Dust detection and monitoring system for factory building

A monitoring system, dust technology, applied in the direction of measuring devices, suspension and porous material analysis, particle suspension analysis, etc., can solve the problems that the product cannot meet the requirements, there is no dust concentration monitoring in the factory building, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

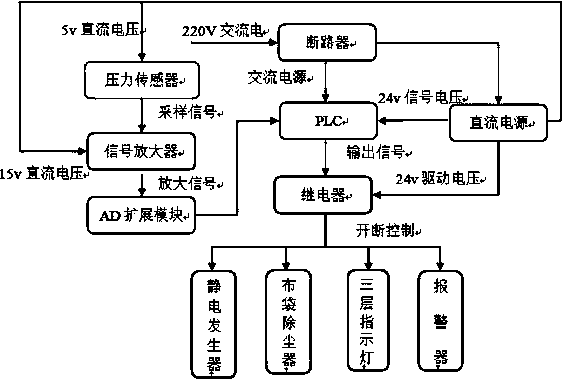

[0013] Such as figure 1 As shown, the plant dust detection and monitoring system of the present invention includes an electrostatic generator, which is arranged in the plant to be dust-removed; the electrostatic rod of the electrostatic generator is arranged in the HEPA filter paper cover, and the bottom of the HEPA filter paper cover is evenly distributed with multiple Pressure sensor; the pressure sensor collects the weight value of the filter paper cover and transmits the weight signal to the signal amplifier in the form of a voltage signal; the signal amplifier amplifies the weight signal and transmits it to the AD expansion module (digital-analog conversion module) in the form of analog quantity ; The AD expansion module converts the amplified analog signal into a digital signal and transmits it to the PLC (programmable logic controller);

[0014] PLC controls the on or off of electrostatic generator, bag filter, alarm and indicator light through relay;

[0015] The PLC avera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com