Anti-collision vessel with elastic frame structure

A frame structure and elastic frame technology, applied in the direction of anti-collision, substructure, non-magnetic metal hull, etc., can solve the problems of cracking, damage, and desoldering of rigid ships, so as to enhance elastic deformation, enhance safety factor, and avoid ship hull. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

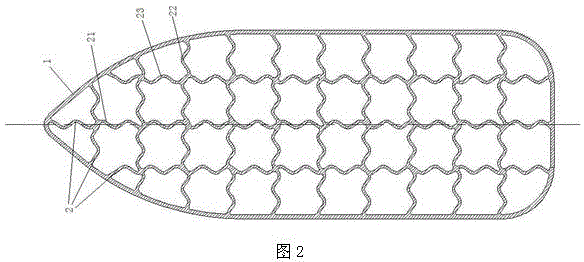

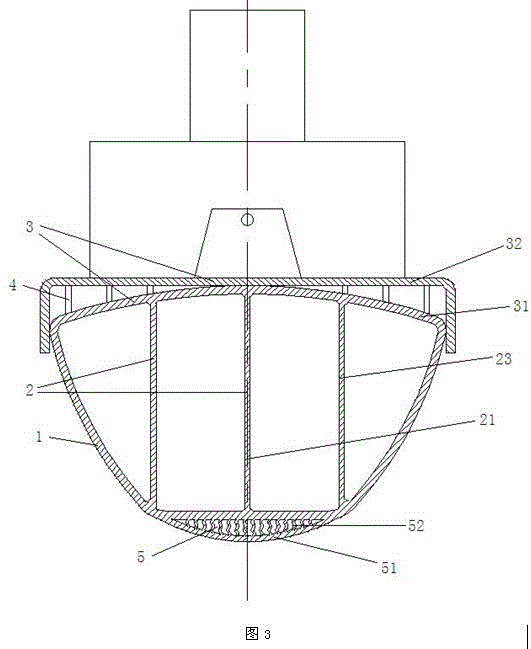

[0020] Such as figure 1 , 2 , 3. As shown in the anti-collision ship with elastic frame structure, its hull structure is an integral elastic frame structure, and the hull 1, skeleton 2 and deck 3 of the ship are made of elastic high-strength materials. The hull 1 It is in the shape of an elliptical arc, the skeleton 2 is arc-shaped or wave-shaped along its trend, and the deck 3 is a double-layer structure.

[0021] The optimal design of the hull structure is an integral elastic frame structure without stress concentration points, and the hull 1 is in the shape of a circular arc or an elliptical arc.

[0022] The skeleton 2 includes keels 21, ribs 22, side keels 23, structural ribs and plates, all of which are arc-shaped or wave-shaped along their respective trends.

[0023] The deck 3 is a double-layer structure, and the lower deck 31 is an arc-shaped turtle-like structure connected to the hull 1 and the frame 2, together with the hull 1 and the frame 2, it forms the elastic...

Embodiment 2

[0028] Such as Figure 4 As shown, a layer of elastic protective layer 5 is added to the easy-to-collision part of the existing ship (in this embodiment, both sides of the hull). , made of spring steel or elastic stainless steel or low alloy high elastic steel. The internal skeleton 52, reinforcing ribs, and plates are all made into arcs or waves along the trend, and the connection between the arc-shaped shell 51 of the elastic protective layer 5 and the original shell of the hull adopts a smooth and excessive tangential connection, eliminating The point of stress concentration is increased, the impact strength of the external force is enhanced, and the ship with the elastic protective layer 5 is improved. When being hit, the elastic protective layer 5 at the impact is elastically deformed, buffering and absorbing the impact energy, so that the impact force is transmitted to the hull. Even the energy of the hull is greatly weakened, which enhances the crashworthiness of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com