Shimmy damping device for spaceflight imaging load shutter

A swing reducing device and load technology, which is applied in the direction of shutters, electromechanical devices, casings/covers/supports, etc., can solve problems such as spring damping fatigue and vibration excitation, achieve long working life, improve service life, and reduce invalid rotation The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

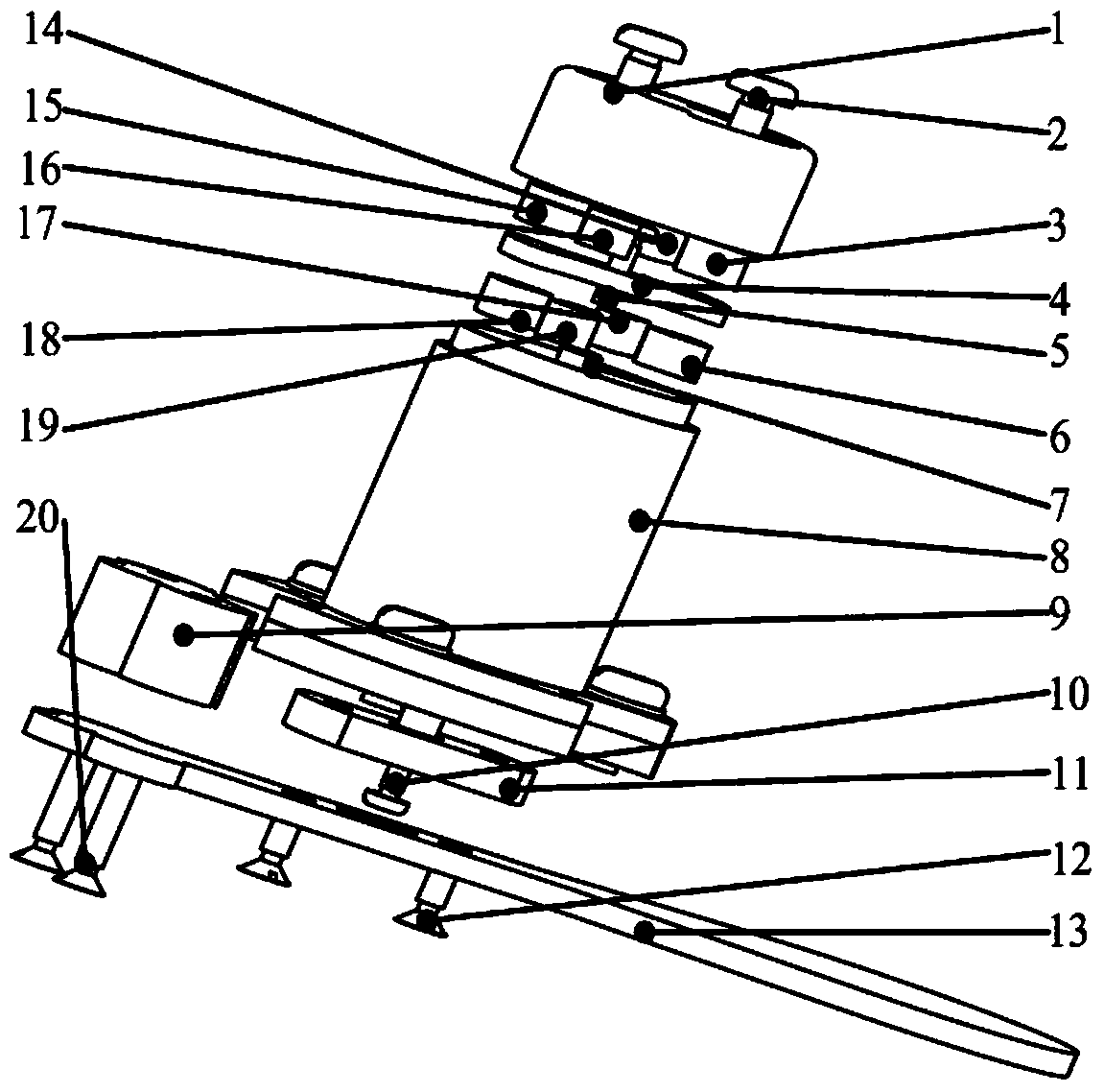

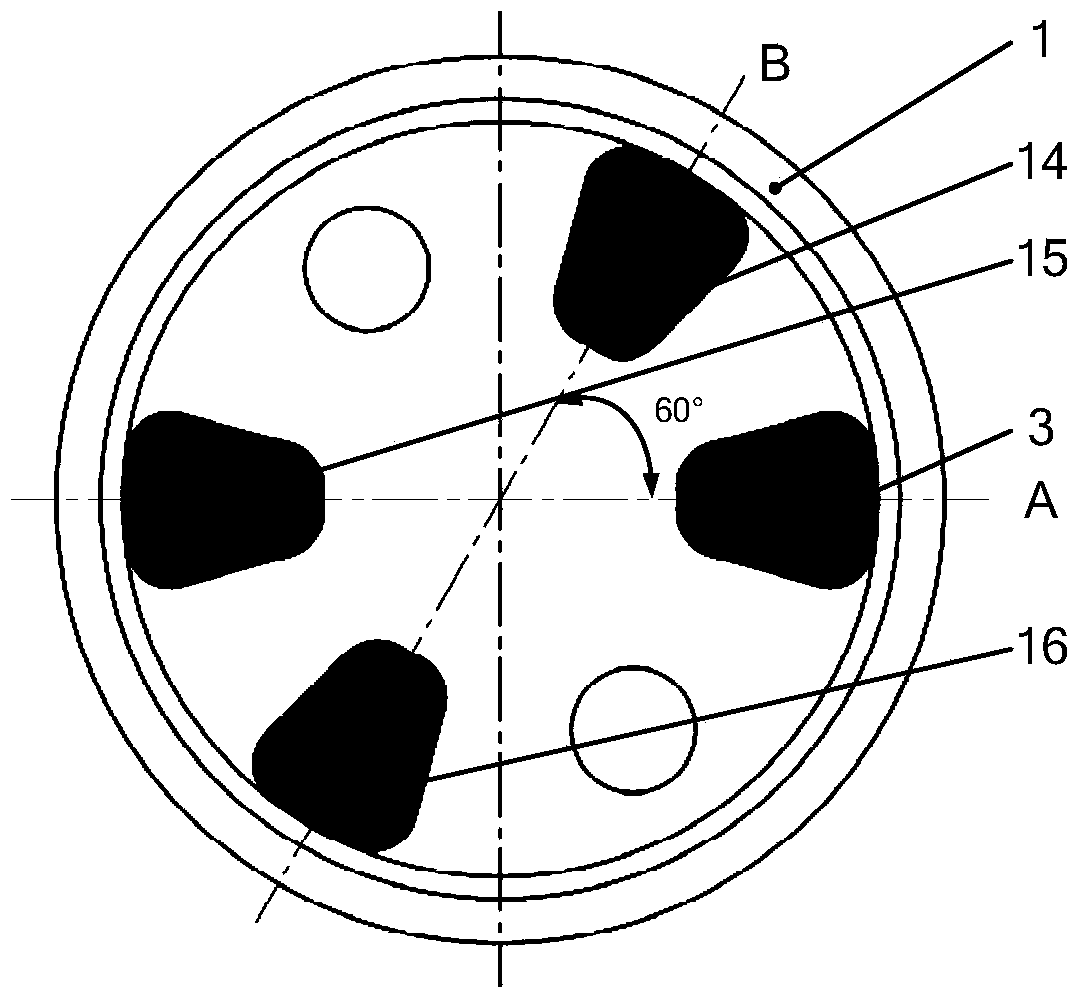

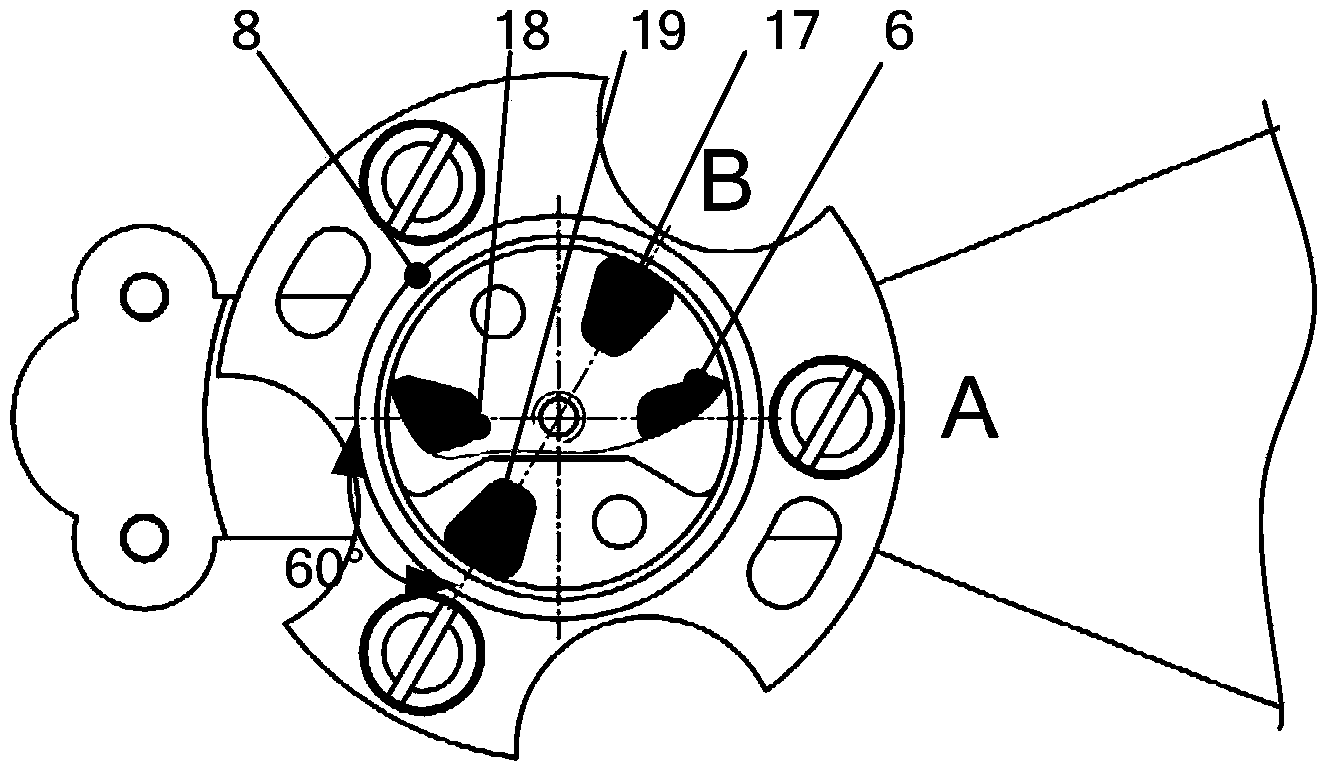

[0020] like figure 1 As shown, it can be seen from the three-dimensional exploded view of the shutter swing reduction device that the device mainly includes the rear end cover 1, the N pole samarium cobalt permanent magnets 3, 14, 15 and 16, the aluminum alloy swing reduction plate 4, and the S pole Samarium cobalt permanent magnets 6, 17, 18 and 19. Limited rotation angle torque motor 8 and shutter 13.

[0021] Combine below figure 1 , figure 2 and image 3 Further explaining the shutter sway reduction device of the present invention: the rear end cover 1 has an outer diameter of 40mm, a thickness of 10mm, and is made of TC4 titanium alloy. There are two Φ3.4 through holes on the edge for connecting with the motor 8 . There are 4 fan-shaped grooves in the rear end cover 1, the outer and inner diameters are 35m and 25mm respectively, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com