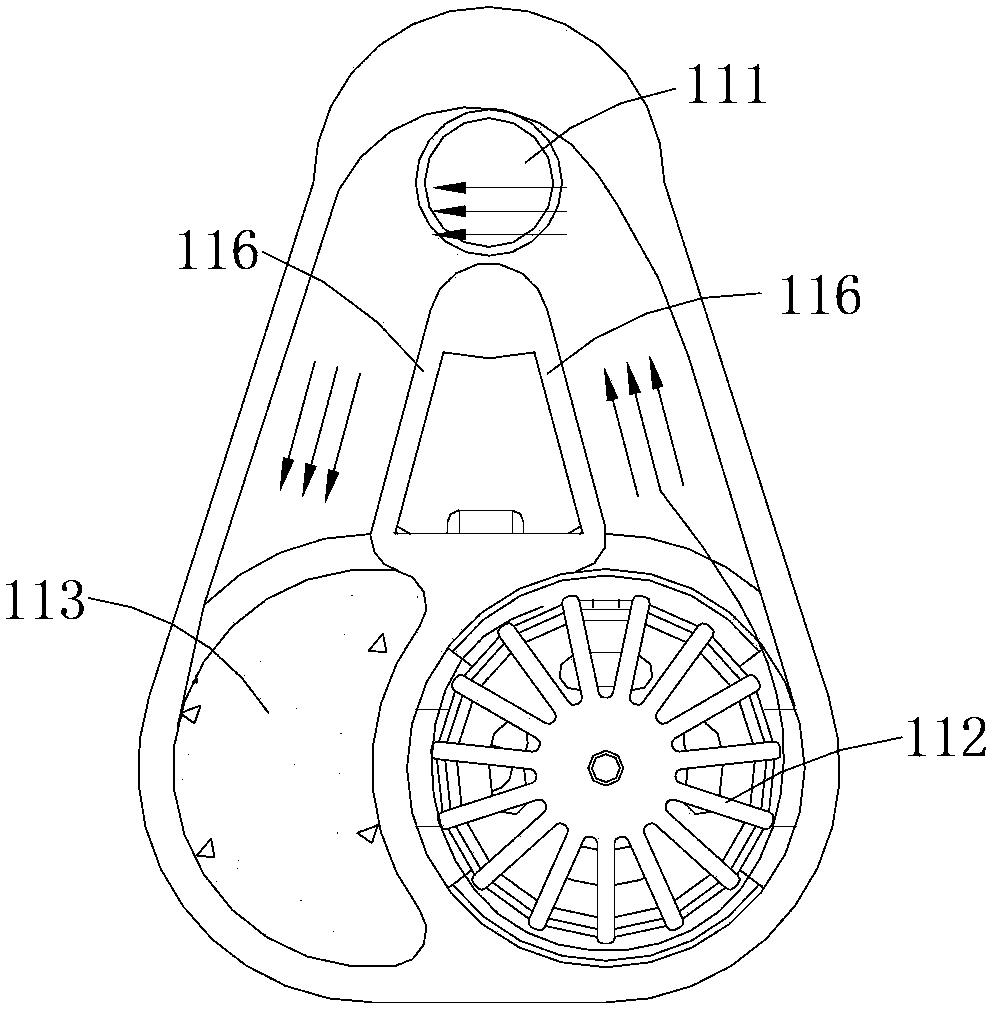

[0022] Please refer to figure 1 and image 3 , an embodiment provides an electric hammer blower 100 . The electric hammer dust blower 100 includes a dust blowing device and a telescopic rod 120 . The dust blowing device of the electric hammer dust blower 100 includes a base 110 and a support base 130 connected with the base 110 . In order to facilitate the observation of the internal structure of the electric hammer dust blower 100, figure 1 The electric hammer dust blower 100 was processed, and part of the housing of the dust blowing device and the telescopic rod 120 was dug out. The base 110 is fixed on the telescopic rod 120, and the telescopic rod 120 is provided with a mount 128 for fixing the telescopic rod 120 to the electric hammer. The base 110 is provided with a drill hole 111 allowing the drill bit of the electric hammer to pass through. The inside of the base 110 is provided with a fan 112 for blowing out an airflow, a dust collection chamber 113 for collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com