Straight down type backlight source module

A backlight, direct-type technology, applied in the field of direct-type backlight module, can solve problems such as brightness drop, influence on light mixing, thermal quenching of phosphor powder, etc., to reduce the light mixing distance, save the number of light sources, light Evenly spread effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

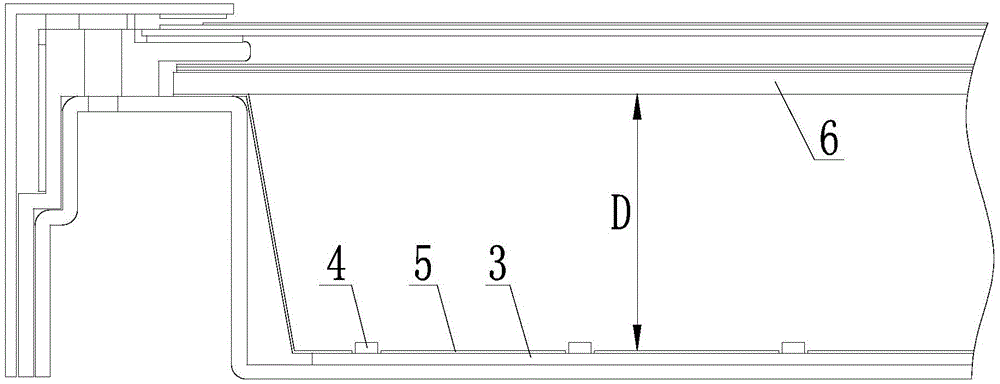

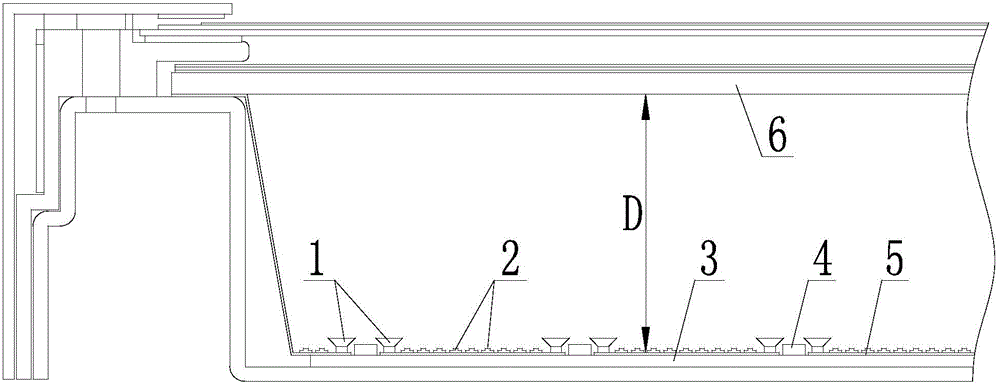

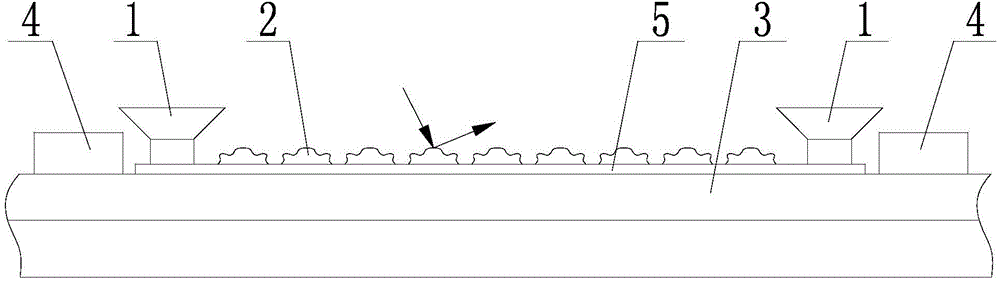

[0033] The direct type backlight module in this embodiment, such as Figure 2-Figure 6 As shown, it includes a light source 4, a back plate 3, a reflection sheet 5, a diffusion plate 6, a light scattering device 1 and diffusion particles 2, the reflection sheet 5 is located above the back plate 3, the diffusion plate 6 is located above the reflection sheet 5, and the light source 4 is located Between the back plate 3 and the diffusion plate 6 ; the light scattering device 1 is arranged around the light source 4 and between the back plate 3 and the diffusion plate 6 ; the diffusion particles 2 are all arranged on the reflection sheet 5 .

[0034] In this embodiment, the astigmatism device 1 is a trumpet-shaped structure, including a large end and a small end, and the small end is fixedly connected to the back plate 3, as image 3 and Figure 4 shown; and the astigmatism device 1 is evenly arranged on the backplane 3, as Figure 5 and Figure 6 shown.

[0035] In order to fu...

Embodiment 2

[0040] The difference between the backlight module in this embodiment and the first embodiment is that the structure of the astigmatism device is different. The astigmatism device 1 in this embodiment is a mushroom-shaped structure, such as Figure 7 As shown, including a spherical surface and a flat surface, the spherical surface is arranged upwards, which can also achieve the purpose of spreading the light more uniformly in the first embodiment, that is, reducing the light mixing distance and realizing the ultra-thinning of the backlight module. Furthermore, the number of LED light sources can also be reduced.

[0041] It should be noted that, in the above two embodiments, the structure of the light astigmatism device 1 is not limited to the trumpet-shaped structure in the first embodiment and the mushroom-shaped structure in the second embodiment, but can also be other existing known shapes and structures.

[0042] The arrangement of the astigmatism device 1 is not limited ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com