A Pavement Structure for Heavy-duty Traffic Roads Based on High Stiffness Modulus Asphalt Mixture

An asphalt mixture and road pavement technology, which is applied in the direction of roads, roads, and on-site coagulation pavement, can solve the problem of not considering the gradation design and volume index of asphalt mixture, reducing the fatigue resistance of asphalt mixture, Considering the combination design of pavement structure and other issues, to achieve the effect of improving high temperature anti-rutting effect, low paving cost and good overall use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

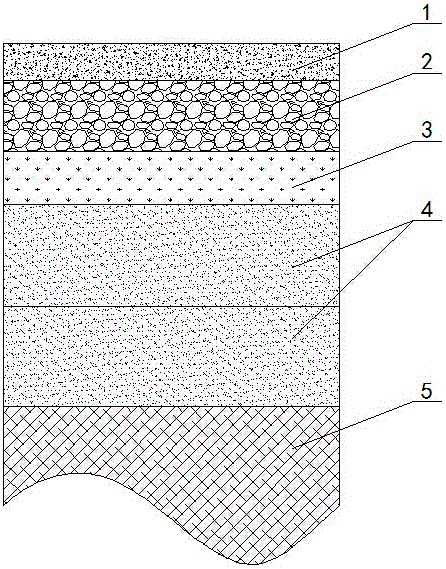

[0043] In the present invention, an anti-wear layer 1, an anti-rutting deformation layer 2, an anti-fatigue layer 3 and a semi-rigid base layer 4 constitute a complete heavy-duty traffic road pavement structure. The anti-wear layer 1, the anti-rutting deformation layer 2, the anti-fatigue layer 3, and the semi-rigid base layer 4 are laid on the subgrade 5 from top to bottom.

[0044] The anti-wear layer 1 adopts a broken gradation structure, the nominal particle size of the mixture is 9.5mm, the void ratio is 3.5%≤4%, and the thickness is 3-4cm. The gradation range of the asphalt mixture for the anti-skid wear layer is calculated based on the percentage of mineral materials of each particle size passing through the standard size sieve hole:

[0045]9.5mm, 90%~100%; 4.75mm, 28%~60%; 2.36mm, 20%~32%; 1.18mm, 14%~26%; 0.6mm, 12%~22%; 0.3mm, 10% -18%; 0.15mm, 9%-16%; 0.075mm, 8%~13%.

[0046]

[0047] The anti-rutting deformation layer 2 adopts a dense and graded skeleton str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com