Automobile part laser marking device

A technology of laser marking and auto parts, which is applied in laser welding equipment, printing, manufacturing tools, etc., can solve the problems that manual and mechanical marking cannot meet the batch requirements, and achieve speed improvement, improve marking accuracy and speed, The effect of reducing production and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

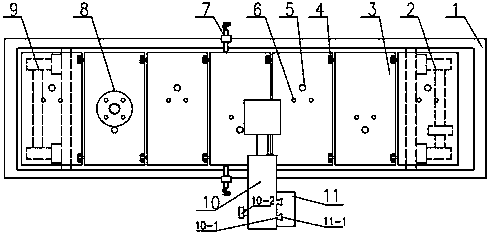

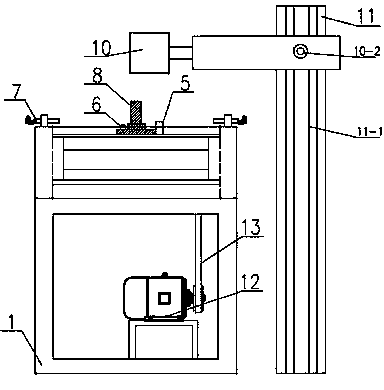

[0011] Depend on figure 1 , figure 2 Know, the schematic diagram of the present invention, by main body support 1, driving sprocket assembly 2, chain row 3, connecting pin 4, positioning column 5, fixing column 6, infrared probe 7, workpiece 8, driven sprocket assembly 9, marking Machine head 10, protruding structure 10-1, adjustment knob 10-2, marking machine bracket 11, groove 11-1, driving motor 12, driving chain 13, driving motor 12 is fixed under the main body bracket 1, active The sprocket assembly 2 is fixed on the right position above the main body support 1, the driving sprocket assembly 2 is connected together with the drive motor 12 through the drive chain 13, and the driven sprocket assembly 9 is fixed on the left position above the main body support 1, from The moving sprocket assembly 9 and the driving sprocket assembly 2 are on the same horizontal line, and the infrared probe 7 is arranged on the upper part of the main body bracket 1 and distributed symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com