Automobile connection rod and thermal treatment process thereof

A technology of heat treatment process and automobile connecting rod, which is applied in the direction of heat treatment furnace, heat treatment equipment, connecting rod, etc., and can solve the problems of danger in the driving process, high frequency of use, easy wear and fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

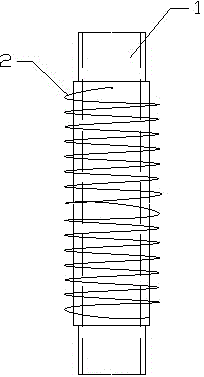

[0008] As shown in the figure, the present invention includes a body 1 and a heat treatment process, the body 1 is set as a cylindrical structure, the middle part of its outer ring is set as a round hole, and the winding spring structure 2, its heat treatment process includes its Quenching and tempering at medium temperature are carried out to obtain the tempered troostite structure. The choice of quenching temperature in the process is to ensure sufficient austenitization and maintain finer grains. Grain refinement can significantly improve the spring The impact value of steel, in order to develop high-strength spring steel, carbonitrides of trace alloying elements are added to the steel, which can refine austenite grains during heat treatment, and can also produce precipitation strengthening effects, and finally annealing .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com