A production process for rolling 82b wire rod without holes in a high-speed wire rod mill

A high-speed wire rod and production process technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of steel stripping, low processing cost, and reduced production accident rate, so as to reduce order weight and processing cost. The effect of low, production accident rate reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

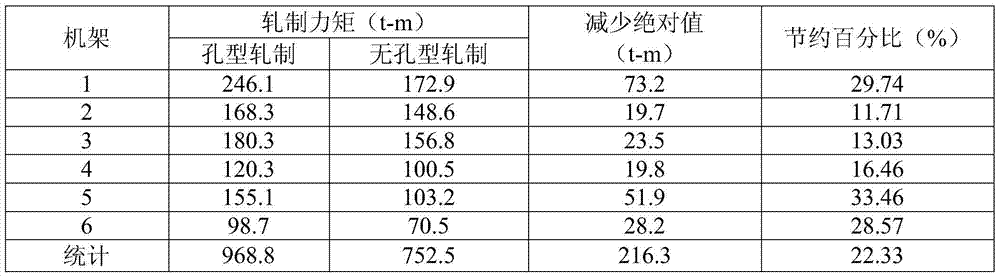

[0046] The production process of the high-speed wire rod mill without groove rolling 82B wire rod includes the following steps:

[0047] 1) Heating: using a walking heating furnace to heat a steel billet with a cross-sectional size of 150mm×150mm to 980°C;

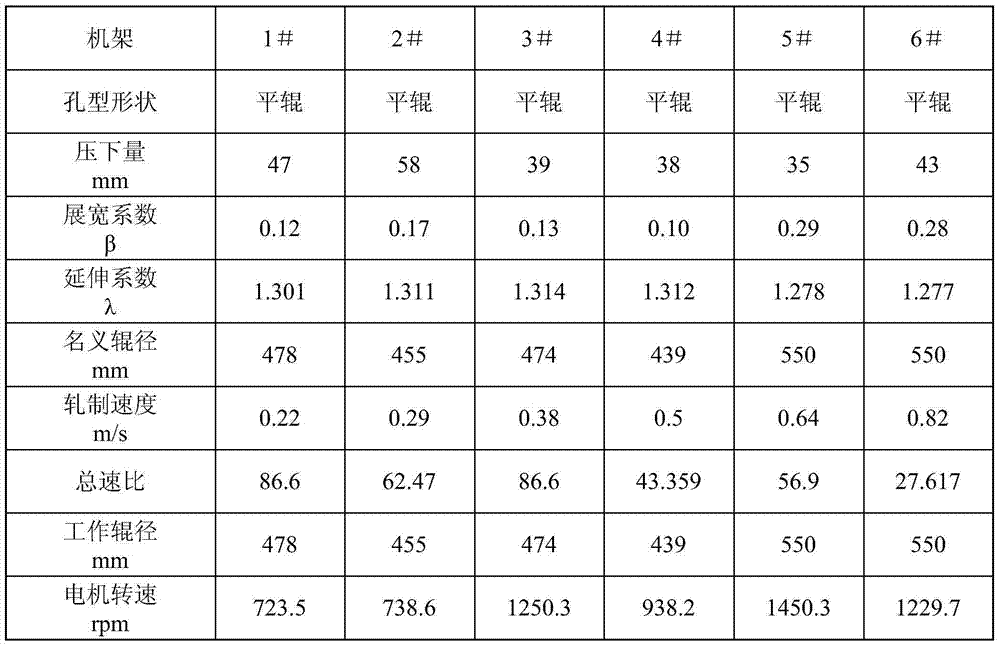

[0048] 2) No-hole rolling in the rough rolling unit: adopt flat roll rolling to carry out 6-pass rolling to the steel slab heated in step 1) to obtain a 60mm×60mm square steel. The exits are equipped with guides to guide the billet to enter and exit the rolling mill smoothly in the required direction and state. During the rolling process, the elongation coefficients of each pass are controlled as follows: the first pass is 1.304, the second pass is 1.361, and the third pass is 1.361. 1.304 for the fourth pass, 1.363 for the fourth pass, 1.31 for the fifth pass, and 1.258 for the sixth pass; the spread coefficient is 0.25-0.65, and the running speed of the billet during the rolling process is 0.205-0.816m / s;

[0049] 3) In...

Embodiment 2

[0059] 1) Heating: using a walking heating furnace to heat a billet with a cross-sectional size of 150mm×150mm to 1040°C;

[0060] 2) No-hole rolling in the rough rolling unit: adopt flat roll rolling to carry out 6-pass rolling to the steel billet heated in step 1) to obtain a 64mm×64mm square steel, and the rolling process of each rolling mill The exits are equipped with guides to guide the billet to enter and exit the rolling mill smoothly in the required direction and state. During the rolling process, the elongation coefficients of each pass are controlled as follows: the first pass is 1.301, the second pass is 1.312, and the third pass is 1.312. 1.318 for the fourth pass, 1.359 for the fourth pass, 1.275 for the fifth pass, and 1.388 for the sixth pass; the spread coefficient is 0.153-0.330, and the running speed of the billet during the rolling process is 0.20-0.82m / s;

[0061] 3) Intermediate rolling group and pre-finishing rolling group: use flying shears to cut off t...

Embodiment 3

[0069] The production process of the high-speed wire rod mill without groove rolling 82B wire rod includes the following steps:

[0070] 1) Heating: use a walking heating furnace to heat a billet with a cross-sectional size of 150mm×150mm to 1060°C;

[0071] 2) No-hole rolling in the rough rolling unit: adopt flat roll rolling to carry out 6-pass rolling to the steel slab heated in step 1) to obtain a 68mm×68mm square steel, and the rolling process of each rolling mill The exits are equipped with guides to guide the billet to enter and exit the rolling mill smoothly in the required direction and state. During the rolling process, the elongation coefficients of each pass are controlled as follows: the first pass is 1.301, the second pass is 1.311, and the third pass is 1.311. 1.314 for the fourth pass, 1.312 for the fourth pass, 1.278 for the fifth pass, and 1.277 for the sixth pass; the spread coefficient is 0.10-0.30, and the running speed of the billet during the rolling pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com