Pipe fitting notching die

A slit die and pipe fitting technology, applied in the field of pipe slit cold stamping die, can solve the problems affecting the production efficiency and product quality, the incision cannot be concentric, affecting the pipe fitting assembly effect, etc., so as to ensure product quality and production efficiency, The effect of simple structure and increased work frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

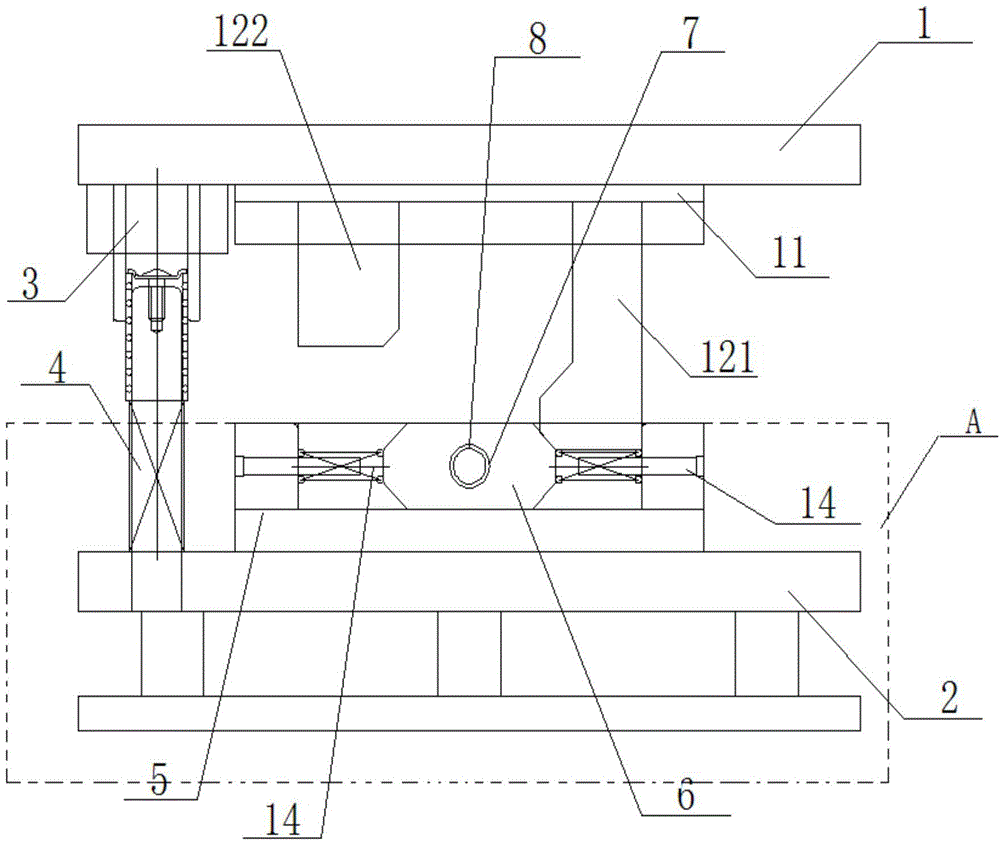

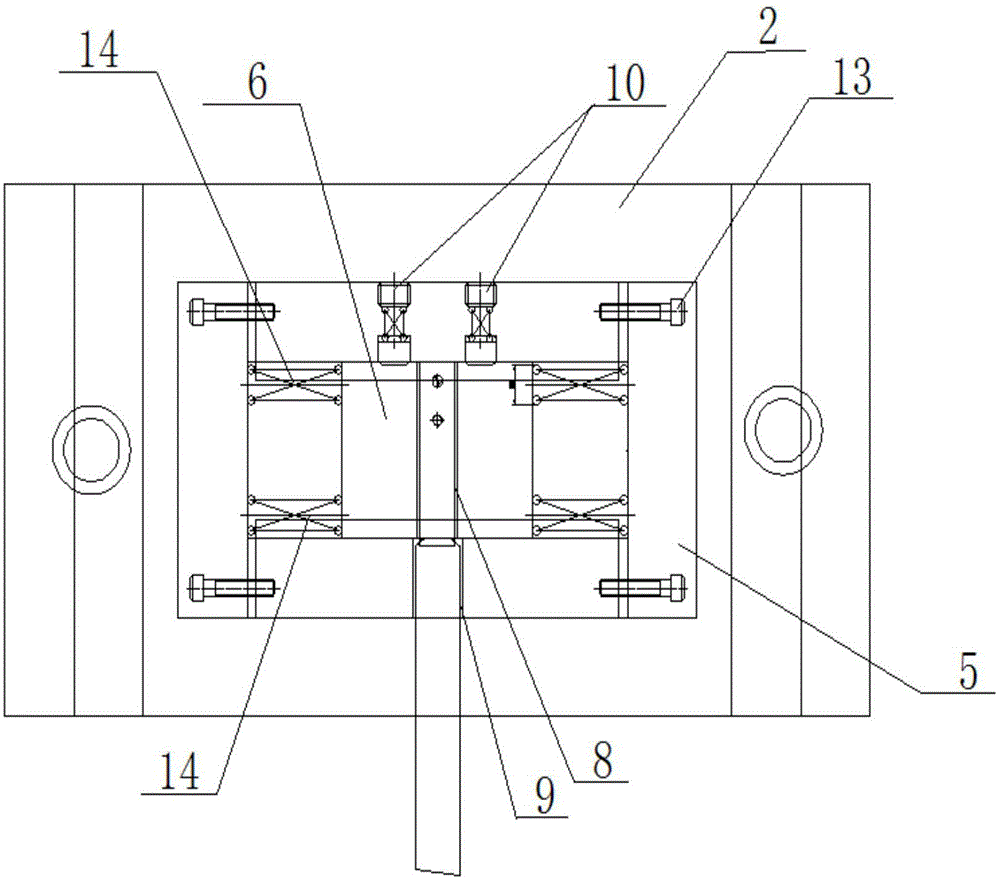

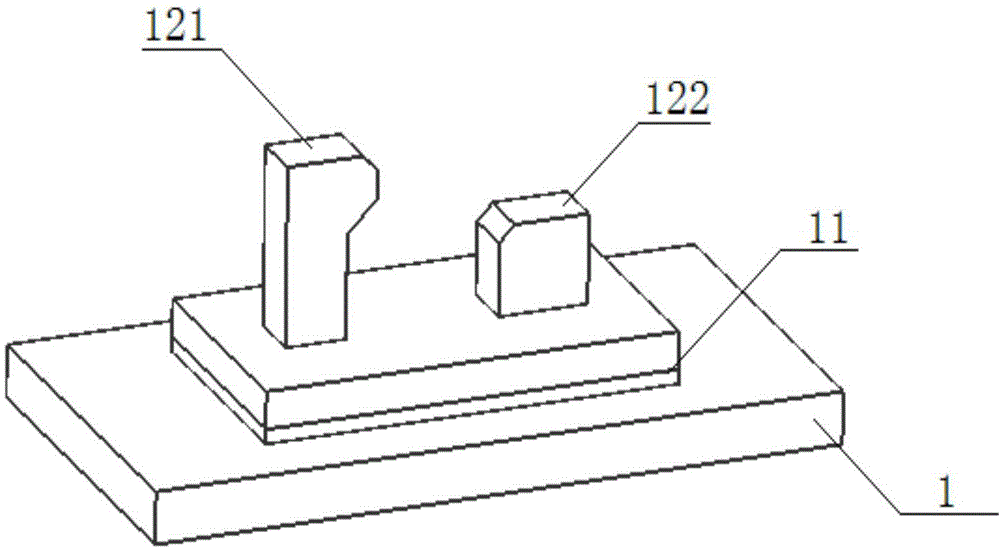

[0025] A pipe fitting notch die provided in this embodiment has a structure such as Figure 1-9 As shown, it mainly includes an upper formwork 1 and a lower formwork 2. The upper formwork 1 is arranged in parallel above the lower formwork 2 through the guide rod 3 and the spring sleeve 4. The lower formwork 2 is provided with a slider seat 5, and the slider seat 5 is provided with a Slider 6, between the two ends of the slider 6 in the length direction and the inner surface of the slider seat 5, springs are respectively provided to assist the reset of the slider 6, and a cylindrical shape with open ends is also hollowed out along the width direction of the slider 6. There is a mandrel 8 in the interference fit of the groove 7 and the cylindrical groove 7, and a pipe fitting through hole 9 is opened on one side of the slider seat 5, and the center line of the pipe fitting through hole 9, the mandrel 8 and the cylindrical groove 7 in a static state On the same straight line, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com