Reverse flexible corn stalk picking device

A corn stalk and flexible technology, applied in the field of agricultural machinery, can solve the problems of increasing the cost of corn stalk recycling products, restricting farmers' diversified product needs, lack of synchronous picking and cleaning devices, etc., to improve operation passability and improve obstacle crossing capacity, reducing the effect of straw splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

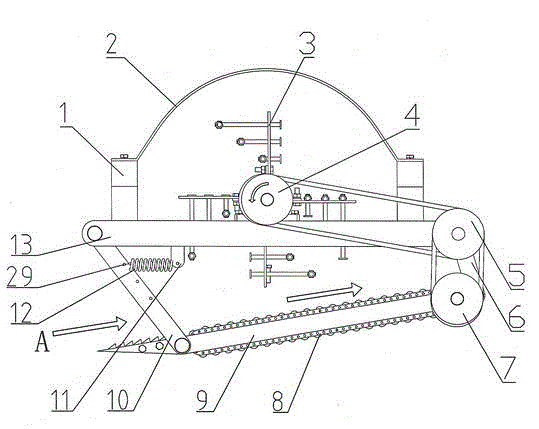

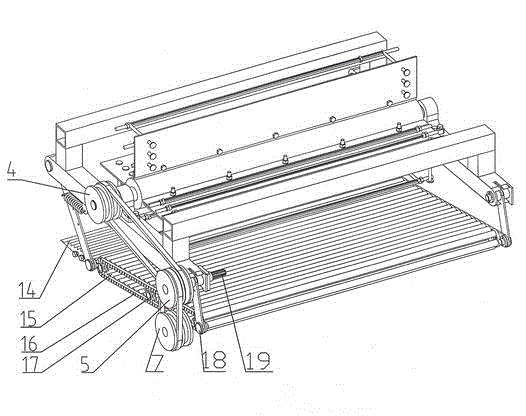

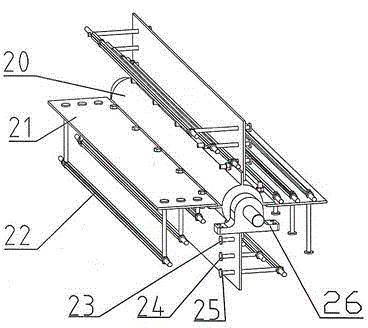

[0019] see figure 1 , figure 2 , image 3 and Figure 4 Shown, be the embodiment of the present invention, comprise frame 1, machine cover 2, last pick-up mechanism 3 and following pick-up mechanism 8, last pick-up mechanism 3 is fixed on the top of frame 1 by bearing seat 26, following pick-up mechanism 8 Be fixed on the bottom of frame 1 by bearing pin 18, machine cover 2 is installed on the top of last pick-up mechanism 3, and is fixed on the frame 1 by bolt; Frame 1 includes trailing arm 6, rocking arm 9, forearm 10, Limiting plate 11, spring 12, longitudinal beam 13, input pulley 5 and input shaft 19, the top of forearm 10 is fixed on the front portion of longitudinal beam 13 by pin 18, and the top of rear arm 6 is fixed on longitudinal beam by input shaft 19 13, the rocker arm 9 is respectively fixed on the lower part of the front arm 10 and the rear arm 6 through the pin shaft 19, the input pulley 5 is fixed on the outside of the input shaft 19 through the bearing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com