Preparation method of fire-retardant EPS foam insulation board and board thereof

The technology of thermal insulation board and board is applied in the field of preparation of flame retardant polystyrene foam thermal insulation board and flame retardant polystyrene foam thermal insulation board, which can solve the problem of long production cycle, difficulty in improving the fire rating of polystyrene foam board, and fire retardant. Uniform coating and other problems, to achieve the effect of short production cycle, overcoming long molding cycle and improving fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

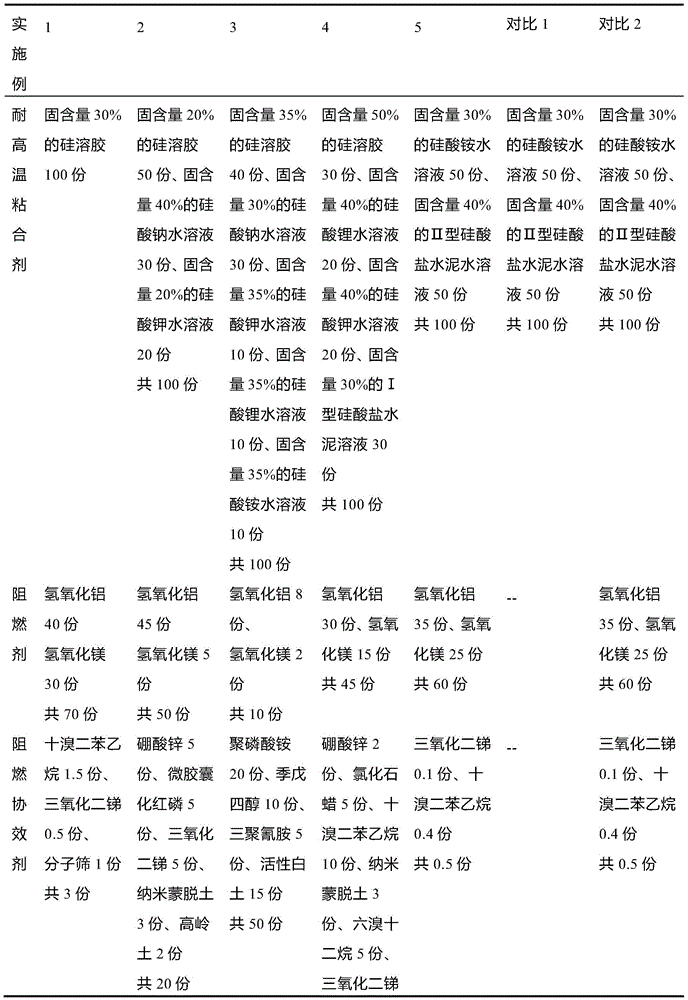

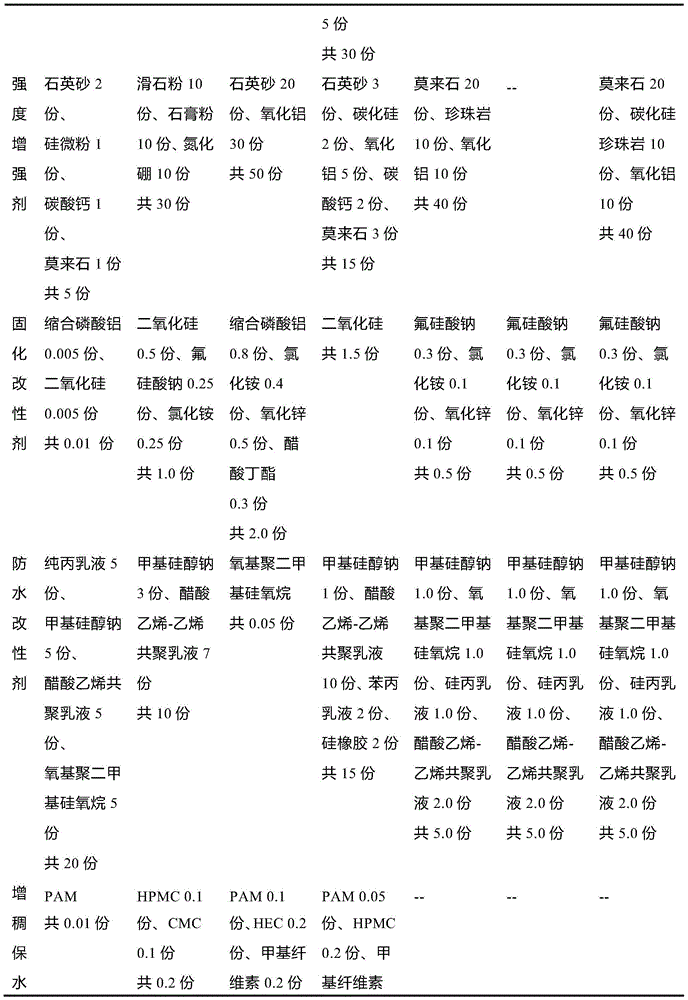

Embodiment 1~5 and comparative Embodiment 1~2

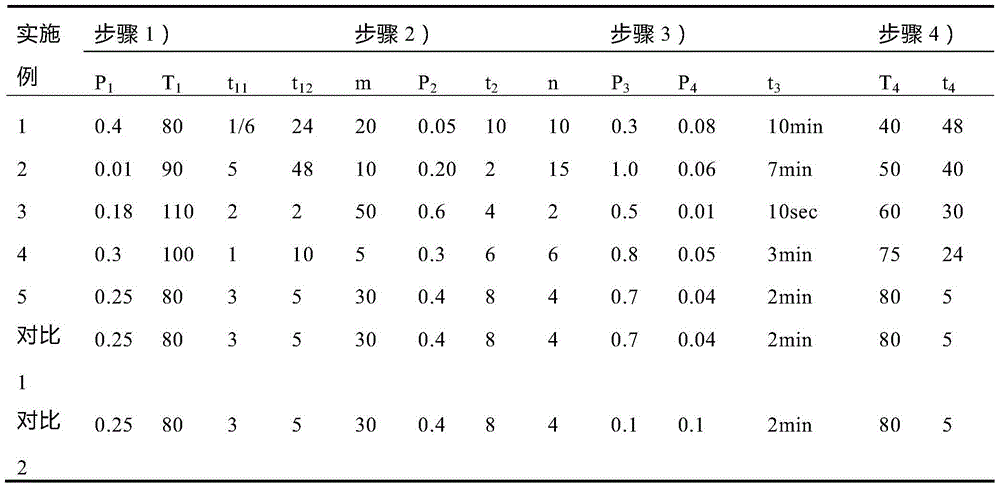

[0039] Step 1) Prepare flame-retardant polystyrene pre-sent particles

[0040] Put the flame-retardant expandable polystyrene into the pre-expanding machine, and control the steam pressure P 1 Mpa, temperature T 1 ℃, pre-foaming t 11 Minutes to obtain flame-retardant expandable polystyrene, drying and curing t 12 hours, to obtain flame-retardant polystyrene pre-issued particles.

[0041] Step 2) Prepare flame-retardant polystyrene foam board

[0042] Inhale m parts of flame-retardant polystyrene pre-issued particles into the steam forming machine, at P 2 Under the steam pressure of Mpa, preheating t 2 Minutes, the steam penetrates n times to prepare a flame-retardant polystyrene foam board.

[0043] Step (3) coating modification

[0044] Put the flame-retardant polystyrene foam board in the benzene board modification equipment, and then put the fire-resistant adhesive formulated in Table 2 in P 3 Under the high pressure of MPa, it is added to the benzene board modifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com