Aluminum oxide film forming method and sputtering device

A film forming method, aluminum oxide technology, applied in sputtering plating, ion implantation plating, coating, etc., can solve the problems of slow film forming speed, not suitable for mass production, poor production efficiency, etc., and achieve film forming speed high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be described below with reference to the drawings. In the drawings, the same reference numerals are attached to parts having the same structure and function, and repeated explanations will be omitted in the following description. In addition, each drawing is only a figure shown schematically, For example, the dimension, positional relationship, etc. of the thing shown in each drawing are not always shown accurately. In addition, in some of the drawings, XYZ orthogonal coordinate axes are added to illustrate directions. The direction of the Z axis among these coordinate axes indicates the direction of the vertical line, and the XY plane is the horizontal plane.

[0052]

[0053]

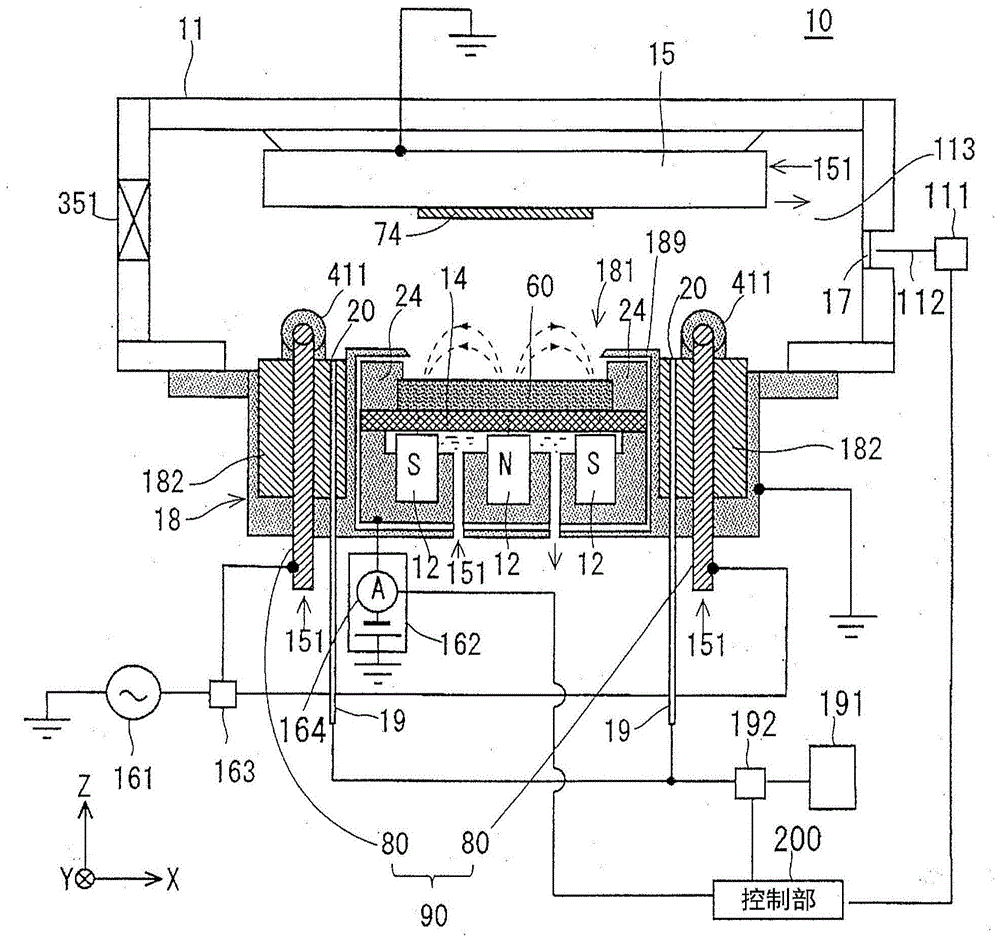

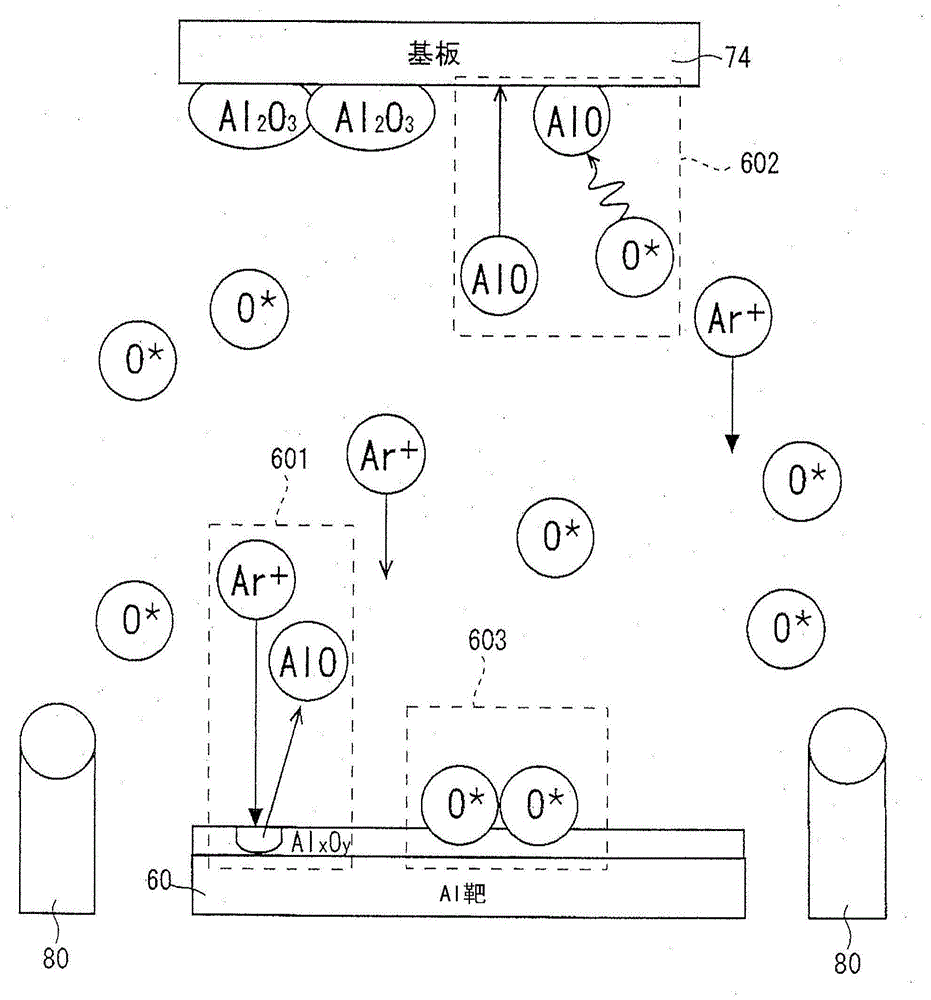

[0054] figure 1 It is a figure which exemplifies the schematic structure of the main part of the sputtering apparatus 10 for realizing the aluminum oxide film-forming method of embodiment. figure 2 It is a side view showing an example of the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com