Large-span vault construction method and device

A construction device and large-span technology, applied in separation methods, chemical instruments and methods, petroleum industry, etc., can solve the problems of demolition, large wood consumption, multiple frame and other problems, so as to improve the quality, improve the quality of masonry, reduce the The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with embodiments and drawings.

[0025] A large-span vault construction method, which includes the following steps:

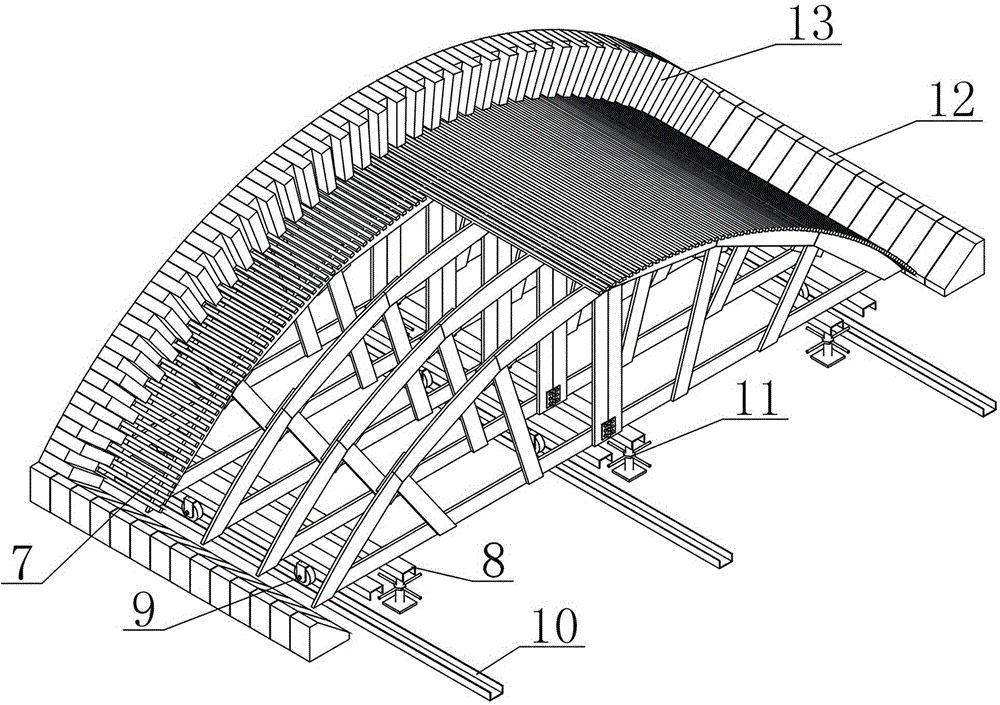

[0026] The first step is to install the double-beam frame 8 on the construction platform: three rails 10 are arranged in parallel along the length direction on the construction platform under the vault, and the length of each rail 10 is equal to the length of the vault; on each rail 10 Place a double beam frame 8;

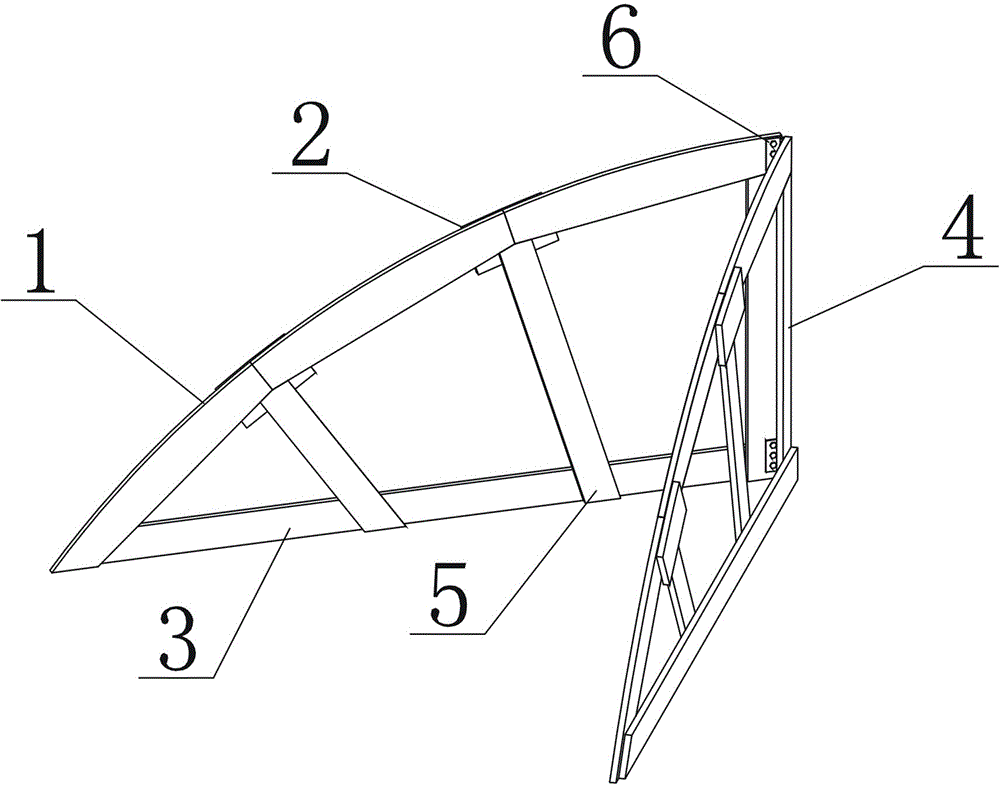

[0027] The second step is to install several tire frames on the double beam frame 8, which are arranged parallel and equidistant, and the distance between adjacent tire frames is not more than 0.65 meters;

[0028] The third step is to lay a layer of tire strip 7 on the top surface of the tire frame;

[0029] The fourth step is to lift up all the double-beam frames 8 with multiple supports 11 so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com