Temperature continuously-adjustable point-contact gas-sensitive humidity-sensitive test cavity

A gas-sensing, humidity-sensing, test chamber technology, applied in the field of gas-sensing and humidity-sensing sensor testing, can solve the problems of complex lead packaging, unable to provide a variety of temperature environments, and unable to test multiple sensitive components to be tested, etc., to achieve the internal volume Small, improve test accuracy, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

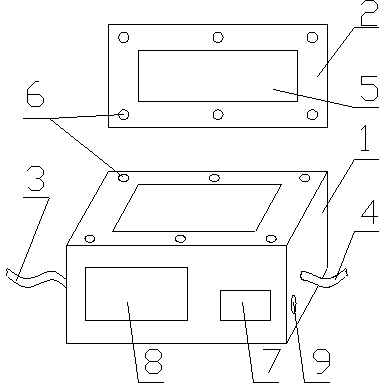

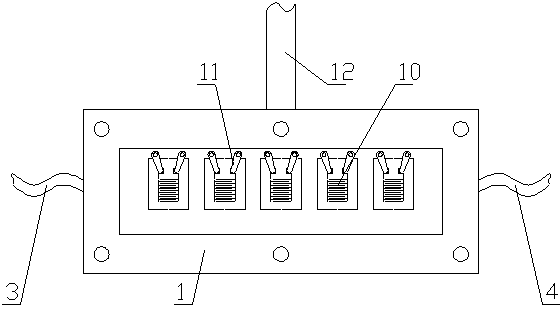

[0034] A temperature continuously adjustable point-contact gas-sensing and humidity-sensing test chamber is used for performance testing of gas-sensing elements or humidity-sensing elements.

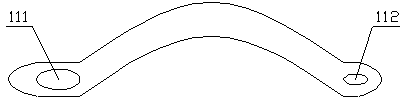

[0035]The test chamber includes a test chamber main body and a temperature control module. The main body of the test chamber includes a chamber body and a chamber cover. The chamber body and the chamber cover together form a sealed test chamber body. Both the chamber body and the chamber cover are made of polytetrafluoroethylene in the polymer material. The length of the cavity is 40mm-120mm, the width is 10mm-30mm, and the depth is 3mm-10mm. In this embodiment, the depth of the cavity inside the cavity is 3mm, the width is 10mm, and the length is 40mm. During the test, the cavity is along the length direction of the cavity. Set 4 to 6 gas sensors or humidity sensors. The cavity body and the cavity cover are correspondingly provided with threaded holes, and the cavity body and the cavit...

Embodiment 2

[0041] On the basis of Embodiment 1, the core control unit is made up of a single-chip microcomputer system, and its specific temperature control algorithm uses the existing Dahlin algorithm (the design of the entire controller of the Dahlin algorithm is based on a discrete method, and is designed in the Z domain. A suitable digital controller. The biggest feature of this algorithm is to design the expected closed-loop response of the system as an ideal first-order inertial link plus a pure lag link, and then use the expected closed-loop response transfer function and the mathematical model of the control system to find The regulator that gets the closed-loop response. The control system structure of the Dahlin algorithm is as follows: The controlled object is a first-order time-delay process: Where τ = NT, is the pure lag time. T is the sampling period, Tp is the time constant of the object, and Kp is the magnification factor. The desired closed-loop transfer function is:...

Embodiment 3

[0043] On the basis of Embodiment 1 or Embodiment 2, both the chamber body and the chamber cover are made of stainless steel among metal materials, the inner depth of the chamber body is 10 mm, the width is 30 mm, and the length is 120 mm. There are humidity sensitive elements in the cavity, and 6 humidity sensitive elements and 12 copper metal moving contacts are arranged in the cavity along the length direction of the cavity. When the material of the chamber body and the chamber cover is metal, the sealing gasket can be a corrosion-resistant flexible gasket or a rigid gasket. In this embodiment, the sealing gasket is a stainless steel gasket. The total length of the moving contact piece is 12mm, the length of the rotatable part of the moving contact piece is 10mm, and the diameter of the bump is 3mm; the distance between the moving contact piece is 15mm. The distance between the electrode connection points of the sensitive element to be tested is 10mm, and the width of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com