Full-automatic grafting machine

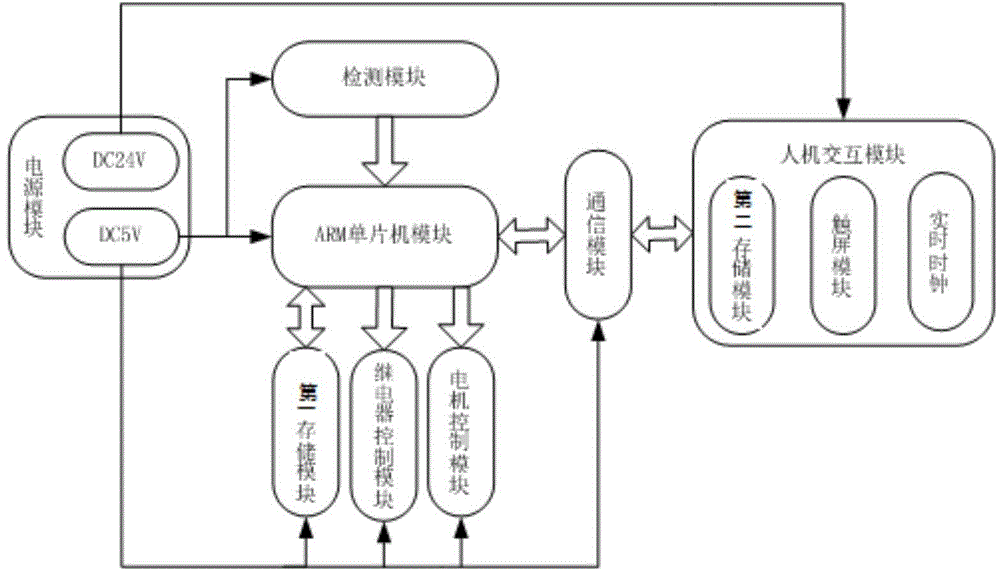

A kind of grafting machine, fully automatic technology, applied in horticulture, application, botany equipment and methods, etc., can solve the problems of inflexible setting, many wiring, and inability to fully automatic mode of grafting, so as to avoid the effect of mechanical transmission structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

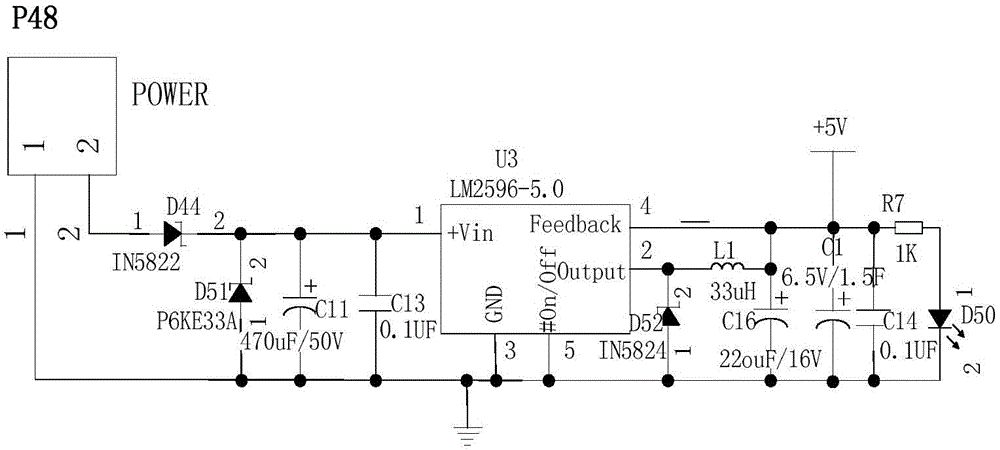

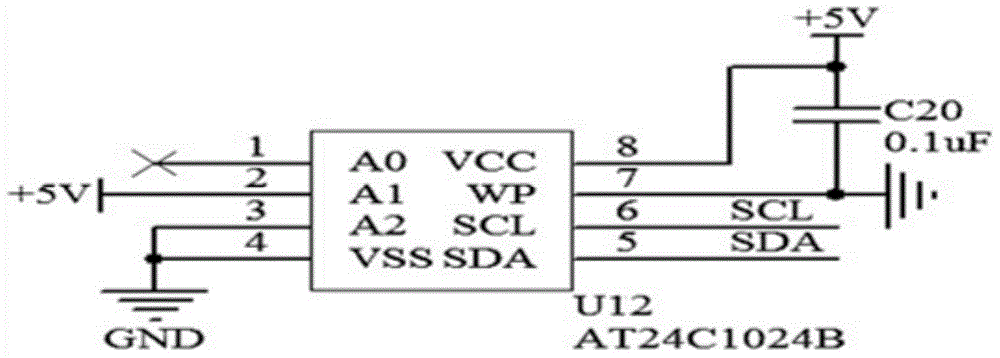

Method used

Image

Examples

Embodiment 1

[0066] A fully automatic grafting machine as shown in the figure, including: main platform 1, first sub-platform 2, second sub-platform 3, bracket 4, touch screen control box 7, motor installation platform 5, stepping motor, vibration plate 6. Clip guide rail 45, gripper 12, support beam 13, ear seedling conveying device 8, ear seedling pneumatic rotating arm 10, ear seedling pneumatic scissors and positioning device 11, rootstock conveying device 9, rootstock pneumatic rotating arm 15 and rootstock pneumatic Scissors 39 and positioning device 14;

[0067] The ear seedling conveying device 8 and the rootstock conveying device 9 are relatively installed on both sides of the main platform 1 respectively, the ear seedling pneumatic rotating arm 10 is slidably connected to the ear seedling conveying device 8, and the stock pneumatic rotating arm 15 is slidably connected to the rootstock conveying device 9; The supporting crossbeam 13 is located on the main platform 1 and is positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com