Preparation method and storage method of 1-methyl cyclopropene lithium

A technology of lithium methylcyclopropene and methyl propylene, which is applied in the direction of lithium organic compounds, can solve problems such as instability, and achieve the effects of easy operation, stable reaction, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

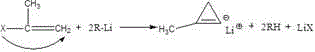

Method used

Image

Examples

Embodiment 1

[0019] Example method of synthesizing 1-methylcyclopropene lithium with lithium diisopropylamide: add 100ml of 1.5mol / l lithium diisopropylamide (0.15mol) into a 250ml four-necked reaction flask, and heat to 45 degrees Celsius Then add 0.4g of catalyst hexamethyldisilazane and 0.204g of triethylamine, prepare 6.795g of 3-chloro-2-methylpropene, put it into the constant pressure funnel, and add it dropwise at a constant speed, preferably controlled within about 1 hour Addition is complete. React for 1 hour after the dropwise addition is completed. After the reaction is completed, the sample is vacuumed and distilled at a pressure of 0.1 mpa. Distill for 1 hour. The specific time is determined according to the actual situation. Take 0.3g sample in Erlenmeyer flask, then add 40ml water, shake for about 5 minutes, gas phase, analysis result gas purity is 98.43%, containing a small amount of cyclohexane.

[0020]

Embodiment 2

[0022] Synthesis of 1-methylcyclopropene lithium with lithium diisopropylamide Example method: add 100ml of 1.5mol / l lithium diisopropylamide (0.15mol) to a 250ml four-necked reaction flask, and heat to 40 degrees Celsius Then add 0.4g of catalyst hexamethyldisilazane and 0.204g of triethylamine, prepare 4.08g of 3-chloro-2-methylpropene, put it into the constant pressure funnel, and add it dropwise at a constant speed, preferably controlled within about 1 hour Addition is complete. After the dropwise addition, react for 0.5 hours. After the reaction is completed, the sample is vacuumed and distilled at a pressure of 0.1 mpa. Distill for 0.5 hours. The specific time is determined according to the actual situation. Take 0.3g sample in Erlenmeyer flask, then add 40ml water, shake for about 5 minutes, gas phase, analysis result gas purity is 98.39%, containing a small amount of cyclohexane.

[0023]

Embodiment 3

[0025] Synthesis of 1-methylcyclopropene lithium with lithium diisopropylamide Example method: Add 100ml of 1.5mol / l lithium diisopropylamide (0.15mol) into a 250ml four-necked reaction flask and heat to 50 degrees Celsius Then add 0.4g of catalyst hexamethyldisilazane and 0.204g of triethylamine, prepare 5.1g of 3-chloro-2-methylpropene and put it into a constant pressure funnel, add it dropwise at a constant speed, preferably within about 1 hour Addition is complete. React for 1 hour after the dropwise addition is completed. After the reaction is completed, the sample is vacuumed and distilled at a pressure of 0.1 mpa. Distill for 1 hour. The specific time is determined according to the actual situation. Take 0.3g sample in Erlenmeyer flask, then add 40ml water, shake for about 5 minutes, gas phase, analysis result gas purity is 98.29%, containing a small amount of cyclohexane.

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com