Metering pump liquid release control device of post-processing system for internal combustion engine tail gas purification

A technology for exhaust gas purification and release control, which is applied in pump control, components of pumping devices for elastic fluids, liquid variable capacity machinery, etc., to maintain metering accuracy, reduce the influence of spray-assisted air pressure, and increase practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The words "upper", "lower", "left", "right" etc. used in the following to describe the orientation are based on the orientation shown in the drawings for the convenience of explanation. In the actual device, these Orientation may vary due to how the unit is positioned.

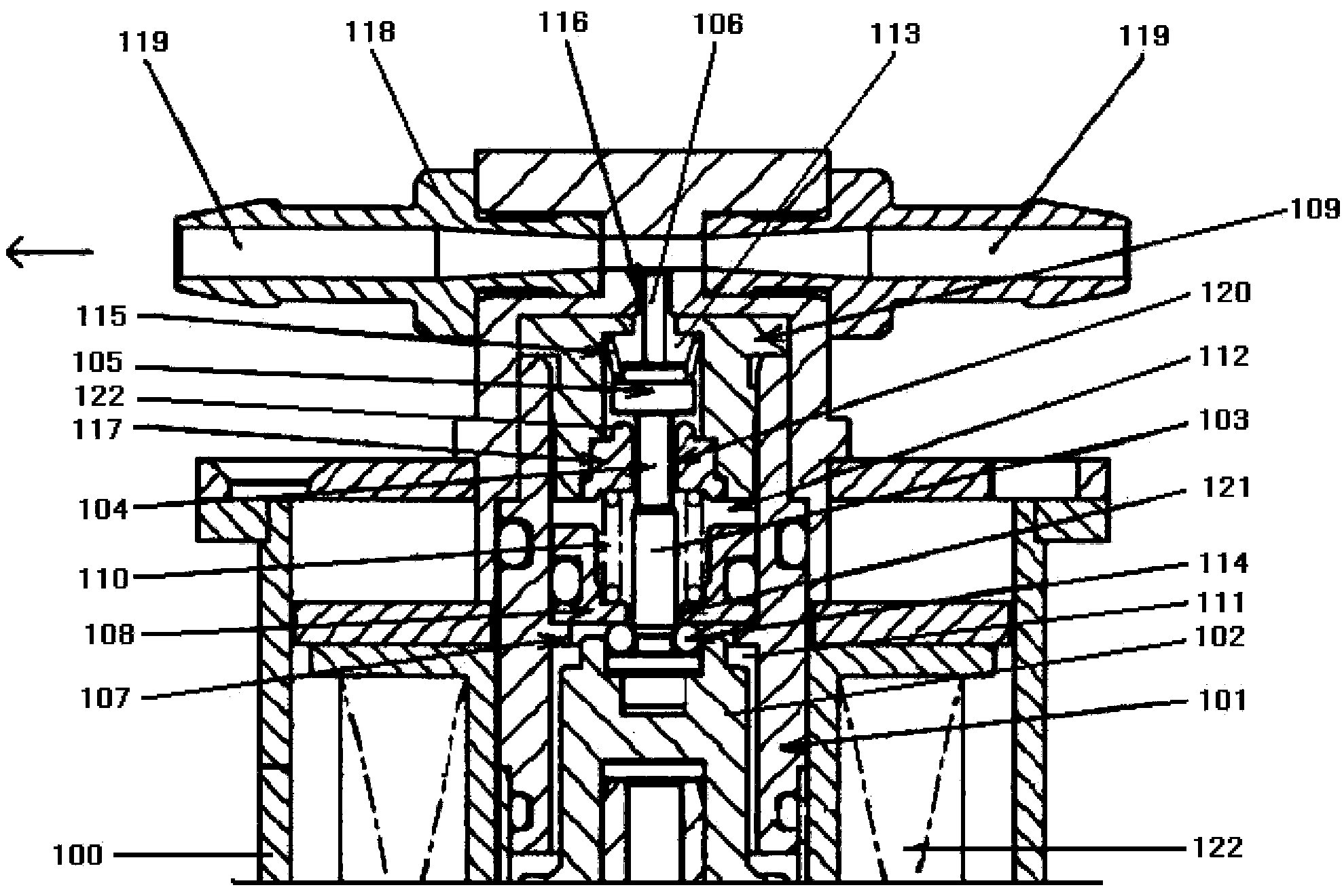

[0032] see image 3 As shown, a metering pump liquid release control device for a post-treatment system for exhaust gas purification of an internal combustion engine includes a metering pump housing 100, a metering pump cylinder 101 and a piston 102 disposed in the cylinder;

[0033] A push rod 103, a liquid release valve support rod 104, a liquid release valve 105, and a cleaning rod 106 are sequentially arranged above the piston 102; , that is, the central axes of the two coincide;

[0034] The metering pump cylinder 101 is provided with a piston running stop block 107, which is used to limit the stroke of the piston 102. When the piston 102 runs to the top, that is, it touches the piston running st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com