Visual multifunctional pilot scale test synthesis device

A synthetic equipment and multi-functional technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve problems that cannot be reflected intuitively, achieve intuitive viewing, improve students' hands-on ability, Awareness-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

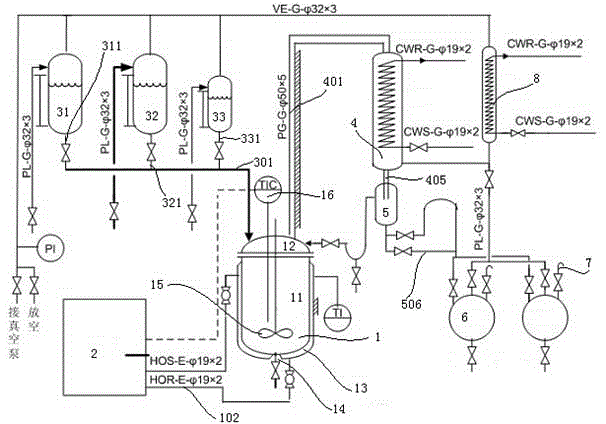

[0042] Such as figure 1 As shown, the salt-forming acidification equipment includes: a reaction kettle 1, the reaction kettle includes a kettle body 11, an upper cover 12, and a heat-conducting oil accommodating cavity 13 formed on the outside of the kettle body, and the reaction kettle upper cover 12 is provided with There is a feed hole and an observation hole for observation. The lower end of the reaction kettle 1 is provided with a discharge port 14. A stirrer 15 and a temperature display control device 16 are also installed in the reaction kettle; it also includes a heat transfer oil. Furnace 2, the heat-conducting oil furnace 2 is equipped with high-transparency heat-conducting oil, and the heat-conducting oil furnace communicates with the heat-conducting oil chamber outside the reactor body through a heat-conducting oil pipeline 102; it also includes a high-transparency glass high-level Feed tank, the high-level feed tank of high transparency glass includes a high-level...

Embodiment 2

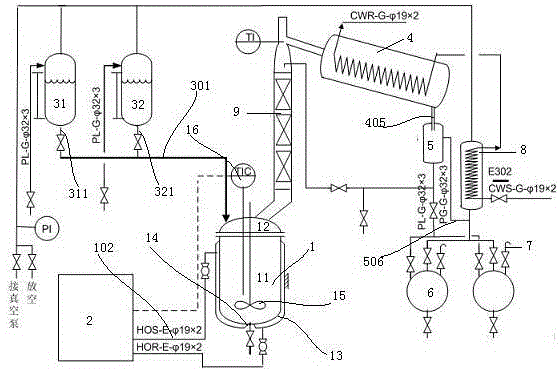

[0048] Such as figure 2 As shown, the rectification equipment includes: a reaction kettle 1, the reaction kettle includes a kettle body 11, an upper cover 12, and a heat-conducting oil accommodating cavity 13 formed on the outside of the kettle body, and the reaction kettle upper cover 12 is provided with Feed hole, the lower end of the reaction kettle 1 is provided with a discharge port 14, and a stirrer 15 and a temperature display control device 16 are also installed in the reaction kettle. Here, the reaction kettle is more accurately called a solvent rectification kettle. It also includes a heat-conducting oil furnace 2, which is equipped with a high-transparency heat-conducting oil, and is communicated with the heat-conducting oil accommodating cavity on the outside of the reactor body through a heat-conducting oil pipeline 102; Including a high-level feed tank of high-transparency glass, the high-level feed tank of high-transparency glass includes a high-level feed tank...

Embodiment 3

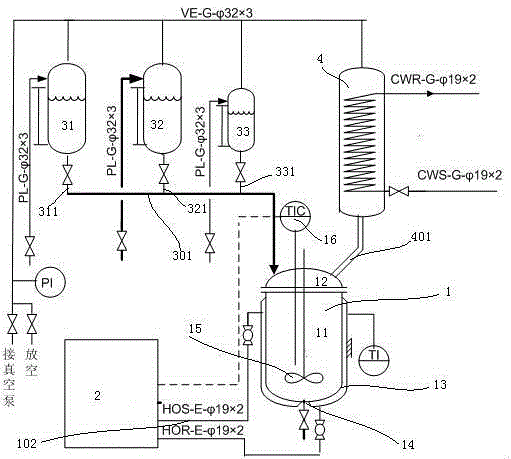

[0055] Such as image 3 As shown, the acylation equipment includes: a reaction kettle 1, the reaction kettle includes a kettle body 11, an upper cover 12, and a heat transfer oil accommodating cavity 13 formed on the outside of the kettle body, and the reaction kettle upper cover 12 is provided with a There is a feed hole, the lower end of the reactor 1 is provided with a discharge port 14, and an agitator 15 and a temperature display control device 16 are also installed in the reactor. In this embodiment, the reactor should be understood as an acylation reaction Kettle; also includes a heat-conducting oil furnace 2, the heat-conducting oil furnace 2 is equipped with high-transparency heat-conducting oil, and the heat-conducting oil furnace is communicated with the heat-conducting oil accommodating cavity outside the reactor body through a heat-conducting oil pipeline 102; It also includes a high-level feed tank of high-transparency glass. The high-level feed tank of high-tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com