A kind of diamond composite sheet for oil drilling made by using nanometer metal bond and its preparation method

A diamond composite sheet and nano-metal technology, which is applied in the field of diamond composite sheets for oil drilling, can solve the problems of the limited sales price and application range of domestic composite sheets, achieve good sintering promotion effect, prolong service life, and increase impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A nanometer metal bond, which is composed of the following raw materials in weight percent: 99% Co powder, 0.5% NbC powder, 0.4% Ni powder and 0.1% Be powder. The particle size of NbC is 22-36nm, and the particle size of Co, Ni and Be powder is 18-22nm.

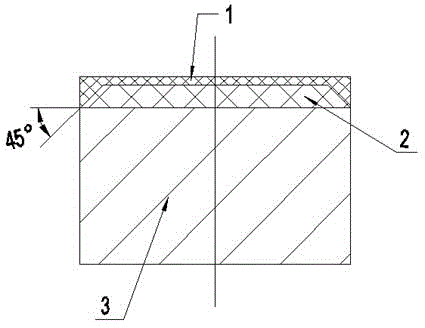

[0025] A diamond composite sheet for oil drilling made using the above-mentioned nano metal bond, the composite sheet includes a diamond layer and a cemented carbide matrix composed of a diamond polycrystalline layer and a transition layer; the diamond polycrystalline layer consists of the following weight Raw material composition in percentage: 98% of diamond powder (particle size 5-15μm) and 2% of nano-metal bond. The structure of the diamond compact is as figure 1 As shown, from top to bottom are diamond polycrystalline layer 1, transition layer 2 and cemented carbide substrate 3, the longitudinal section of the transition layer 2 is an isosceles trapezoid; the angle between the waist of the isosceles trapezoid and...

Embodiment 2

[0035] A nanometer metal bond, the nanometer metal bond is composed of the following raw materials in weight percentage: 97% of Co powder, 1% of NbC powder, 1.5% of Ni powder and 0.5% of Be powder. The particle size of NbC is 22-36nm, and the particle size of Co, Ni and Be powder is 18-22nm.

[0036] A diamond composite sheet for oil drilling made using the above-mentioned nano metal bond, the composite sheet includes a diamond layer and a cemented carbide matrix composed of a diamond polycrystalline layer and a transition layer; the diamond polycrystalline layer consists of the following weight Raw material composition in percentage: 92% of diamond powder (particle size 5-15μm) and 8% of nano-metal bond. The weight percentages of each layer of the diamond layer are: 35% of the diamond polycrystalline layer, and 65% of the transition layer. The transition layer is composed of the following raw materials in weight percentage: 85% of diamond powder (with a particle size of 15-3...

Embodiment 3

[0046] A nanometer metal bond, the nanometer metal bond is composed of the following raw materials in weight percentage: 98% of Co powder, 0.8% of NbC powder, 0.9% of Ni powder and 0.3% of Be powder. The particle size of NbC is 22-36nm, and the particle size of Co, Ni and Be powder is 18-22nm.

[0047] A diamond composite sheet for oil drilling made using the above-mentioned nano metal bond, the composite sheet includes a diamond layer and a cemented carbide matrix composed of a diamond polycrystalline layer and a transition layer; the diamond polycrystalline layer consists of the following weight Raw material composition in percentage: 94% diamond powder (particle size 5-15 μm) and 6% nano-metal bond. The weight percentages of each layer of the diamond layer are: 40% of the diamond polycrystalline layer, and 60% of the transition layer. The transition layer is composed of the following raw materials in weight percentage: 90% of diamond powder (with a particle size of 15-35 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com