Axial pay-off device capable of preventing shutdown wire accumulation

A pay-off device and axial technology, applied in the field of pay-off device and axial pay-off device, can solve the problems of loose wire rope and disordered wire, and achieve the effect of smooth process, convenient operation and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

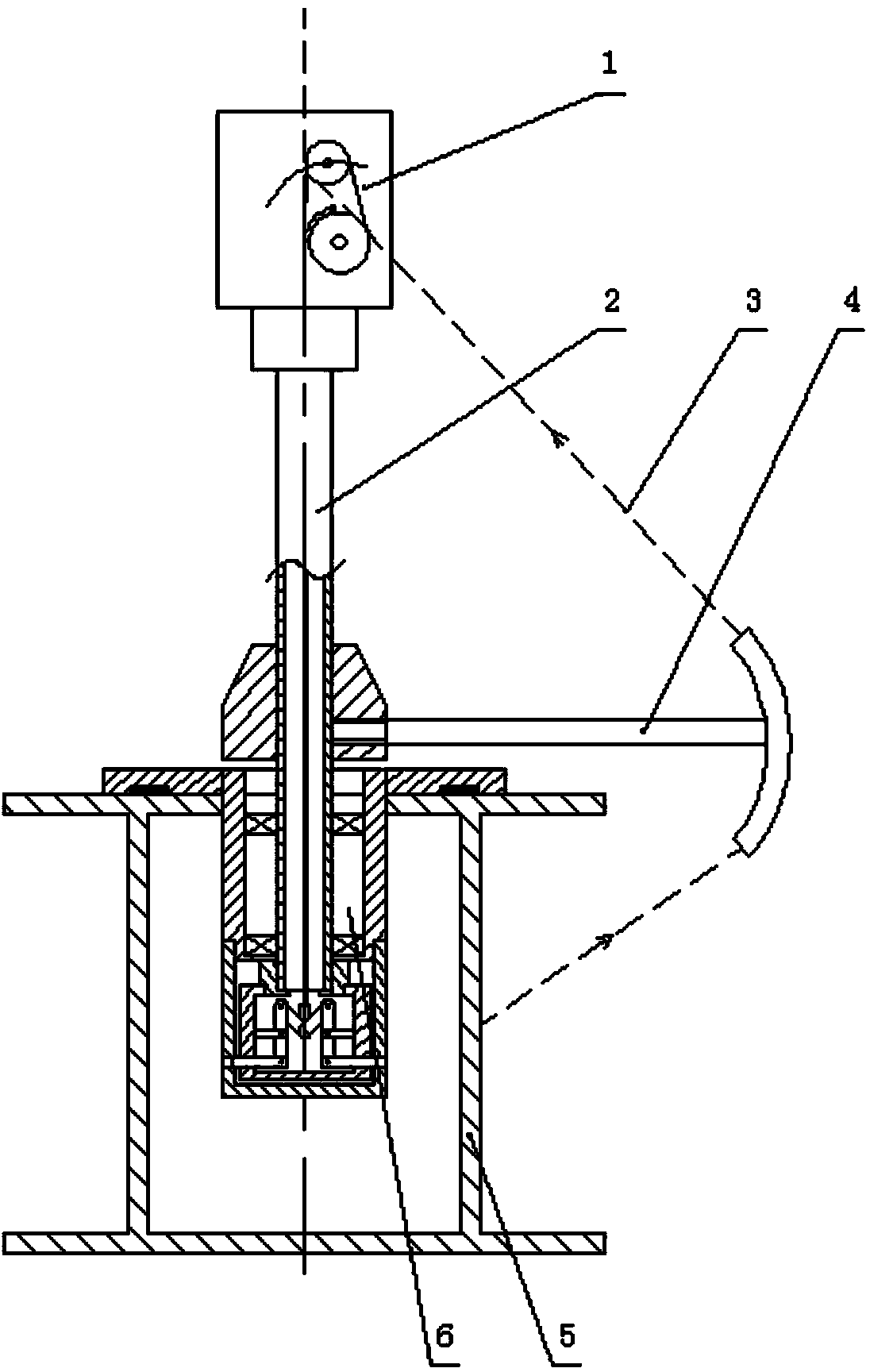

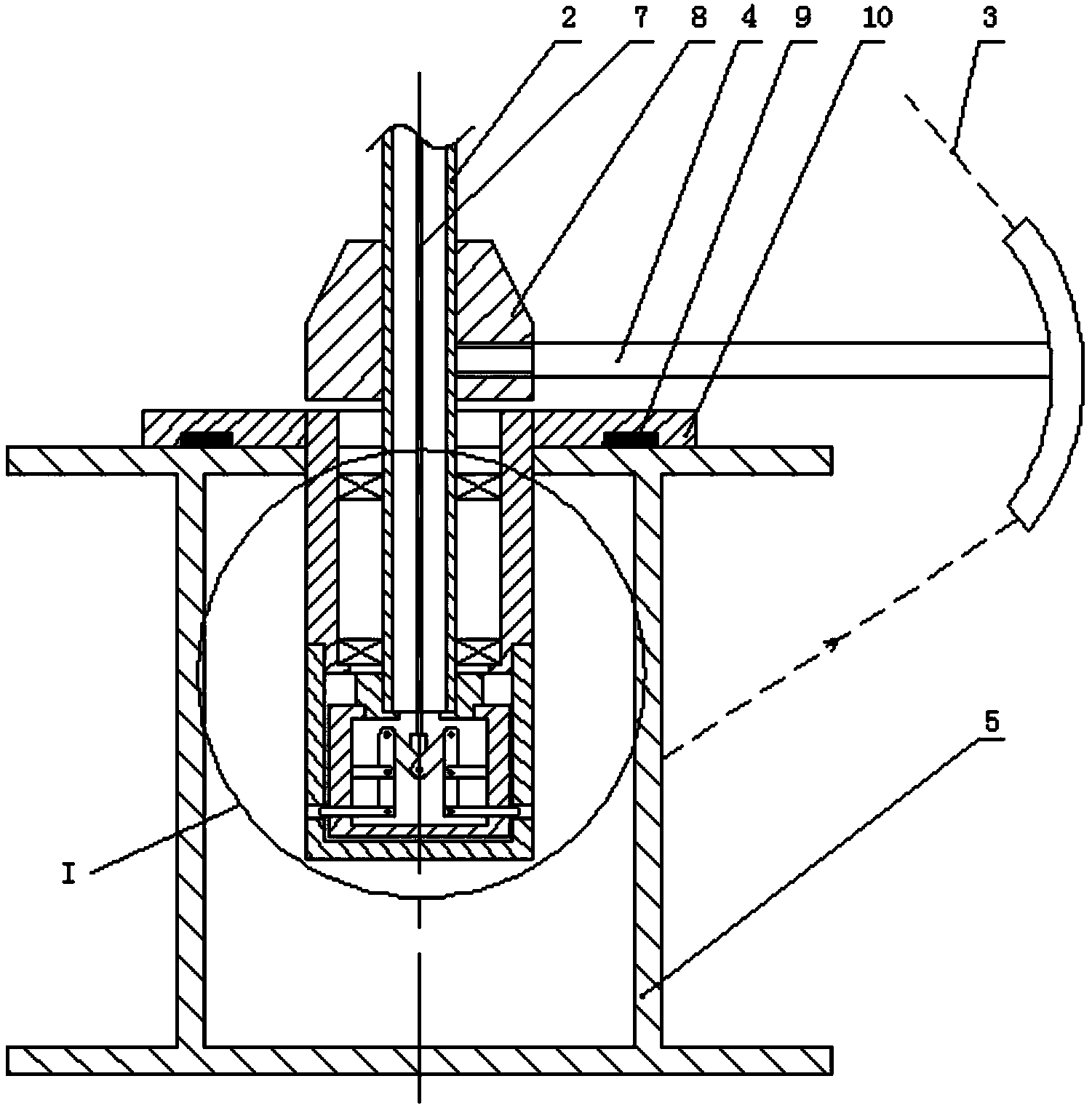

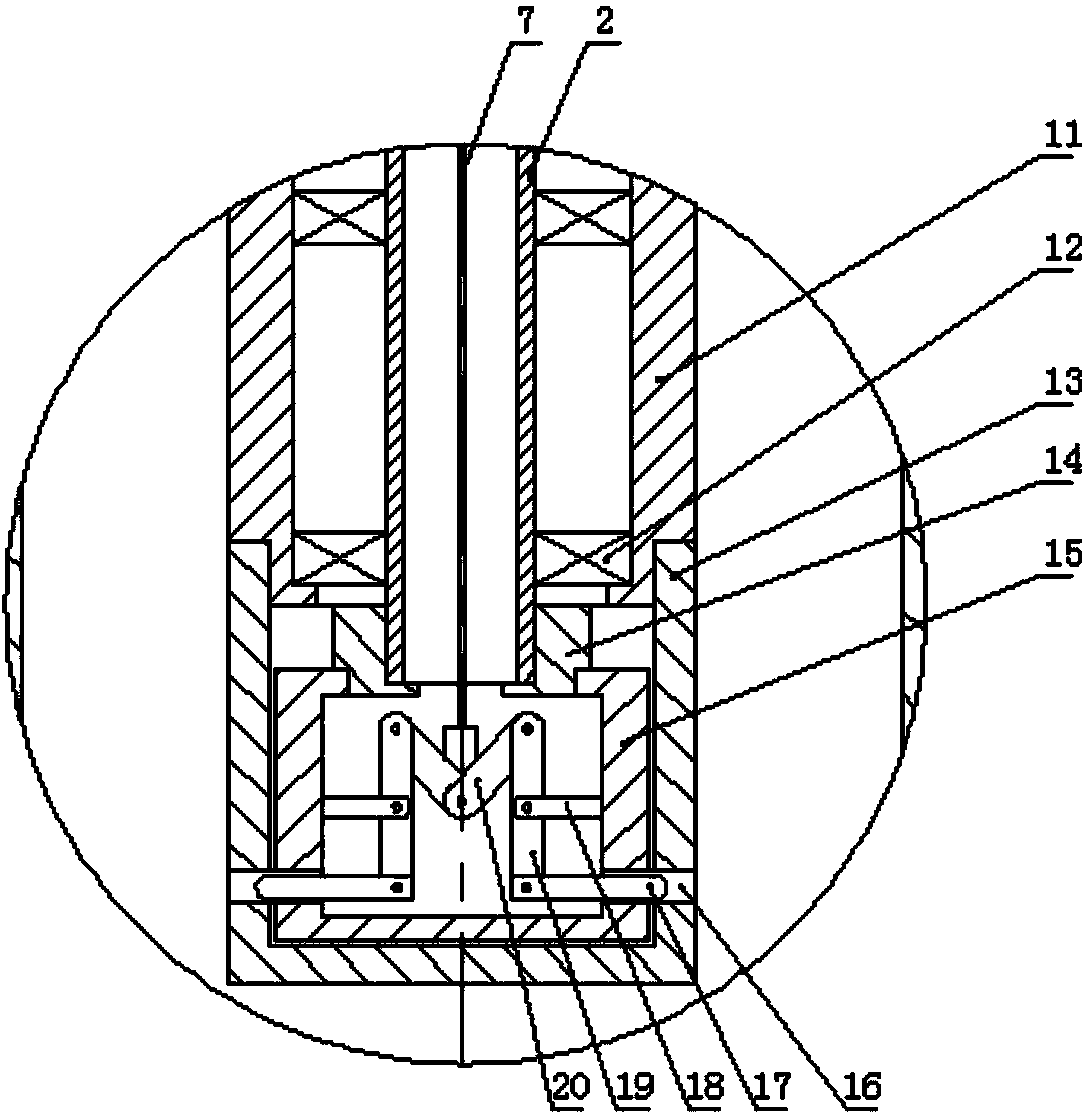

[0029] An axial pay-off device to prevent parking piles, such as figure 1 As shown, it includes a transmission line assembly 1, a brake assembly 6, a steel pipe 2, and a support cross bar 4. The brake assembly is coaxially embedded in the bobbin 5, and the outer casing of the brake assembly is fixed with the bobbin. The lower end of the steel pipe installed vertically is coaxially rotatable. The upper end of the steel pipe is fixed together with the transmission line assembly. The steel pipe above the bobbin is radially fixed to support the horizontal bar. The steel wire rope 3 wound around the bobbin passes through the supporting horizontal bar. The cantilever end of the rod and the transmission line assembly are straightened out, and the traction force generated by the straightening of the steel wire rope drives the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com