Metal film optical detection device and detection method

An optical detection and metal film technology, which is applied in the direction of using optical devices, measuring devices, and optical testing for flaws/defects, can solve problems such as metal film surface damage and probe metal film contact, so as to avoid contact, avoid damage, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

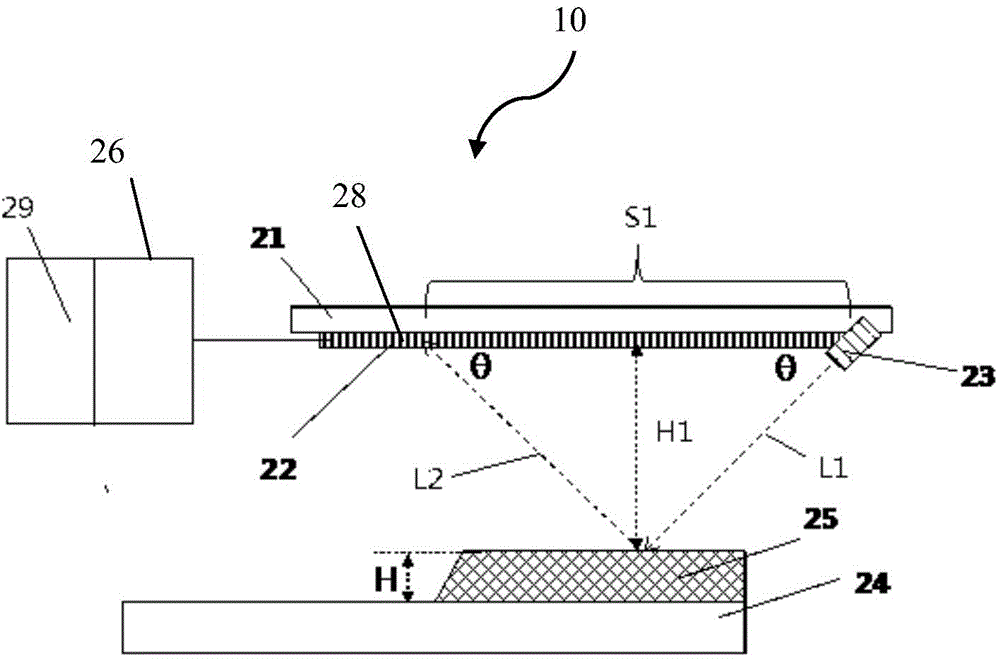

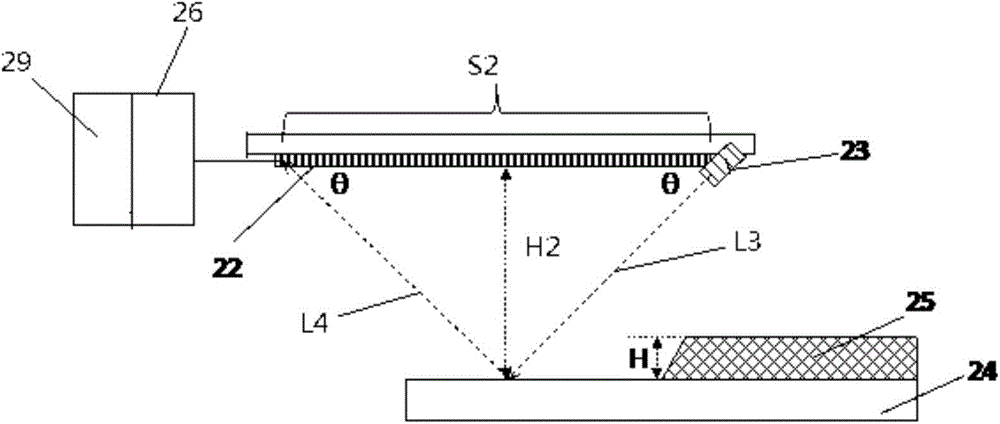

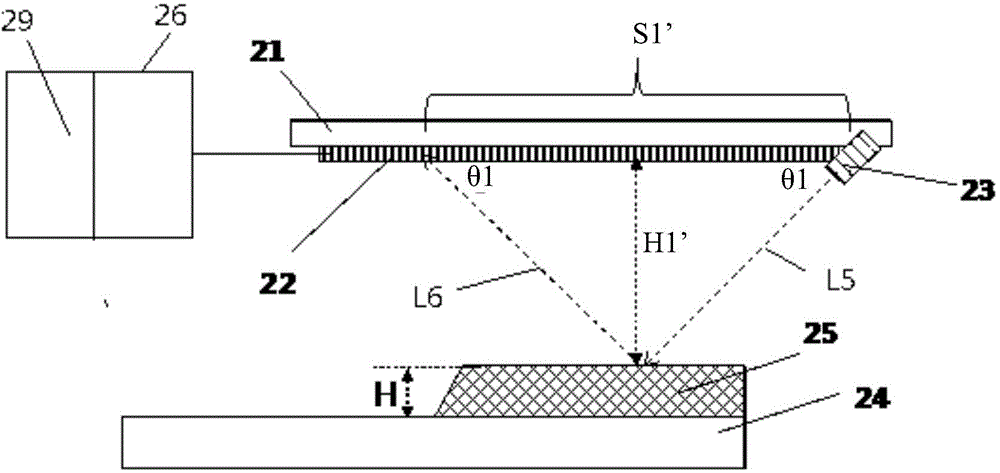

[0027] figure 1 with figure 2 Schematically shows the principle of using the metal film optical detection device 10 of the present invention (hereinafter referred to as the device 10 ) to measure the thickness of the metal film. Firstly, the components included in the device 10 will be described: a carrier 21 , a photosensitive sensor 22 and a light source 23 arranged on the carrier 21 , and an analysis unit 26 connected to the photosensitive sensor 22 . Such as figure 1 or figure 2 As shown, when the device 10 is used, the light source 23 obliquely faces the metal film 25 and the substrate 24 , so that the incident light beam L1 strikes the metal film 25 and the substrate 24 at an angle θ with the carrier 21 . The photosensitive sensor 22 also faces the metal film 25 and the substrate 24 with measurement to receive the reflected light beam L2 from the metal film 25 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com