Automatic anchoring device

An automatic and dynamic technology, which is applied in transportation and packaging, anchoring treatment/lashing, ship parts, etc., can solve the problems that safety hazards cannot be completely eliminated, anchor chains or cables hurt people, and cumbersome operations, etc., to simplify the anchoring operation process , Reduce labor intensity and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

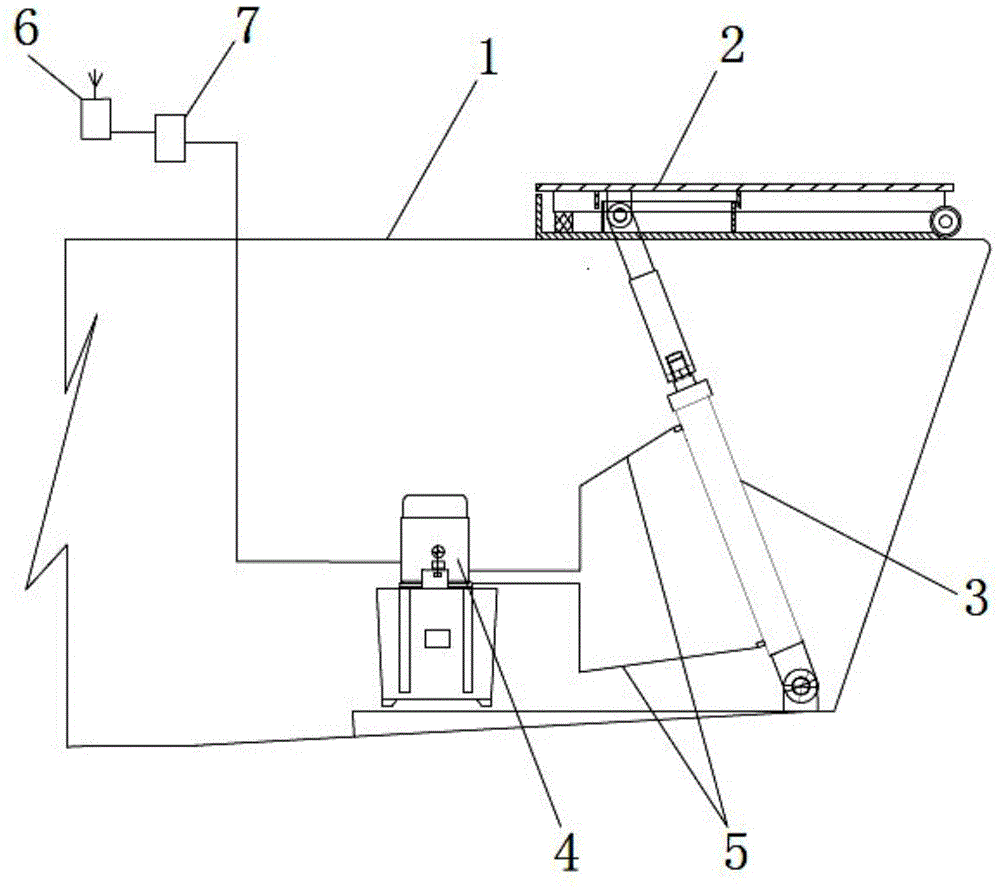

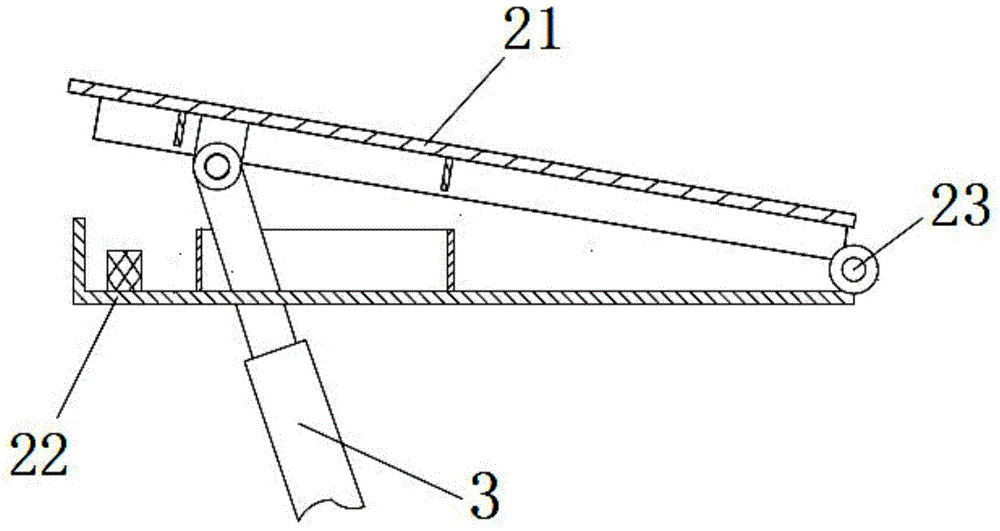

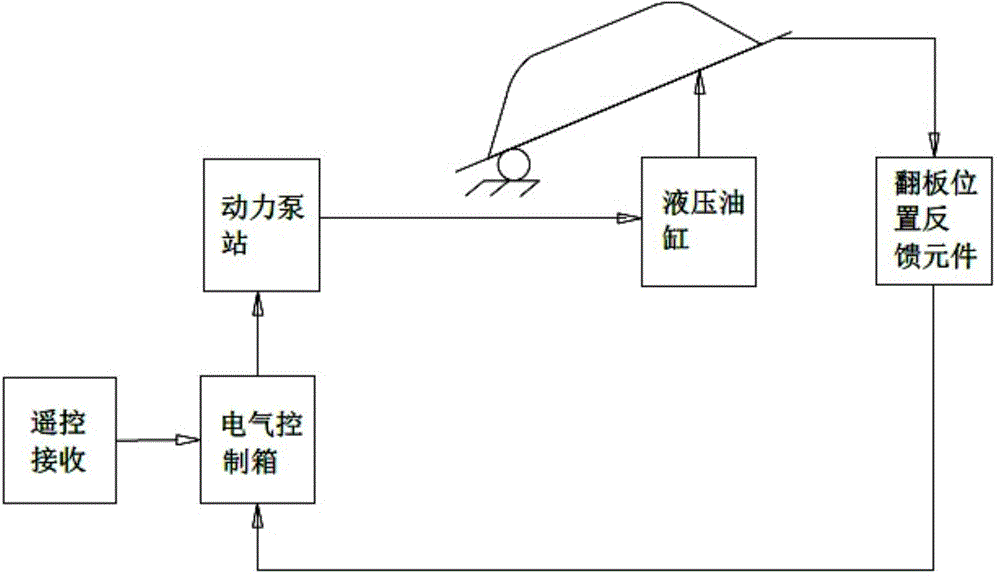

[0020] Automatic anchoring device of the present invention, as figure 1 As shown, it includes a turnover mechanism 2 located on the main deck 1, the turnover mechanism 2 is connected with a hydraulic cylinder 3 to control its turnover, the inlet and outlet of the hydraulic cylinder 3 are respectively connected to the power pump station 4 through oil pipes, and the power pump Station 4 is connected to electrical control box 6 through a control circuit. The power pump station 4 provides hydraulic power, and converts electric energy into hydraulic pressure energy to push the turnover mechanism to turn over.

[0021] In the present invention, the power pump station 4 includes a hydraulic pump, an oil tank and a hydraulic valve. The electric motor drives the hydraulic pump to pump oil, and the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com