Long bar processing method and processing device

A processing method and a processing device technology, which are applied in the field of strip processing methods and processing devices, can solve the problems of reducing the adhesion strength of a dry film layer on the surface of a fixture, damaging the surface adhesion performance of the fixture, and reducing heat conduction efficiency, etc., to achieve improved Effects of heat transfer efficiency, improvement of heat transfer efficiency, and extension of etching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Several different preferred embodiments of the present invention will now be described with reference to the accompanying drawings, wherein like reference numerals in different drawings represent like parts. The invention provides a processing method and device for elongated strips. The processing method and device have high heat conduction efficiency and can prevent the elongated strips from being burned out during the etching process. The service life of the jig also makes the concave-convex shape formed on the ABS more precise, thereby improving the flying characteristics of the magnetic head, thereby improving the read and write performance.

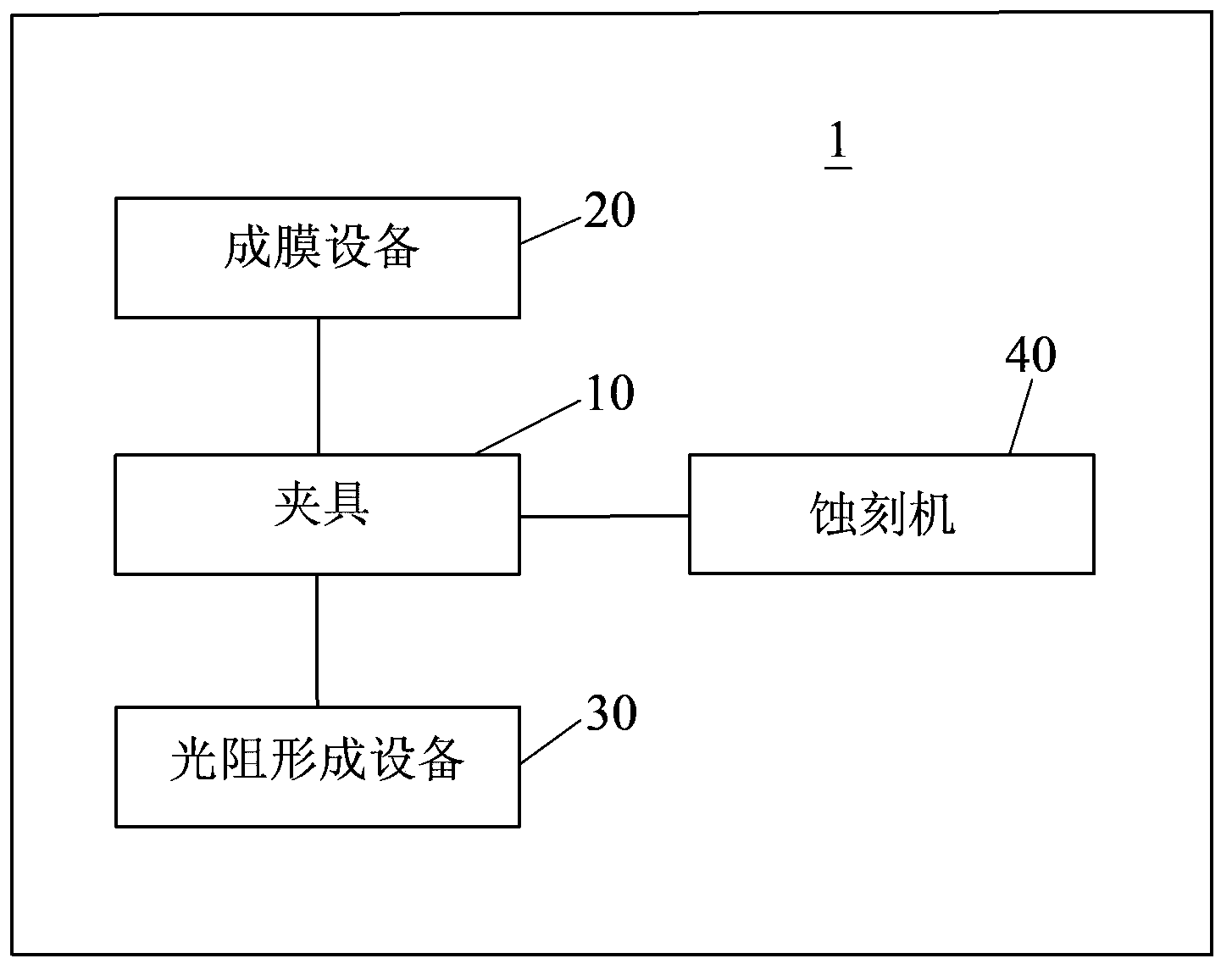

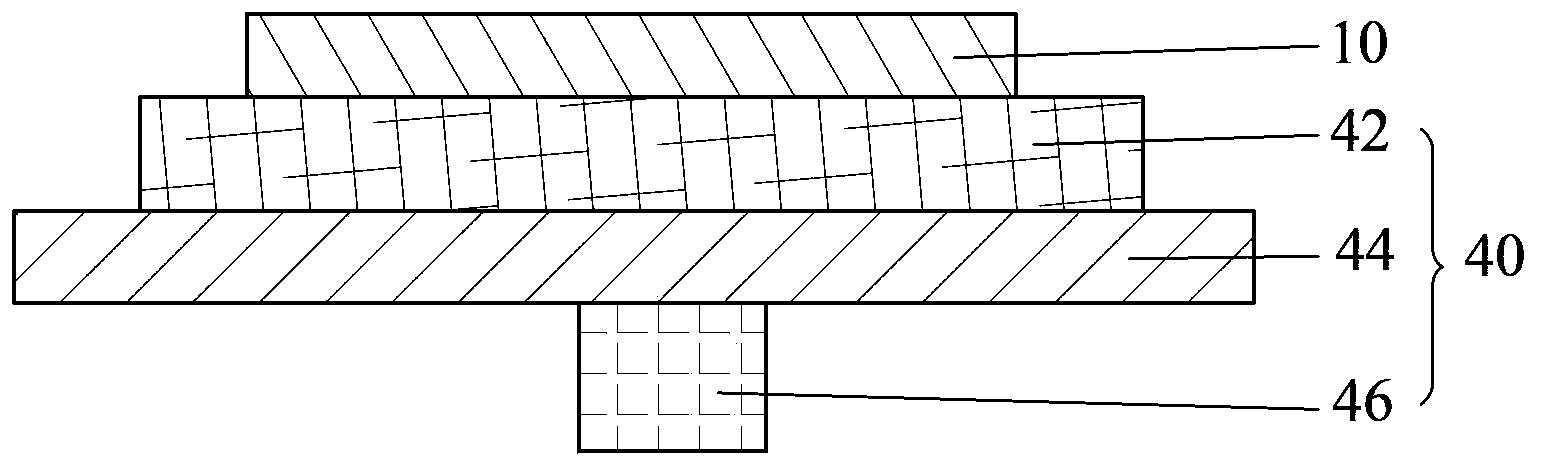

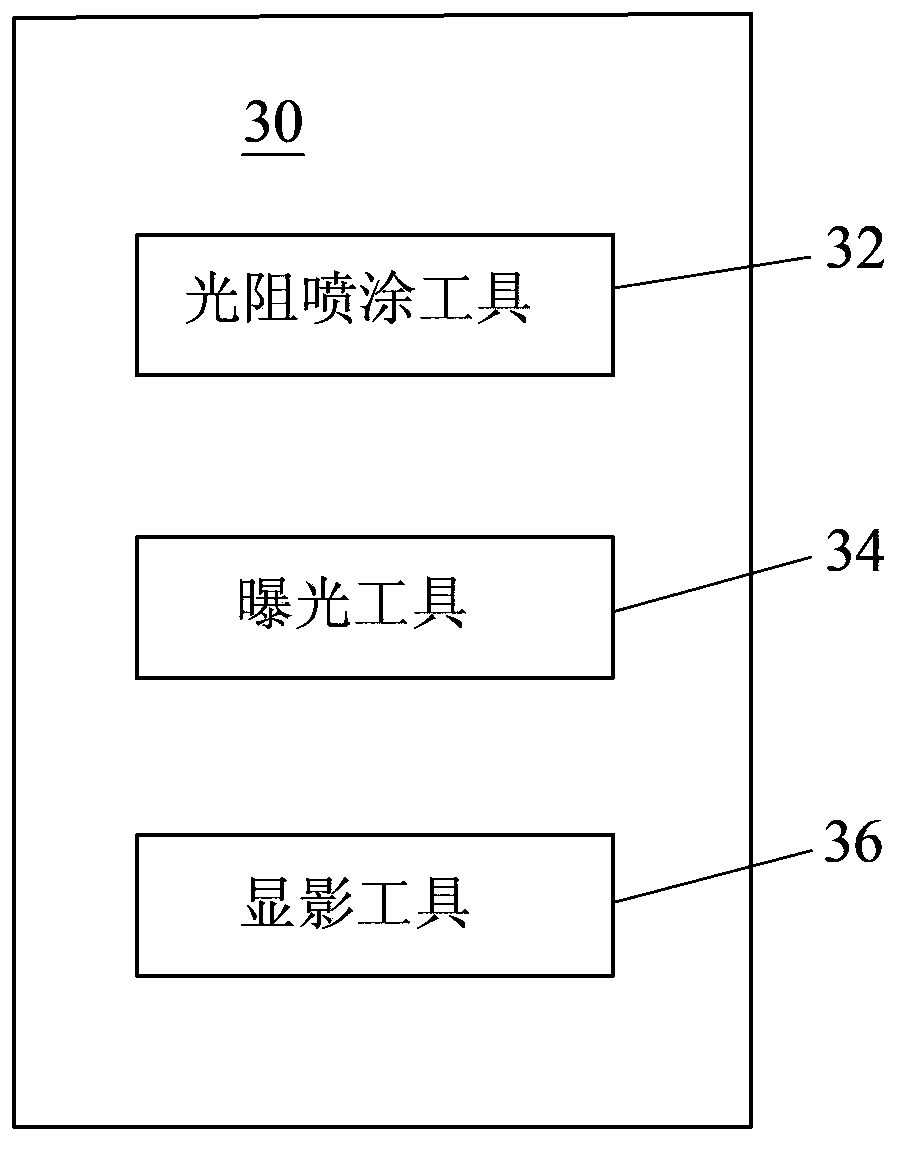

[0028] like figure 1 As shown, the processing device 1 of the present invention includes a clamp 10, film forming equipment 20, photoresist forming equipment 30 and etching machine 40, the clamp 10 is used to clamp the elongated strip and has an upper surface that matches the elongated strip, The film forming equipment 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com