Automotive Electric Power Steering System

A technology of electric power steering and automobiles, applied in the direction of electric steering mechanism, etc., can solve the problems of reduced service life of EPS assembly, low driver comfort performance, complex sensor structure, etc., achieve fast response speed, eliminate assembly hidden dangers, integrate The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] "Left", "right" and "inner" and "outer" orientation words involved in the present invention are all associated with the appended Figures 1 to 5 in the same direction.

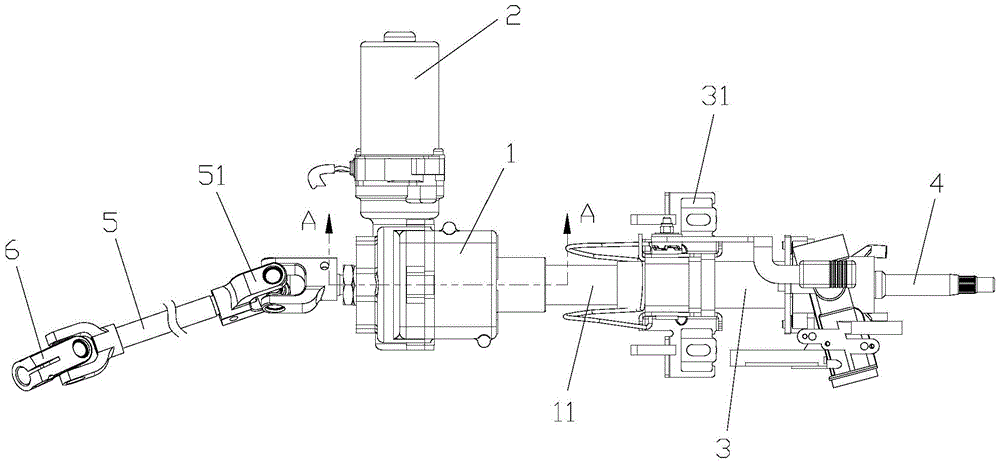

[0028] Such as Figures 1 to 6 As shown, the automobile electric power steering system of the present invention includes a worm gear box 1, a power assist motor 2, a steering column 3, a steering shaft 4, an intermediate shaft 5 and a nose yoke 6.

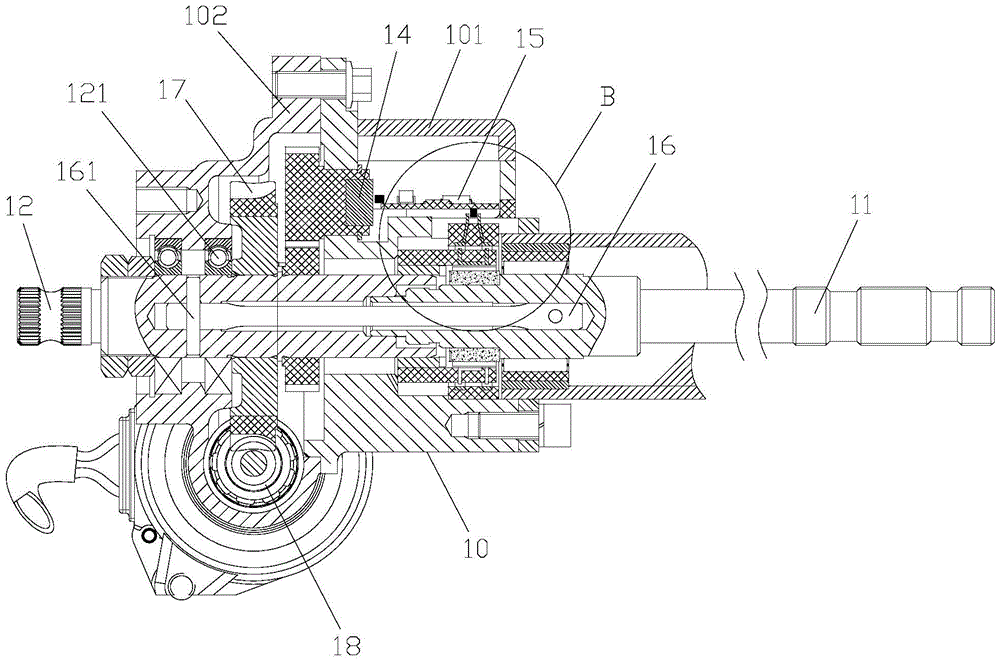

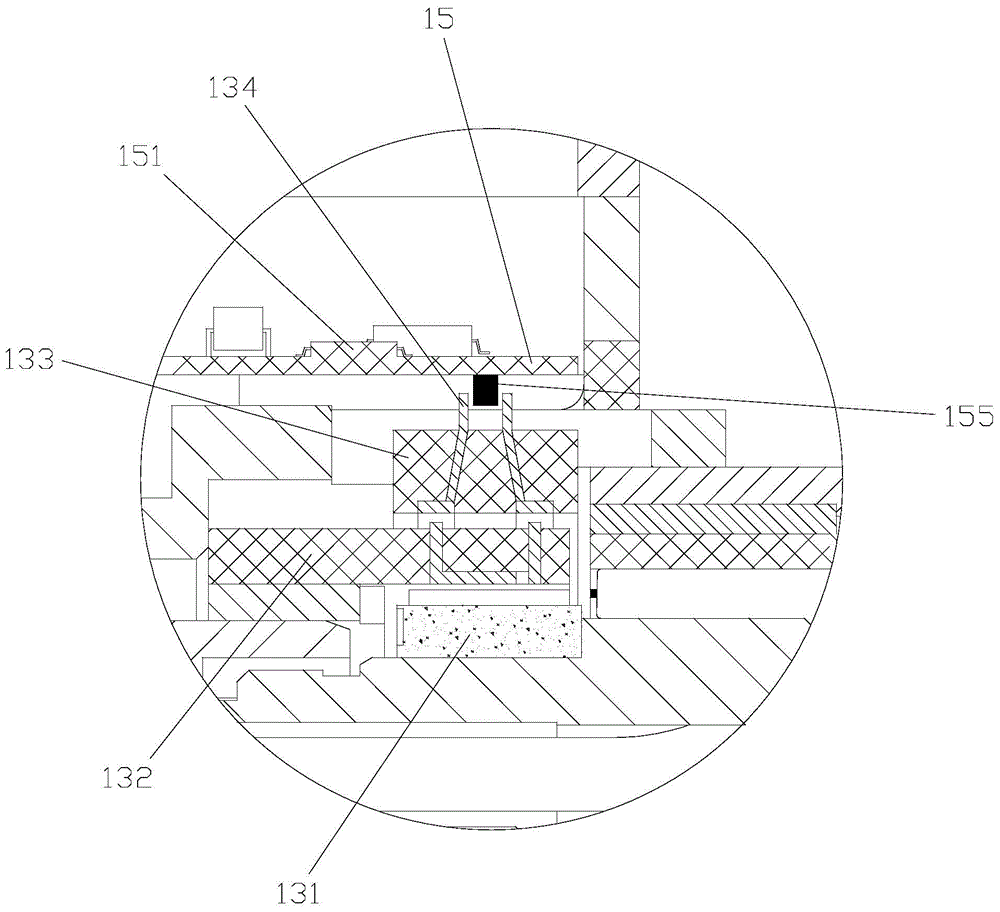

[0029] The worm gear box 1 includes a box shell 11 , an input shaft 11 , an output shaft 12 , a non-contact torque sensor 13 , a non-contact angle sensor 14 , a signal conditioning board 15 , a torsion bar 16 , a worm wheel 17 and a worm 18 .

[0030]Wherein, the casing 10 is composed of a left casing 101 and a right casing 102 assembled and connected; the input shaft 11 penetrates the casing 10 from the right casing 102 side; the output shaft 12 penetrates the casing 101 from the left casing 101 side. In the box shell 10, one end of the output shaft 12 pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com