A strain of baker's yeast suitable for fermentation of dough without adding sugar and its breeding method

A baker's yeast and dough technology, which is applied in the field of bioengineering, achieves the effects of high dough rising ability, wide application prospects and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Construction of Baker's Yeast Suitable for Unsweetened Dough Fermentation

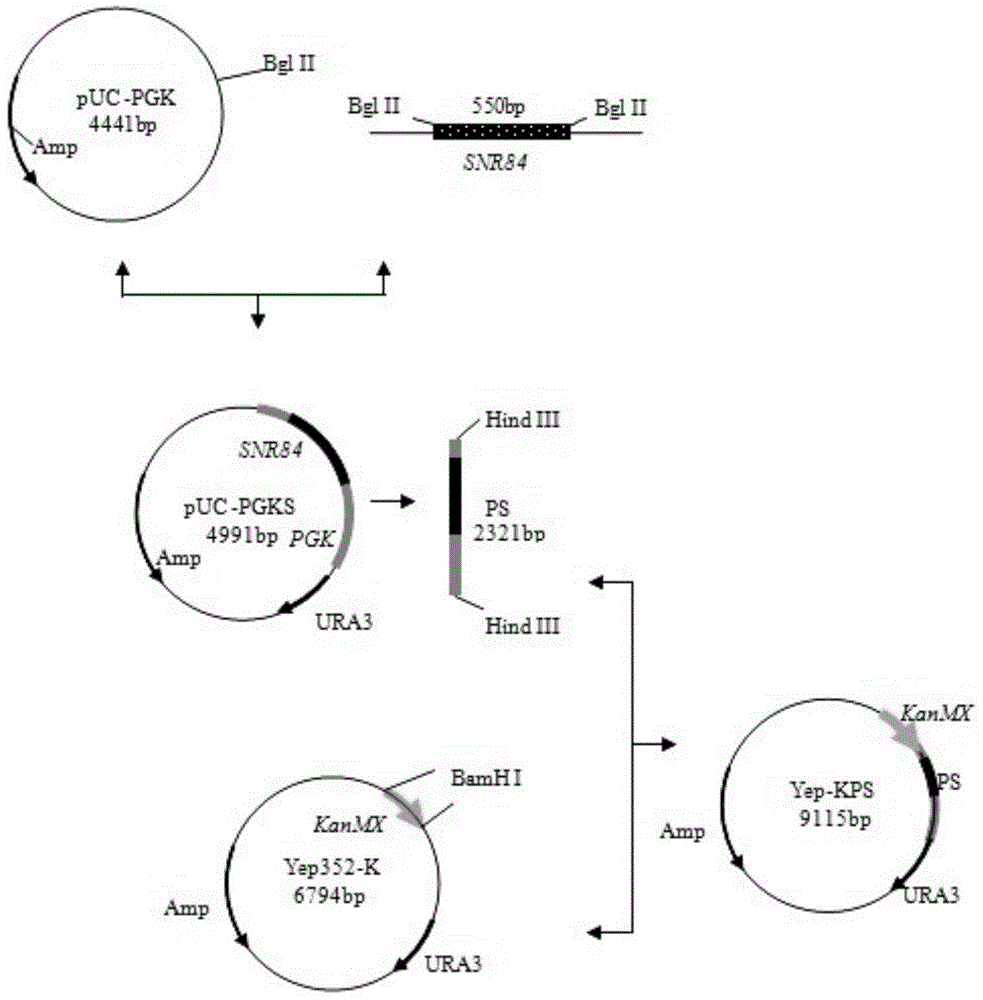

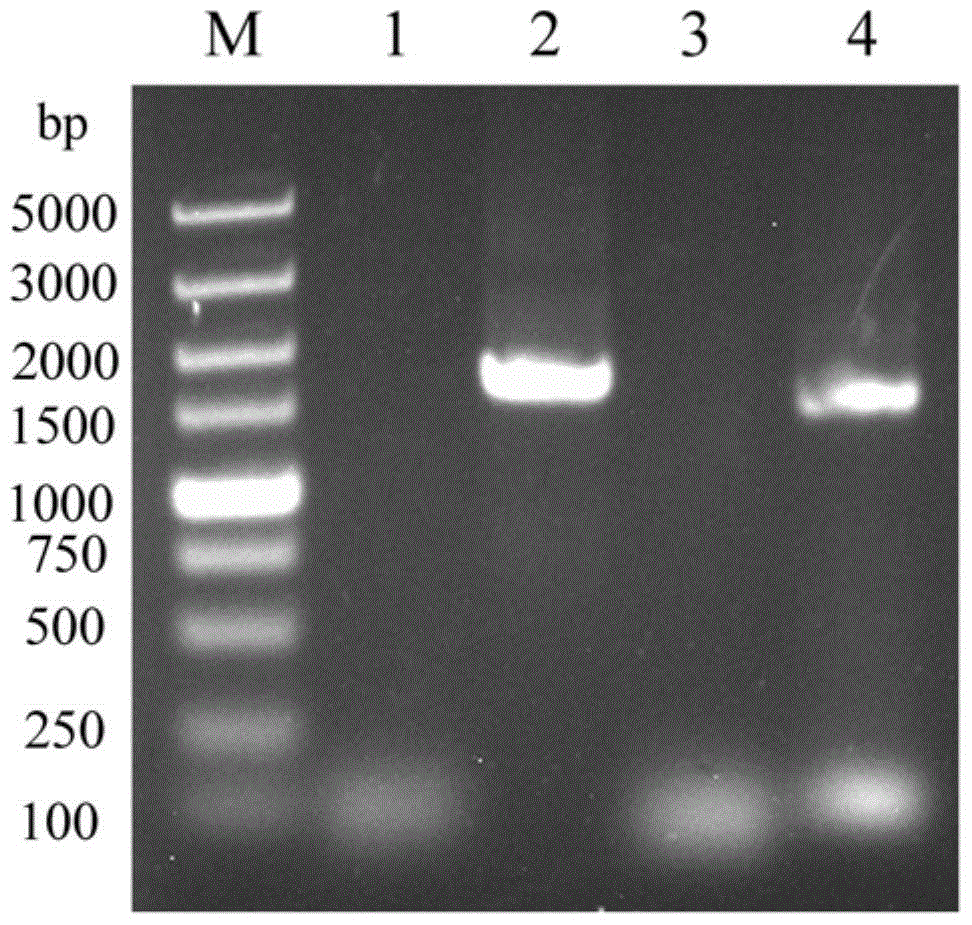

[0043] (1) Construction of expression plasmid Yep-KPS

[0044] The construction process of the expression plasmid Yep-KPS is as follows: figure 1 shown;

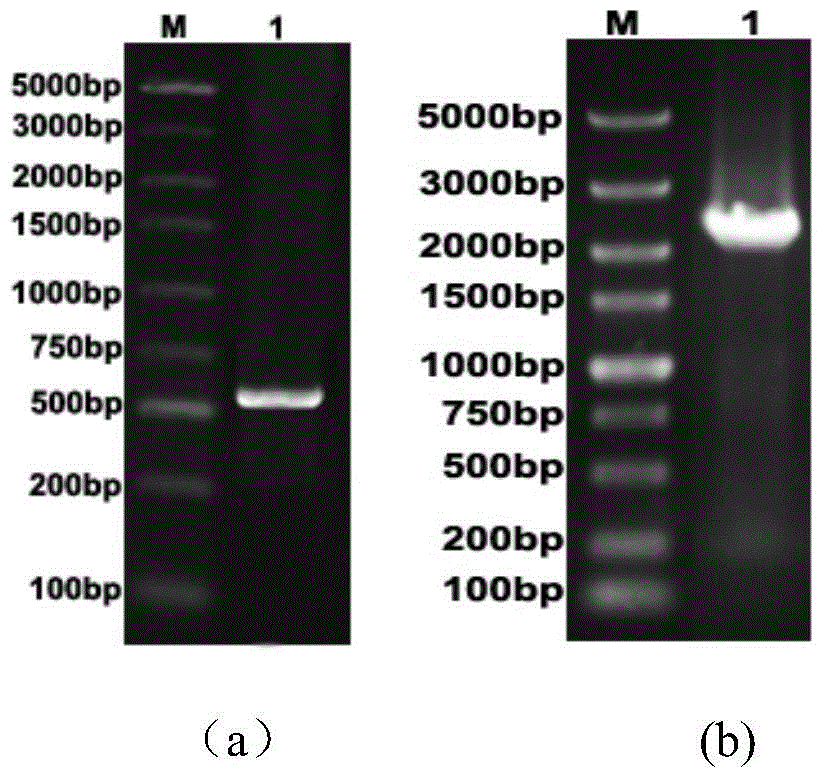

[0045] Using the total DNA of yeast strain CICC31616 as a template, the complete sequence of the SNR84 gene was amplified by PCR. The reaction system is shown in Table 1:

[0046] Upstream primer: 5'-GGA AGATCT ATTGCACAACTTAAGTTTGTCGAGG-3' (SEQ ID NO: 3);

[0047] Downstream primer: 5'-GGA AGATCT TAATGTGTCTCTTTGAGTCATGTTCCTT-3' (SEQ ID NO: 4); the underlined part is the enzyme cutting site;

[0048] The PCR amplification of table 1 SNR84 gene

[0049]

[0050] The PCR product was connected to the pUC-PGK1 vector containing a strong promoter to obtain pUC-PGKS; using pUC-PGKS as a template, PCR amplification obtained PGK inserted into the SNR84 gene P -SNR84-PGK T (PS) fragment, the reaction system is shown in Table 2;

...

Embodiment 2

[0071] Embodiment 2: The bread yeast fermentation experiment that is suitable for dough fermentation without adding sugar

[0072] (1) No-sugar-added dough fermentation experiments of recombinant strains and starting strains

[0073] Pick a ring of yeast cells in YEPD medium, 30 ℃, static culture for 24h; transfer to molasses medium with 10% (v / v) inoculation amount (add 0.5g / L Ammonium sulfate, 5g / L yeast powder), 30°C, 180r / min, cultivated for 24h to the stationary phase (OD 600 1.5 or so); statically cultivated for 2 hours, centrifuged at 4000r / min for 5 minutes, washed twice with sterile water, and collected the thalli for subsequent use.

[0074] Weigh 8.0 g of the above-mentioned yeast collected by centrifugation, mix it with 4.0 g of NaCl, 150 mL of water, and 280 g of standard flour, and put it into a preheated fermenter for fermentation. Record 1h CO 2 Gas production and the time to reach the maximum gas production.

[0075] (2) No-sugar-added dough fermentation e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com