Method for enhancing corrosion resistance and fatigue resistance of ocean structural steel

A fatigue performance, marine structure technology, applied in metal material coating process, fusion spraying, coating and other directions, can solve the problem of high maintenance cost, achieve the effect of strong corrosion resistance and fatigue resistance, and easy to be widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

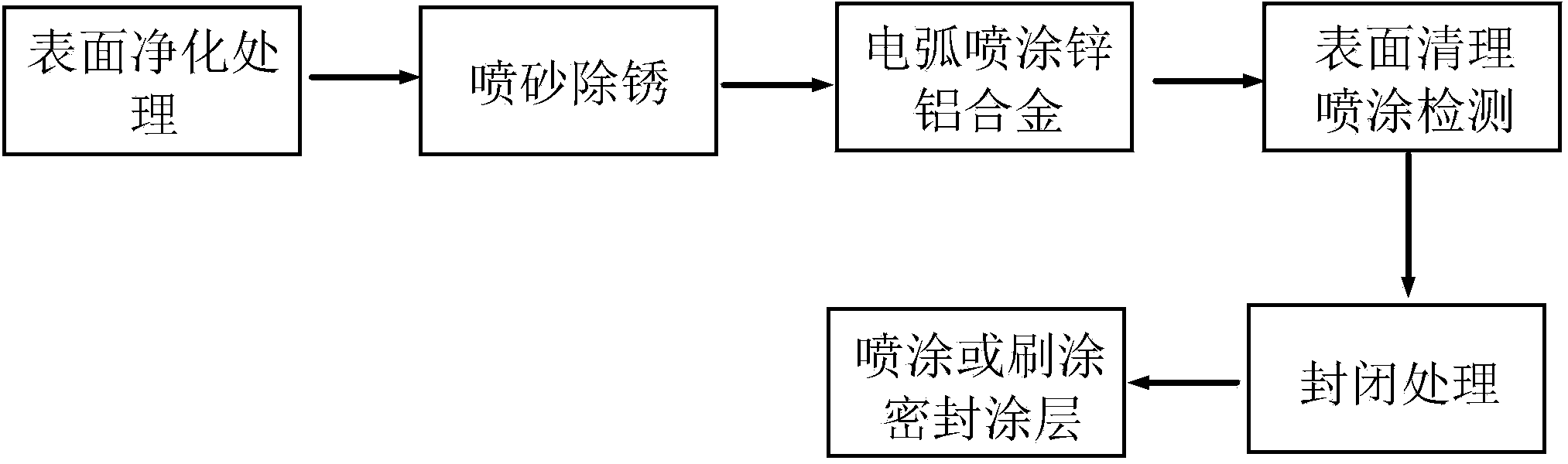

[0014] Such as figure 1 As shown, the method for enhancing the corrosion fatigue resistance of marine structural steel includes the following steps:

[0015] 1), surface purification treatment

[0016] Choose X80 structural steel, check the appearance of the structural steel workpiece, polish the surface burr and flash, and use manual or power tools to remove rust.

[0017] After treatment, there is no visible grease and dirt on the surface of the structural steel, no attached scale, rust and paint layer, the derusting result should meet the requirements of the national standard ISO8501-1Sa2.5, and the surface of the structural steel should show a uniform metallic luster. The surface roughness reaches 50-80μm.

[0018] 2), sandblasting and rust removal

[0019] In order to ensure the roughness and cleanliness of the metal surface, copper ore sand or corundum sand is used as the sandblasting abrasive, which has edges and corners. Keep it between 70 and 80 degrees.

[0020]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com