Crop straw wood-based panel and production method thereof

A crop straw and production method technology, which is applied in the field of crop straw wood-based panels and its production, can solve the problems of not meeting the requirements of different fiber fineness of the surface and core layers, restricting the production capacity of straw wood-based panel production lines, and increasing the difficulty of crushing with screens, etc. To achieve the effect of ensuring apparent quality and physical and chemical properties, reasonable and guaranteed morphological distribution, streamlining production line layout and control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] As an embodiment of the present invention, the production method of the crop straw-based panel comprises the following steps:

[0040] (1) Using a grass cutter to cut the wheat straw into 30mm grass sections, and control the moisture content of the grass sections at about 18%.

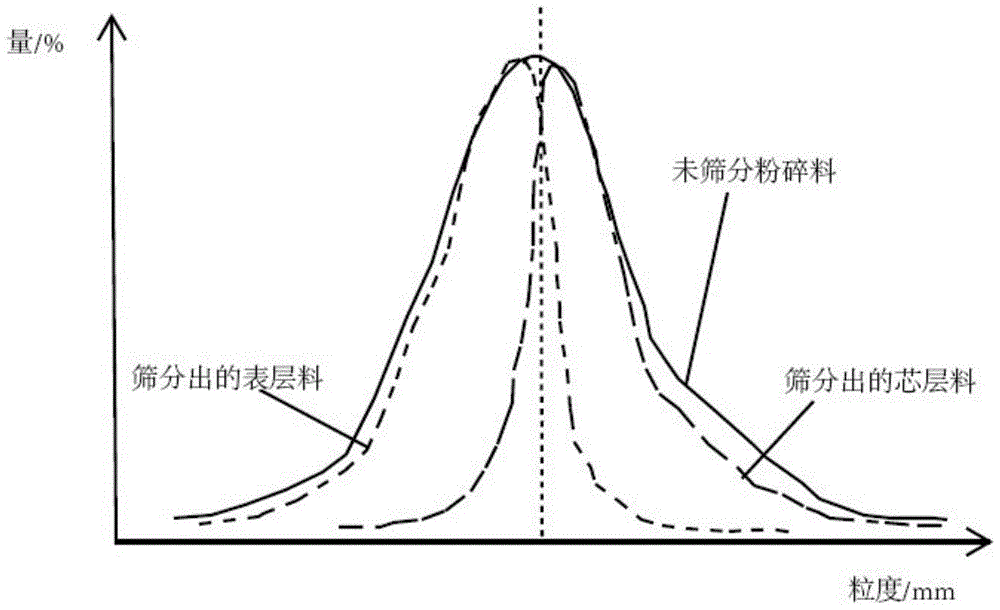

[0041] (2) adopt the pulverizer that the sieve mesh aperture of high power is about 8mm to pulverize described grass section, the fiber particle diameter size after pulverizing meets normal distribution, as figure 1 shown.

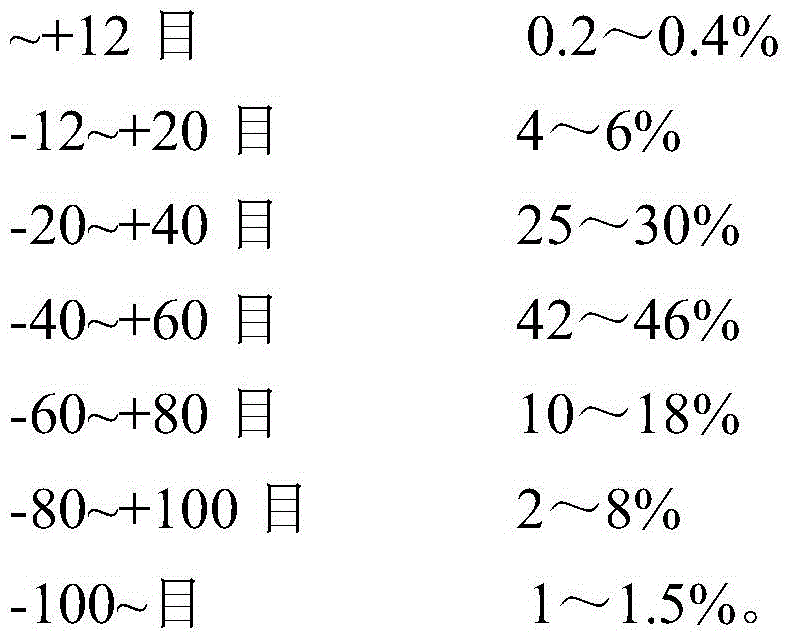

[0042] Specifically, the fineness of the pulverized fiber is represented by the mesh number of the vibrating standard sieve, and the sieving value of the pulverized fiber is shown in the following table:

[0043] Sieve type (mesh)

~+12

-12~+20

-20~+40

-40~+60

-60~+80

-80~+100

-100~

Mass ratio%

0.32

5.31

28.75

44.33

14.78

5.31

1.20

[0044] In this embodiment, three 2×132 double-shaft hammer mills are used, th...

Embodiment 2

[0054] As an embodiment of the present invention, the production method of the crop straw-based panel comprises the following steps:

[0055] (1) Using a grass cutter to cut the wheat straw into 33mm grass sections, and control the moisture content of the grass sections at about 17.5%.

[0056] (2) Adopt the pulverizer that high-power sieve mesh aperture is about 7mm to pulverize described grass section, the fiber particle size after pulverizing meets normal distribution, as figure 1 shown.

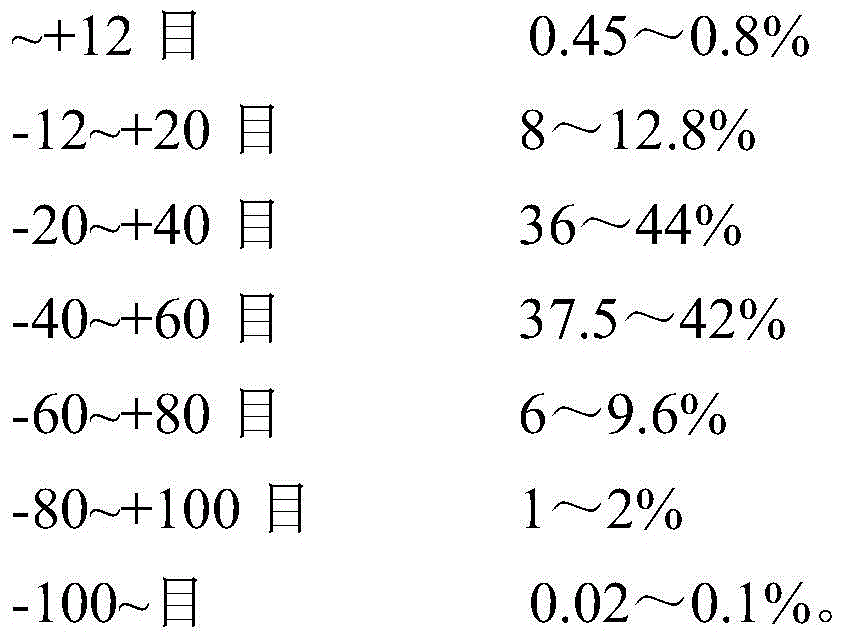

[0057] Specifically, the fineness of the pulverized fiber is represented by the mesh number of the vibrating standard sieve, and the sieving value of the pulverized fiber is shown in the following table:

[0058] Sieve type (mesh)

~+12

-12~+20

-20~+40

-40~+60

-60~+80

-80~+100

-100~

Mass ratio%

0.3

5.58

28.65

45.62

14.07

4.62

1.16

[0059] In this embodiment, three 2×136 double-shaft hammer mills are used, the production ca...

Embodiment 3

[0069] As an embodiment of the present invention, the production method of the crop straw-based panel comprises the following steps:

[0070] (1) Using a grass cutter to cut the wheat straw into 28mm grass sections, and control the moisture content of the grass sections at about 18.2%.

[0071] (2) adopt the pulverizer that the sieve mesh aperture of high power is about 8mm to pulverize described grass section, the fiber particle diameter size after pulverizing meets normal distribution, as figure 1 shown.

[0072] Specifically, the fineness of the pulverized fiber is represented by the mesh number of the vibrating standard sieve, and the sieving value of the pulverized fiber is shown in the following table:

[0073] Sieve type (mesh)

~+12

-12~+20

-20~+40

-40~+60

-60~+80

-80~+100

-100~

Mass ratio%

0.35

5.28

28.55

44.53

14.78

5.41

1.10

[0074] In this embodiment, three 2×132 double-shaft hammer mills are used, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com