Exhaust device for elevator furnace system

A technology of exhaust device and bell jar furnace, applied in bell jar furnace, furnace control device, furnace and other directions, can solve the problems of blockage of safety pneumatic pressure reducing valve, high temperature, affecting the overall appearance of the workshop, etc. Diffusion, the effect of solving waterproof problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

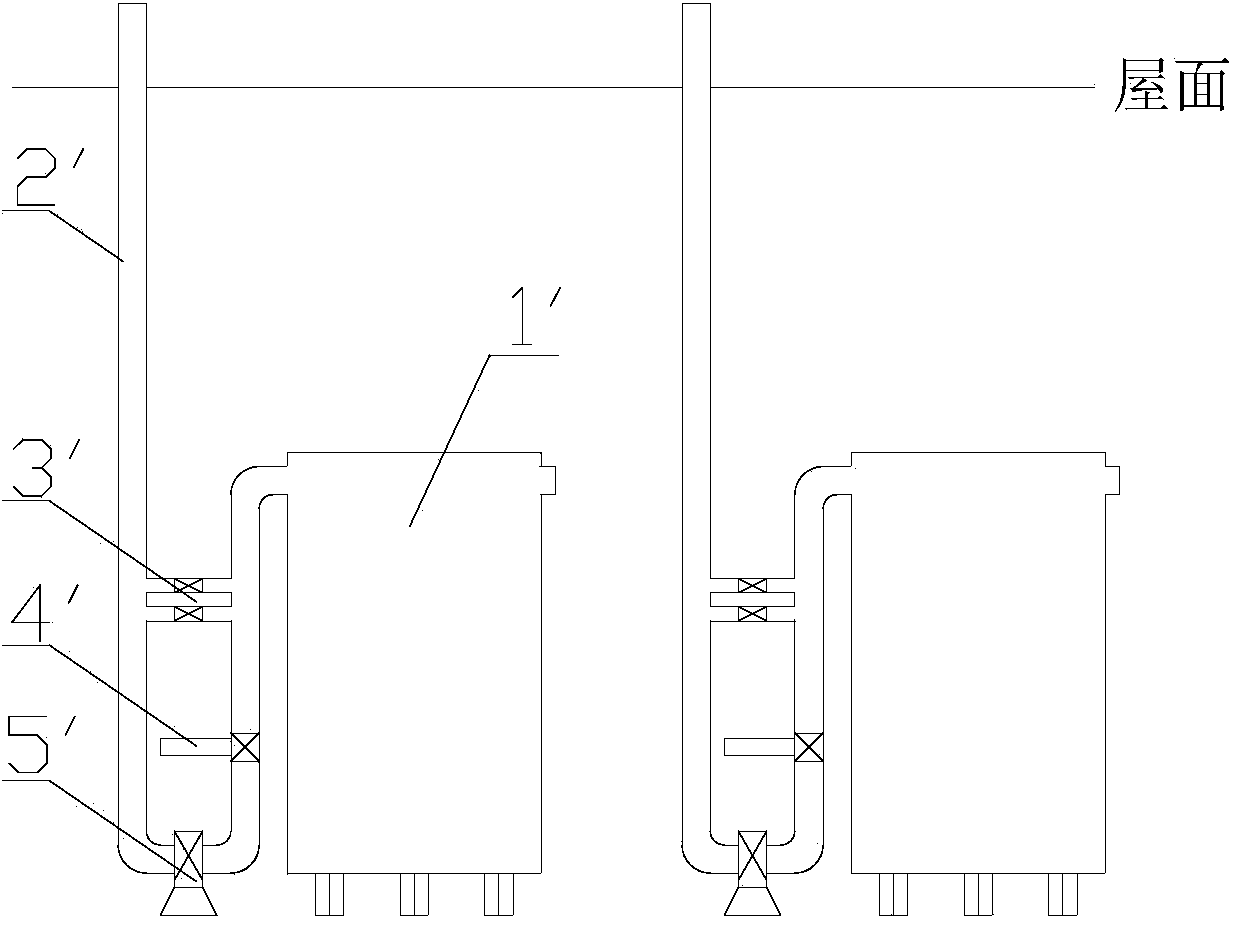

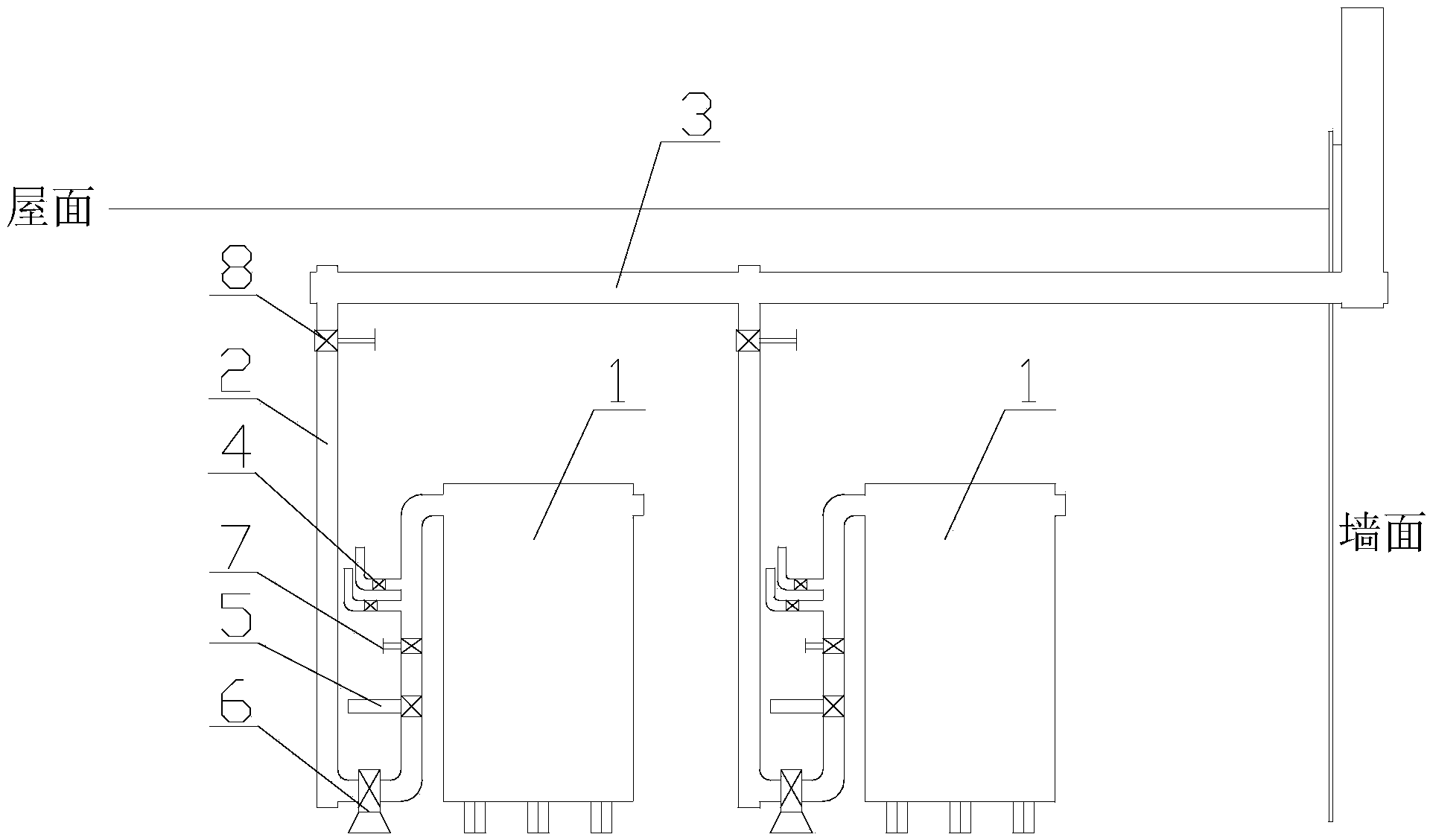

[0015] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an exhaust device of a bell furnace system proposed by the present invention.

[0016] refer to figure 1 , the exhaust device of a kind of bell jar furnace system that the present invention proposes, and described bell jar furnace system comprises M bell furnaces 1, and described exhaust device comprises M sub-row pipelines 2 and a total row pipeline 3, M The air inlets of the separate row pipes 2 are respectively connected to the gas outlets of the M bell furnaces 1, and the gas outlets of the M separate row pipes 2 are all connected to the main row pipe 3, and the general row pipe 3 passes through the wall and passes through the The fastening mechanism is fixed on the wall; along the exhaust direction from the air inlet end to the air outlet end of the distribution pipe 2, a safety pneumatic pressure reducing valve 4, an electromagnetic pneumatic valve 5 and an air exhaust valve are sequenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com